Technology for rapidly cutting spray rail without pollution

A fast cutting, pollution-free technology, used in manufacturing tools, metal sawing equipment, metal processing equipment, etc., can solve the problems of energy consumption, safety, reliability, cutting time, etc., to reduce energy consumption, protect the saw blade, and simplify manual operation. The effect of the program that advances the main ingredient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

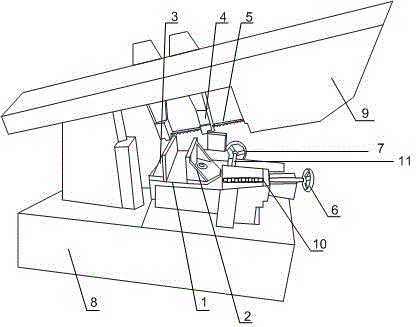

[0020] Such as figure 1 As shown, a method for clamping and clamping logs in the present invention is realized through the following steps: the clamping mechanism in step (A) includes a fixed baffle 3, a moving baffle 2, a first hand wheel 6, The first screw rod 10 and the connecting plate, the fixed baffle plate 3 is fixed on the connecting plate, the movable baffle plate 2 is slidably arranged on the connecting plate, the fixed baffle plate and the movable baffle plate 2 are relatively arranged on the operating table of the machine tool, and the first screw rod 10 Set in the connection plate and rotate with the connection plate through threaded cooperation, the first handwheel 6 is connected with one end of the first screw 10, the other end of the first screw 10 is in contact with the moving baffle 2, and the connection plate is slidably set on the machine tool 8 On the operating table and connected with the adjustment mechanism, the first hand wheel 6 is rotated, and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com