Die-casting fitting conveying-separating all-in-one machine

A technology for conveying and separating and die-casting parts is applied in the field of integrated machine for conveying and separating die-casting parts, which can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

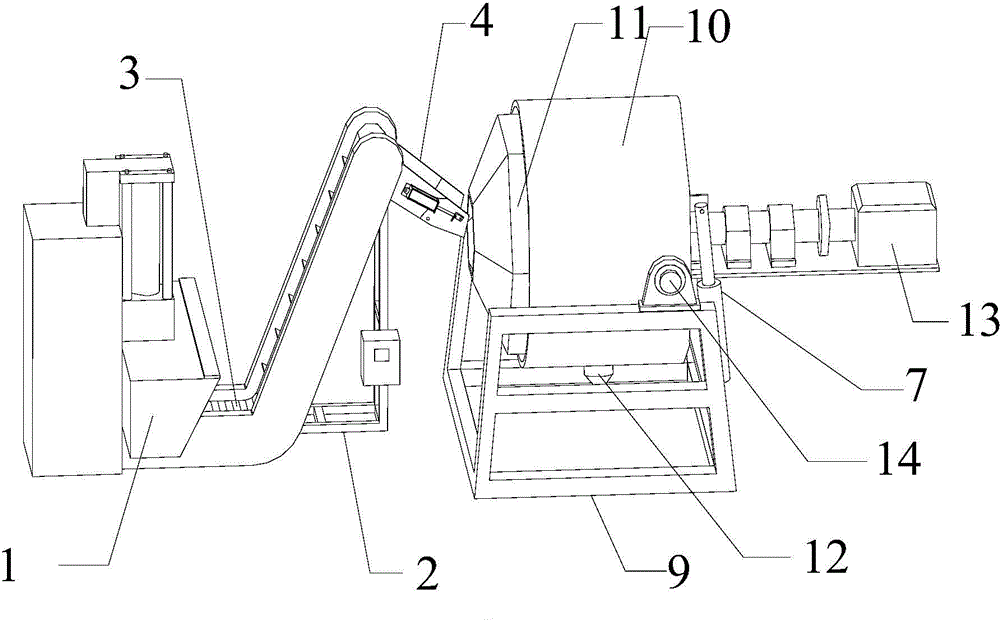

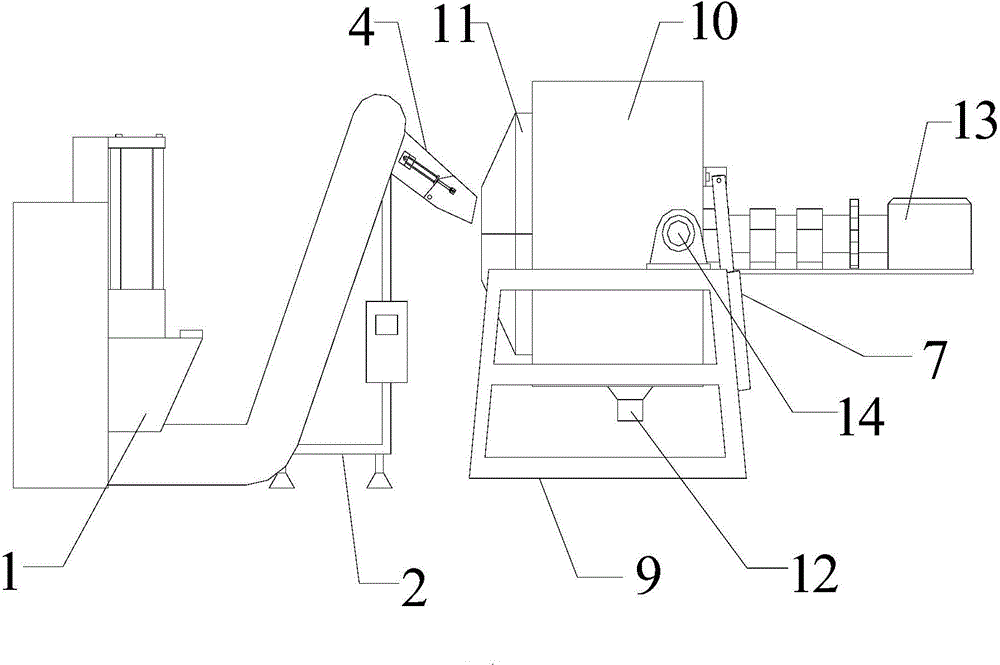

[0025] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0026] Such as Figure 1-4 As shown, a die casting conveying and separating machine includes a conveying device and a screening device;

