Gas separation unit

A technology of gas separation and gas inlet, applied in the direction of fractionation, can solve the problems of poor gas separation effect and insufficient gas-liquid contact, etc., and achieve the effect of reducing insufficient gas-liquid contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

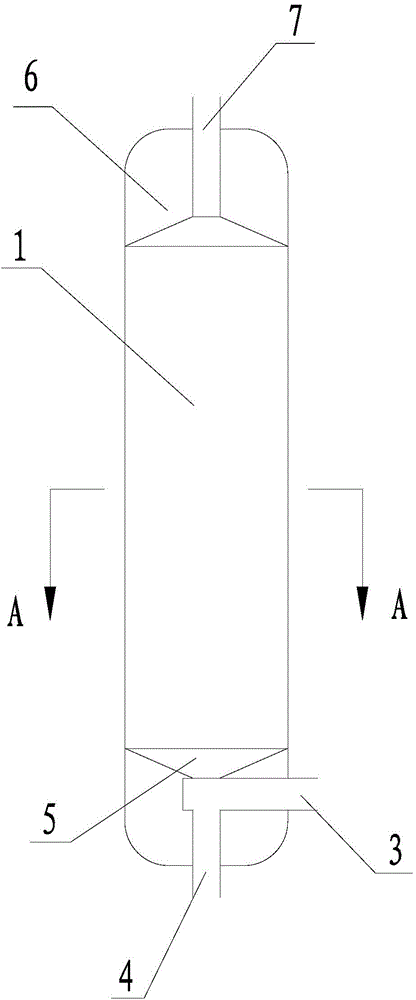

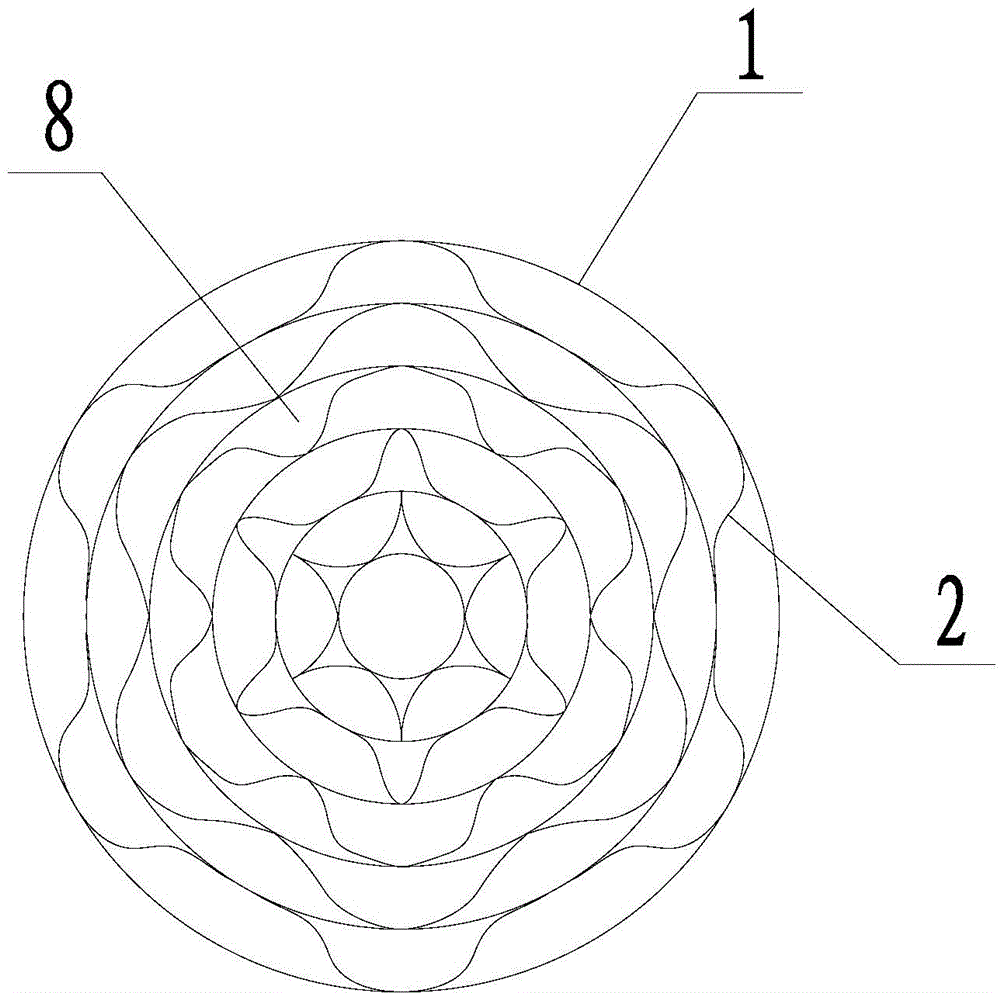

[0011] Preferred embodiments of the gas separation device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] See attached Figure 1-2 , the gas separation device of the present invention comprises a rectification tower 1, a filler 2 filled in the rectification tower 1, a gas inlet 3 and a liquid outlet 4 are provided at the bottom of the rectification tower 1, and a gas inlet 3 and a liquid outlet 4 are arranged at the top of the rectification tower 1. Cold source 6, gas outlet 7. Among them, the filler 2 penetrates up and down, so that the gas and liquid can flow up and down along the penetration direction of the filler. The cross section of the filler 2 is composed of a plurality of interconnected filler lattices. As a preferred solution, the cross section of the filler 2 is a plurality of concentric Circle, between two adjacent concentric circles is divided into multiple disconnected packing grids through wavy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com