A conveying and cutting mechanism for earmuff outer skin

A cutting mechanism and skin technology, applied in leather punching/punching/cutting, small raw hide/large raw hide/leather/fur mechanical treatment, application, etc., can solve problems such as low efficiency and poor cutting effect, and achieve high efficiency , High cutting efficiency, the effect of meeting the cutting requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

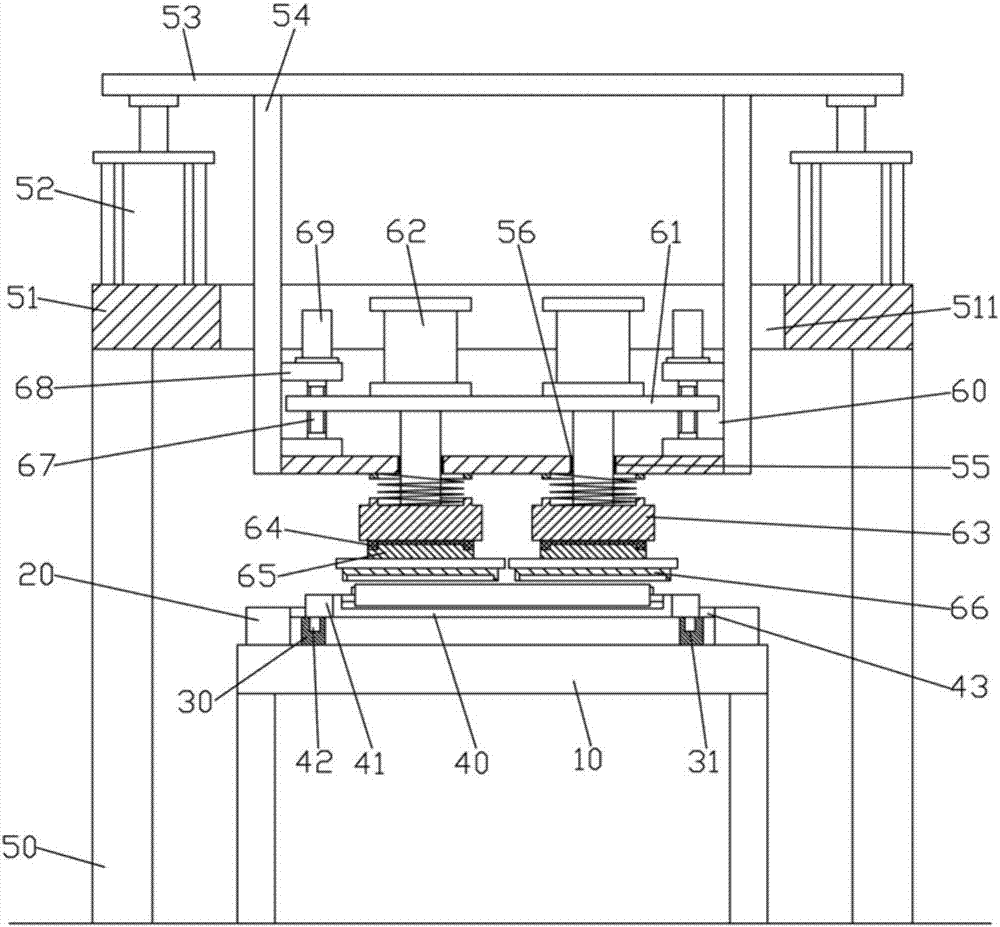

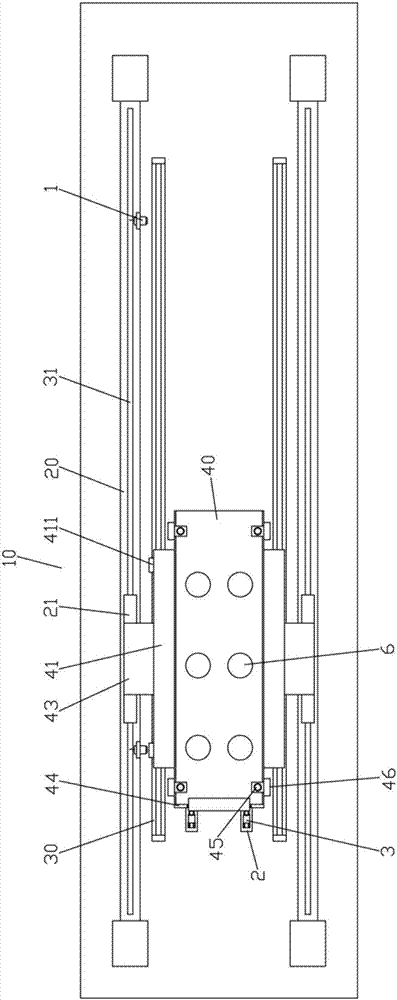

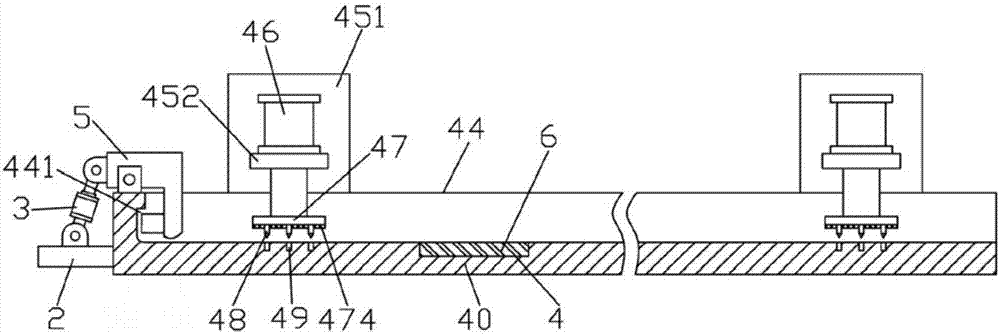

[0025] Examples, see e.g. Figure 1 to Figure 4 As shown, a transporting and cutting mechanism for earmuff cortex includes a transporting support frame, support columns 50 are fixed on the ground on both sides of the transport support frame, upper support plates 51 are fixed on the support columns 50, and the transport support frame Rodless cylinders 20 are fixed on the front and rear sides of the top plate 10, two parallel slide rails 30 are fixed on the top plate 10 between the two rodless cylinders 20, and the leather material placement plate 40 is between the two slide rails 30. The front and rear sides of the leather placing plate 40 are fixed with moving blocks 41, and the raised blocks 42 at the bottom of the moving block 41 are inserted into the chute 31 provided on the upper plane of the slide rail 30, and the two moving blocks 41 are fixed with A connecting block 43, the connecting block 43 is fixed on the sliding block 21 of the rodless cylinder 20;

[0026] The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com