Air compression type arc extinction device and high-voltage circuit breaker with arc extinction device

An arc extinguishing device and cylinder pressure technology are applied in the fields of high-voltage circuit breakers and compressed air arc extinguishing devices, which can solve the problems of high structural performance and operating device requirements of arc extinguishing devices, large operating power, etc., so as to prolong the service life and facilitate the Effects of Manufacturing and Assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

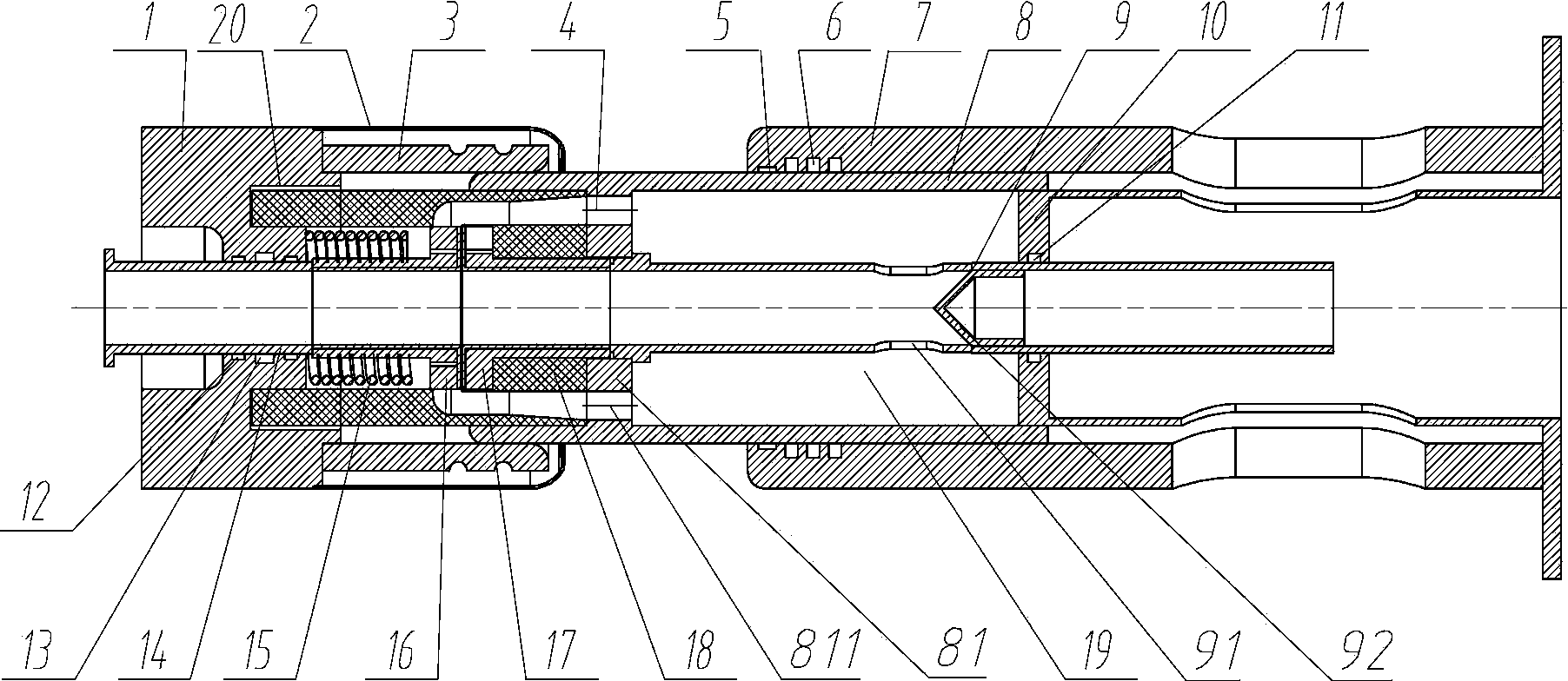

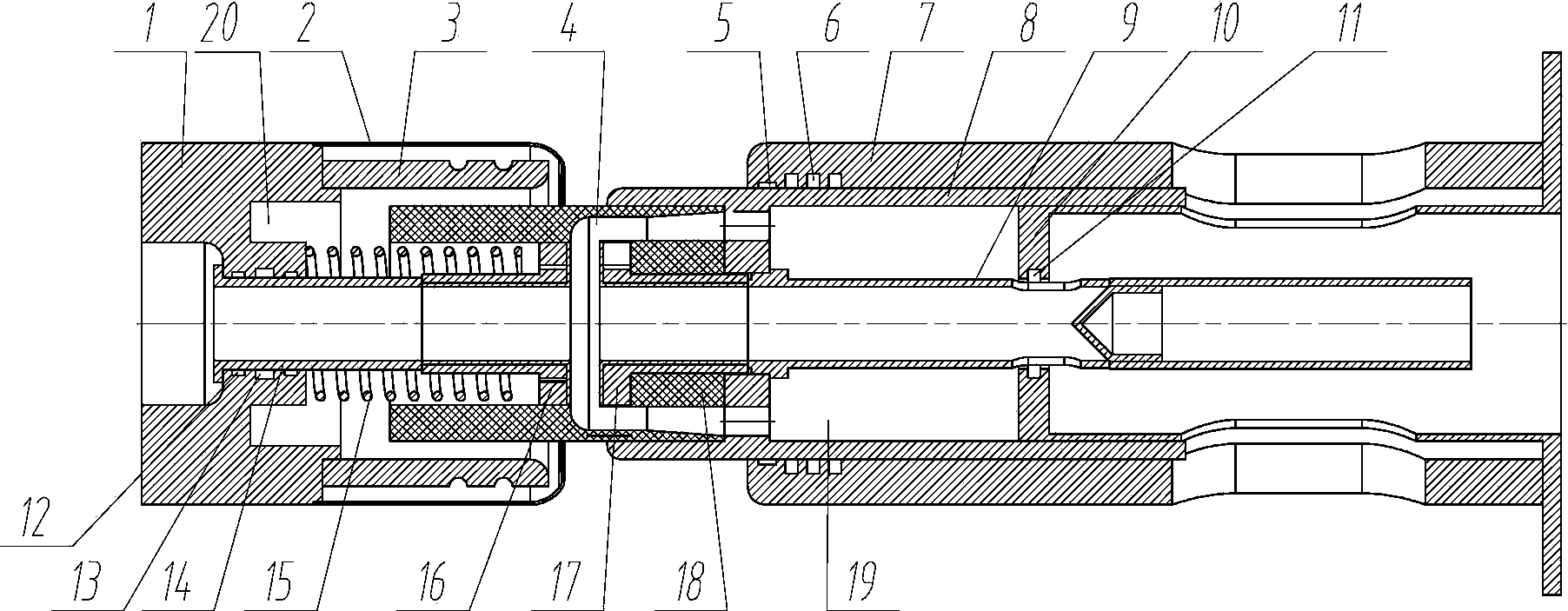

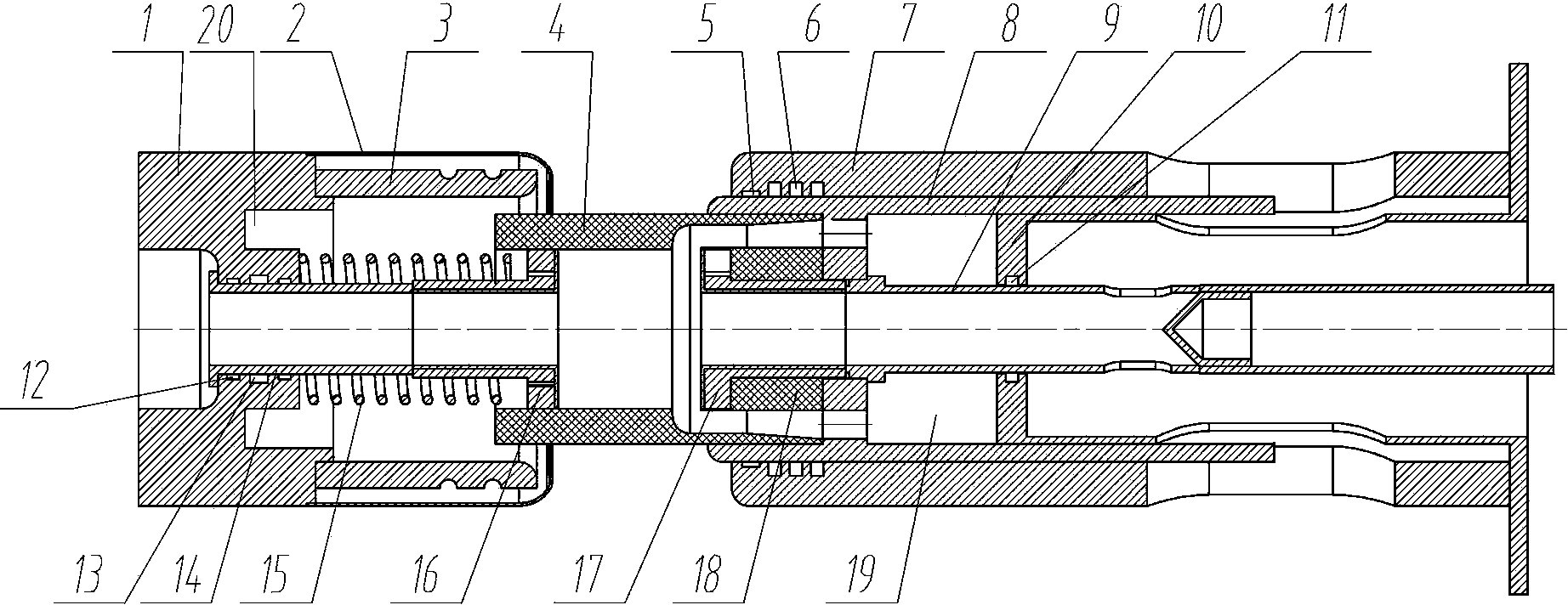

[0024] An embodiment of the medium pressure gas arc extinguishing device of the present invention is Figure 1~Figure 6 shown, is a SF 6 The arc extinguishing chamber includes a static end assembly and a moving end assembly, wherein the static end assembly includes a static contact seat 1, a static end shield 2, a static main contact 3 and a static arc contact 16, and the moving end assembly includes a moving end conductor 7, The support base 10 and the pressure cylinder 8, nozzle 4, moving arc contact 17 and pull rod 9 fixedly assembled together, the end of the pressure cylinder 8 close to the static end assembly constitutes the moving main contact for conducting with the static main contact 3 head.

[0025]The assembling method of the static contact seat 1 , the static end shield 2 and the static main contact 3 is the prior art, and will not be described in detail here. The static arc contact 16 includes a contact cylinder 21 with an axial through hole, and a flange extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com