Attitude adjustment assembly system and attitude adjustment method for docking of rocket components

An assembly system and attitude adjustment technology, applied in aircraft assembly, weapon accessories, aircraft parts, etc., can solve the problems of poor synchronization of operations, low level of equipment integration, and inability to quantify the attitude detection of sections, so as to protect the arrow body and avoid Adjust for incongruity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

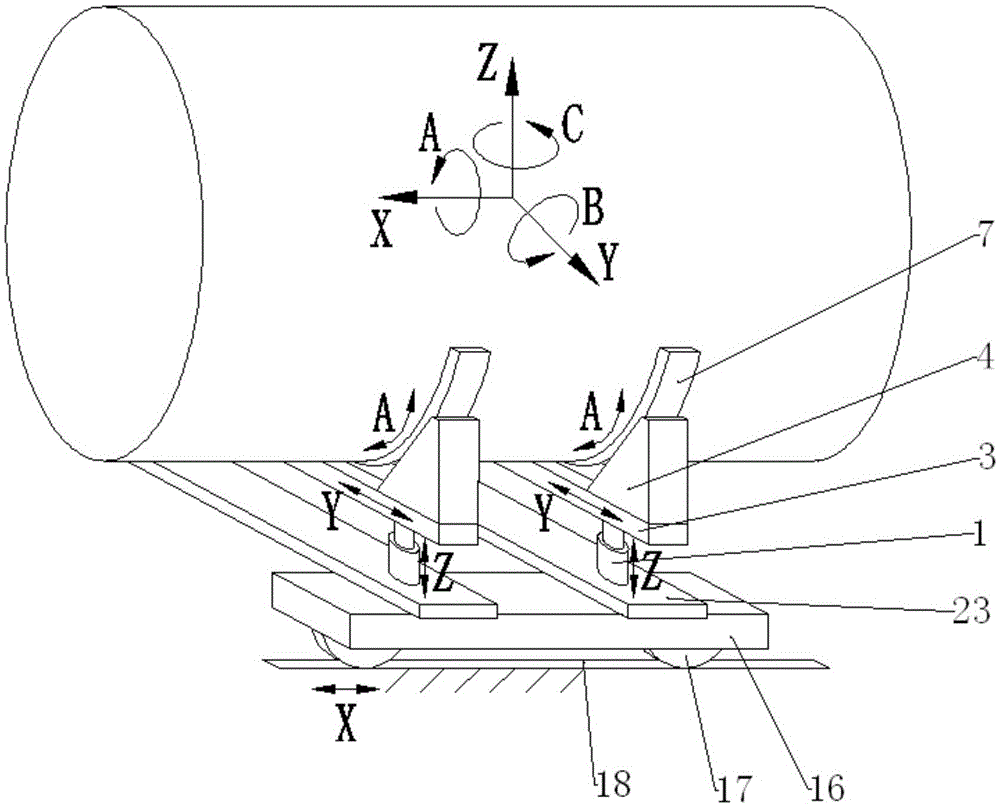

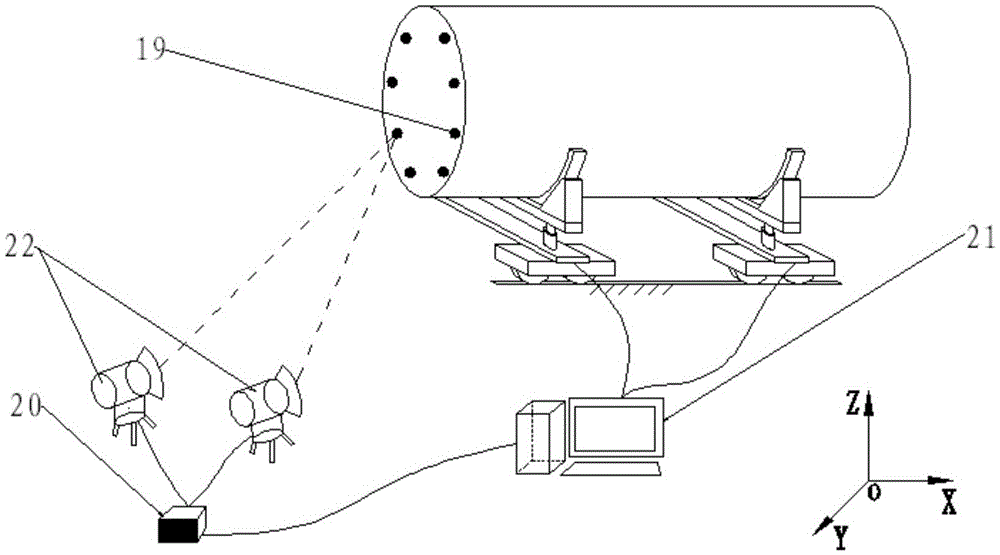

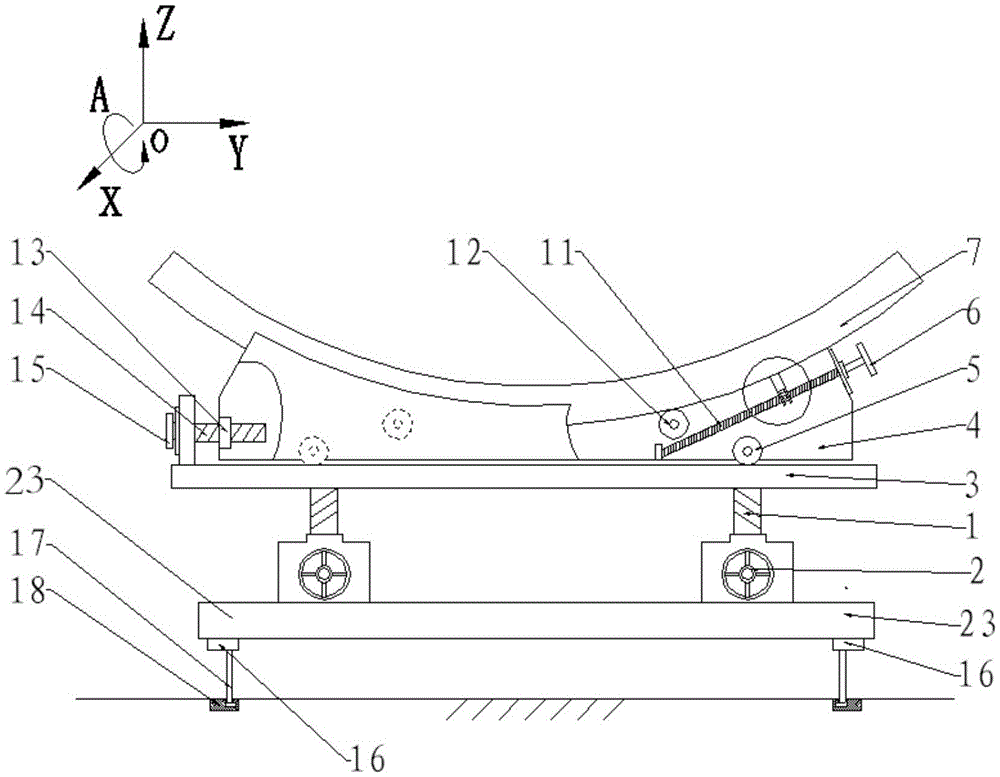

[0040] Such as figure 1 As shown, an attitude adjustment assembly system for the docking of rocket components includes an attitude adjustment system, a testing system and a controller 21. The attitude adjustment system includes two first guide rails 18 arranged in parallel, and the two first guide rails 18 The plane formed by the guide rails 18 is a horizontal plane, and each of the first guide rails 18 is provided with a plurality of crossbeams 16, and the bottom of the crossbeams 16 is provided with a guide rail wheel 17, and the guide rail wheels 17 can be driven along the first guide rail by a horizontal movement mechanism. 18 moves, and also includes two parallel attitude adjustment devices, each of which is horizontally mounted above the two first guide rails 18 and connected to the top surface of the beam, and each attitude adjustment device in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com