[0027] The conveying device includes a bracket 2, on which a conveyor belt 3 is arranged. The conveyor belt 3 includes a horizontal conveying part and a lifting part. The end is connected to the lifting part, and the end of the lifting part is provided with a hopper 4 for receiving die-casting parts;

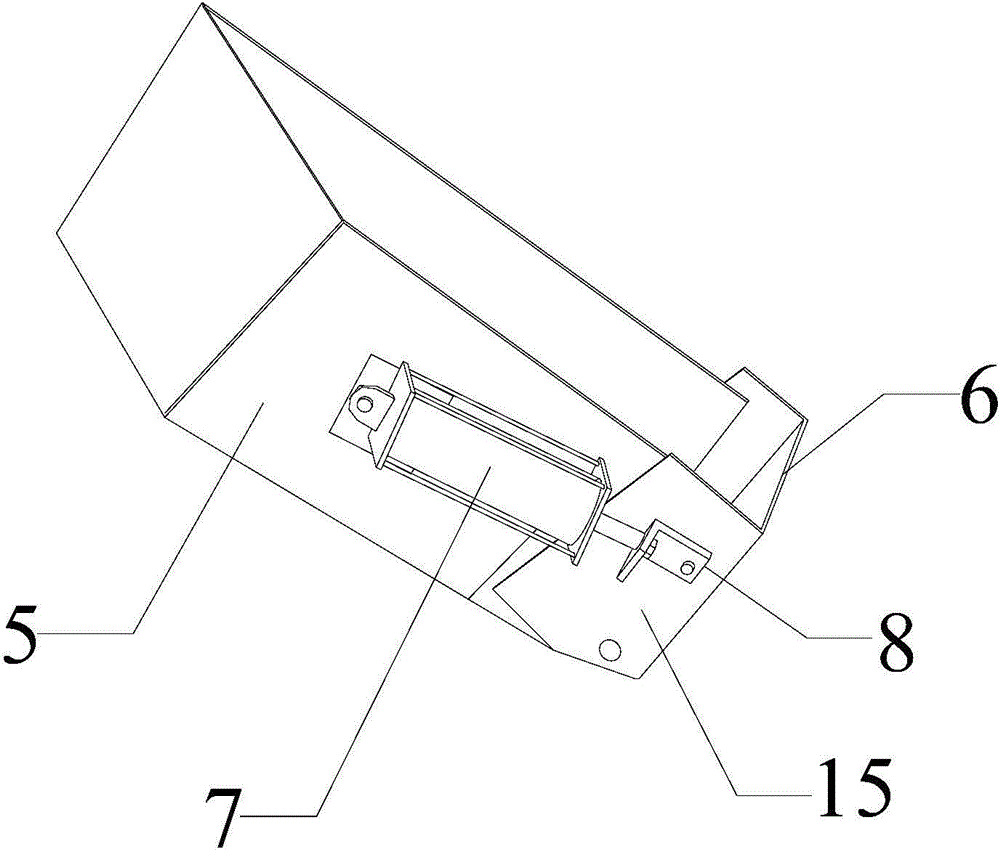

[0028] The hopper 4 comprises a bottom plate, on which two opposite side plates 5 are arranged, the ends of the two side plates 5 are provided with a front baffle 6, and the end is provided with a back baffle, and the back baffle is fixedly connected with the support 2, and the front The baffle plate 6 is rotationally connected with the side plate 5, the side plate 5 is fixedly c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap