Metal wire manufacturing method and metal wire isolating method

A manufacturing method and metal wire technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting computing speed and large parasitic capacitance, so as to increase computing speed, improve parasitic capacitance, and reduce etching rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

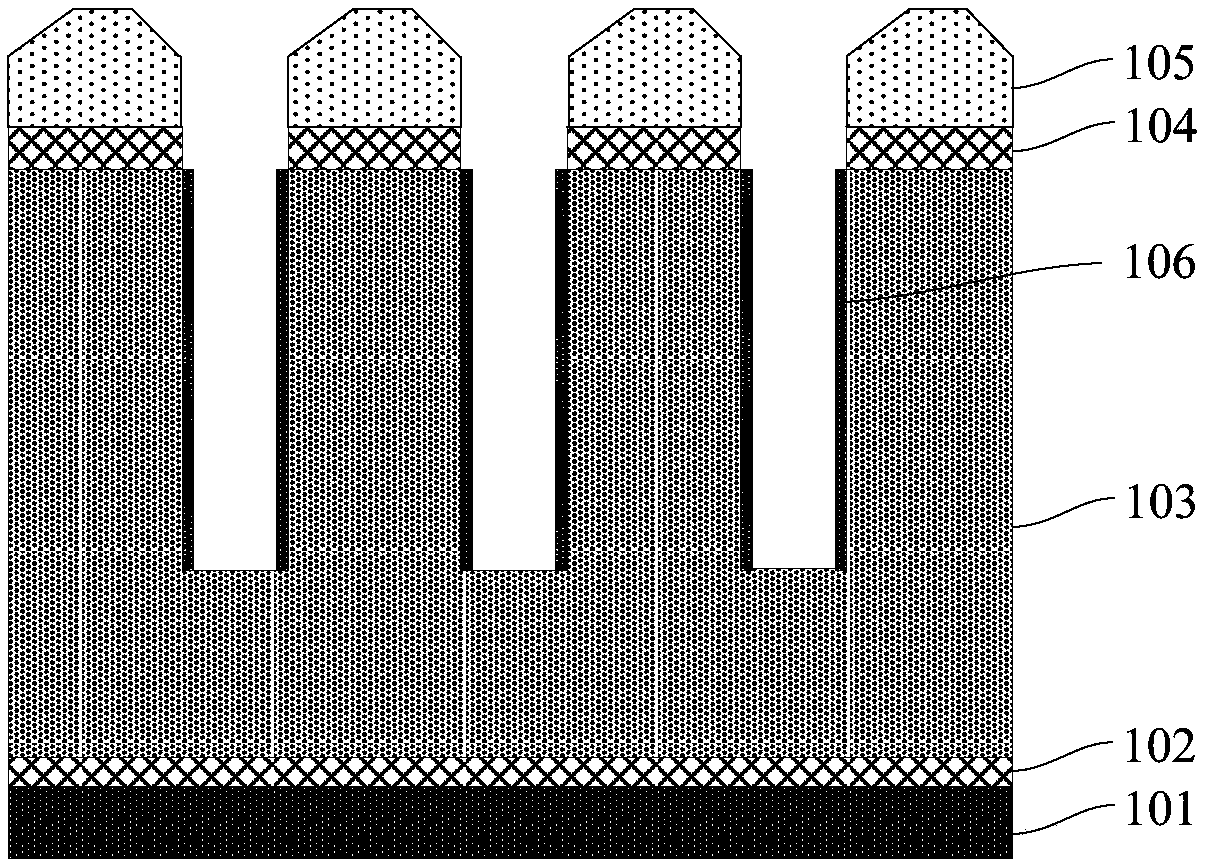

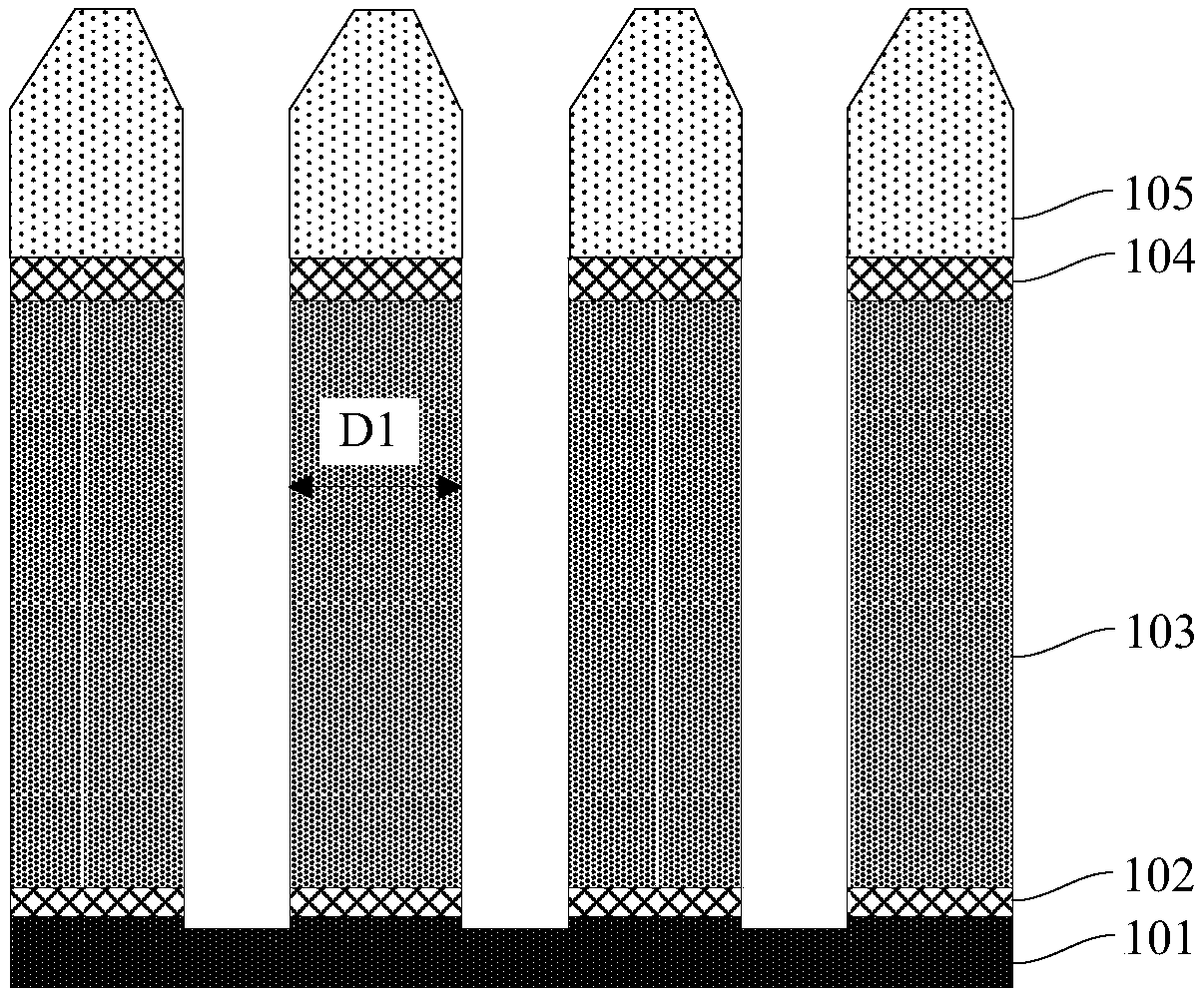

[0058] Such as Figure 8 ~ Figure 13 As shown, this embodiment provides a metal wire manufacturing method, the manufacturing method comprising:

