Automatic safety release mechanism

A decoupling mechanism and a safe technology, applied in metal processing equipment, stripping devices, manufacturing tools, etc., can solve the problem of high labor intensity of workers, and achieve the effects of compact structure, reliable action and high integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

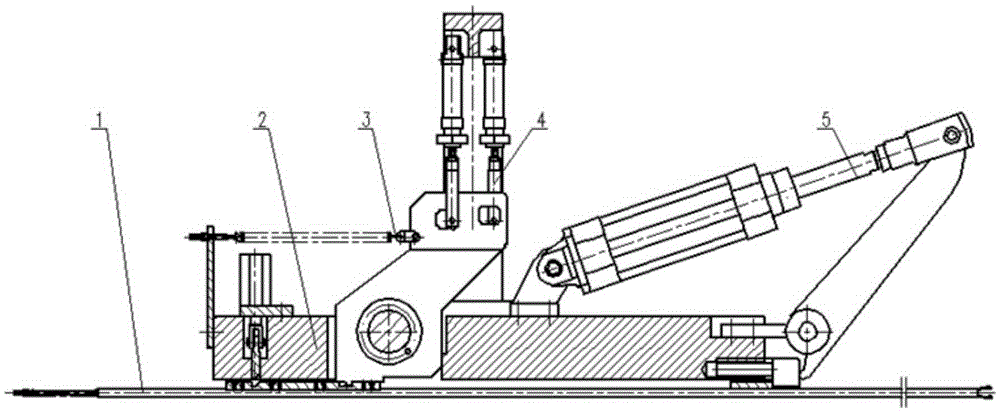

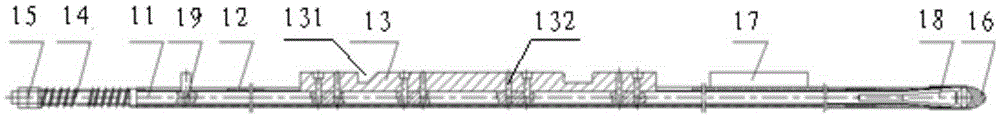

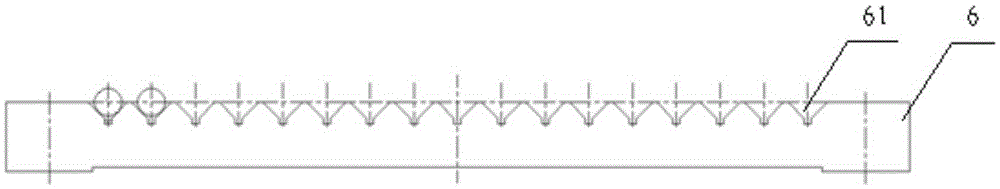

[0026] Such as figure 1 As shown, it is a schematic structural view of the automatic safety uncoupling mechanism provided by the present invention; this mechanism is suitable for the assembly process of different reactor nuclear fuel element production line components. The uncoupling device 3 rotatably arranged on the slide plate 2, the selection device 4 and the stretching device 5 arranged on the slide plate 2, and the air control system controlling the operation of the entire unhook mechanism. Among them, the number of tie rod assembly 1 is controlled by the selection device; the slide plate drives the tie rod assembly to move horizontally under the drive of the power system; the stretching device controls the head claw of the tie rod assembly to clamp the fuel rod and pull it into the grid of the fuel assembly; decou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com