Combined multifunctional filtering device

A filtering device and multi-functional technology, which is applied in the field of composite multi-functional filtering devices, can solve the problems of increasing the head loss of the filtering system, increasing the power of the first matching water pump, and reducing the use efficiency of equipment, so as to achieve uniform fertilization, aeration and backwashing, The effect of reducing auxiliary equipment and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

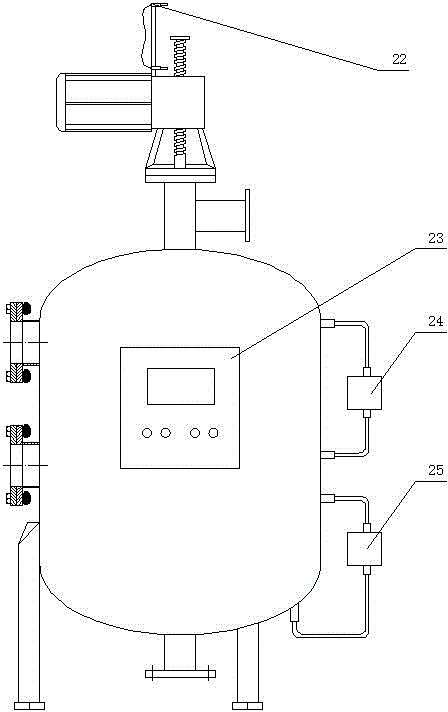

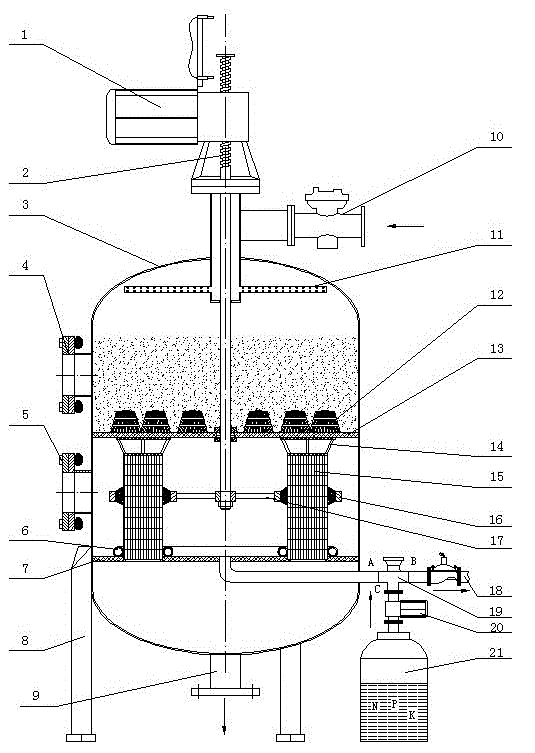

[0008] Embodiments are described in detail with reference to the accompanying drawings. A composite multifunctional filtering device, the inside of the tank body 3 is divided into upper, middle and lower layers from top to bottom, the upper layer is a sand medium filter chamber, the middle is a wedge-shaped mesh filter chamber, and the lower part is a clear water collection chamber.

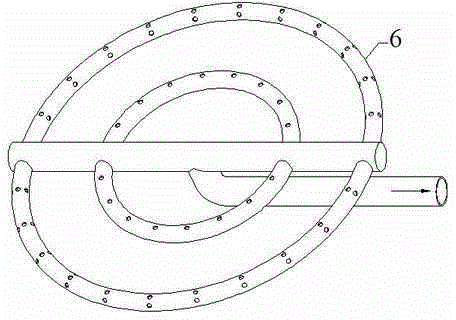

[0009] The sand medium filter cavity is set in the upper space of the upper partition 13, and the water distributor 11 is installed at the upper water inlet of the tank body 3 to disperse the incoming water as evenly as possible, so that the water containing impurities can evenly fall on the sand. The surface of the stone medium filter layer avoids stirring of the filter layer due to the concentrated impact of the water flow on the sand medium filter layer, which affects the filtering effect. The side wall of the tank body 3 is provided with a sand hole 4 . A layer of filter cap 12 is arranged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com