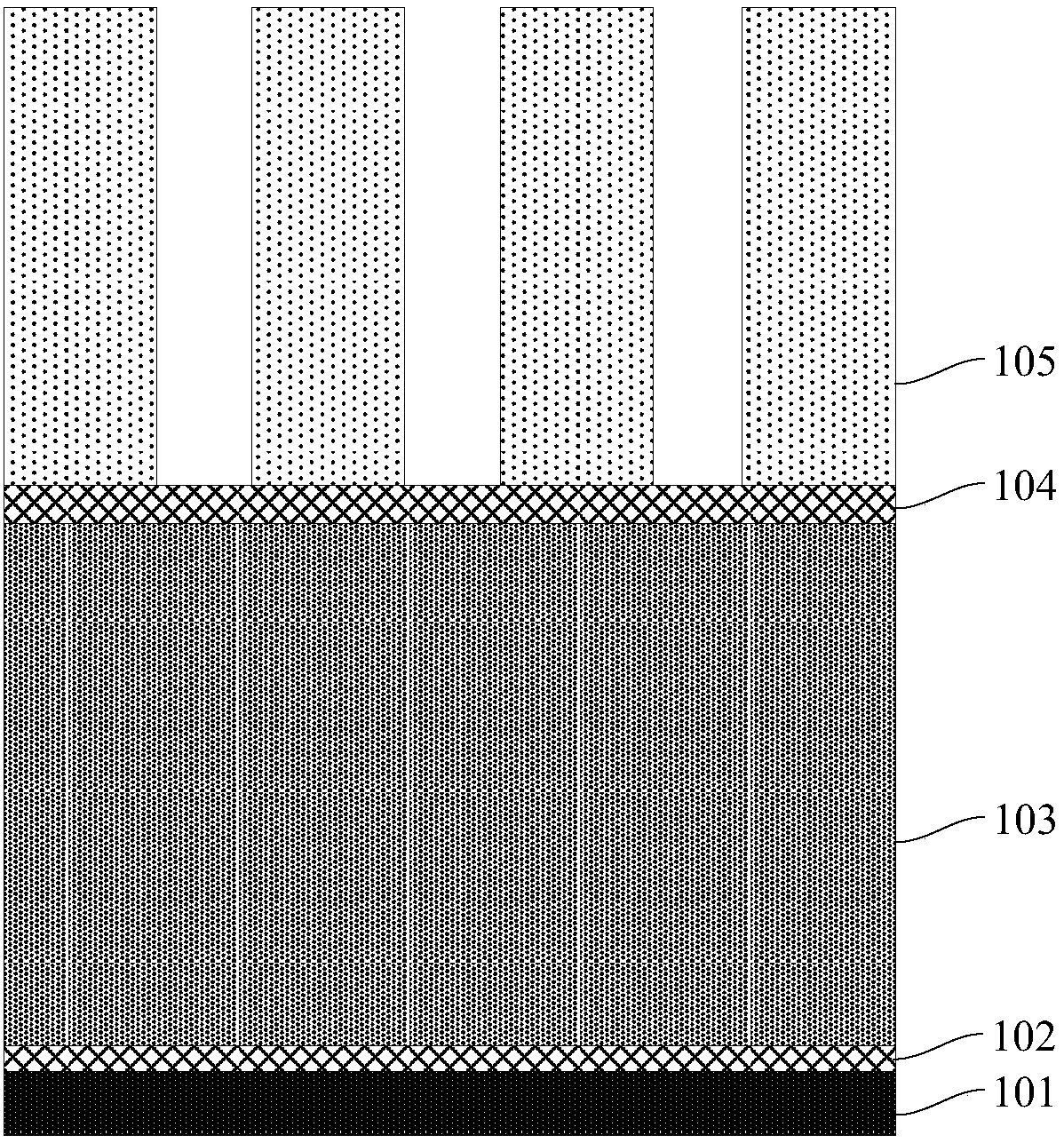

[0059] Such as Figure 8 As shown, step 1) is first performed to provide a substrate 201, which can be a silicon substrate, silicon oxide, or the like.

[0060] A titanium nitride (TiN) layer 202 is formed on the surface of the substrate 201 by a sputtering process, an evaporation process or a chemical vapor deposition process, and the titanium nitride (TiN) layer 202 can improve the connection between the subsequent metal layer 203 and the substrate. Adhesive strength of 201.

[0061] Then, a metal layer 203 is formed on the surface of the titanium nitride (TiN) layer 202 by using a sputtering process and an electroplating process, and the material of the metal layer 203 is selected from one of aluminum (Al) and aluminum-copper alloy (AlCu). A species, wherein, in the aluminum-copper alloy (AlCu), the mass ratio of copper (Cu) el...

Embodiment 2

[0073] Such as Figure 8 ~ Figure 14 As shown, the present embodiment provides a method for isolating metal lines, the method comprising:

[0074] Such as Figure 8 As shown, step 1) is first performed to provide a substrate 201, which can be a silicon substrate, silicon oxide, or the like.

[0075] A titanium nitride (TiN) layer 202 is formed on the surface of the substrate 201 by a sputtering process, an evaporation process or a chemical vapor deposition process, and the titanium nitride (TiN) layer 202 can improve the connection between the subsequent metal layer 203 and the substrate. Adhesive strength of 201.

[0076] Then, a metal layer 203 is formed on the surface of the titanium nitride (TiN) layer 202 by using a sputtering process and an electroplating process, and the material of the metal layer 203 is selected from one of aluminum (Al) and aluminum-copper alloy (AlCu). A species, wherein, in the aluminum-copper alloy (AlCu), the mass ratio of copper (Cu) element to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com