A Servo Positioning Structure for a Workpiece of a Centerless Grinding Machine

A centerless grinder and servo positioning technology, which is applied to machine tools, grinders, and manufacturing tools designed for grinding the rotating surface of workpieces, can solve problems such as machining errors, long time consumption, and prone to errors, and achieve accurate axial Positioning, high work efficiency, and accurate axial positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

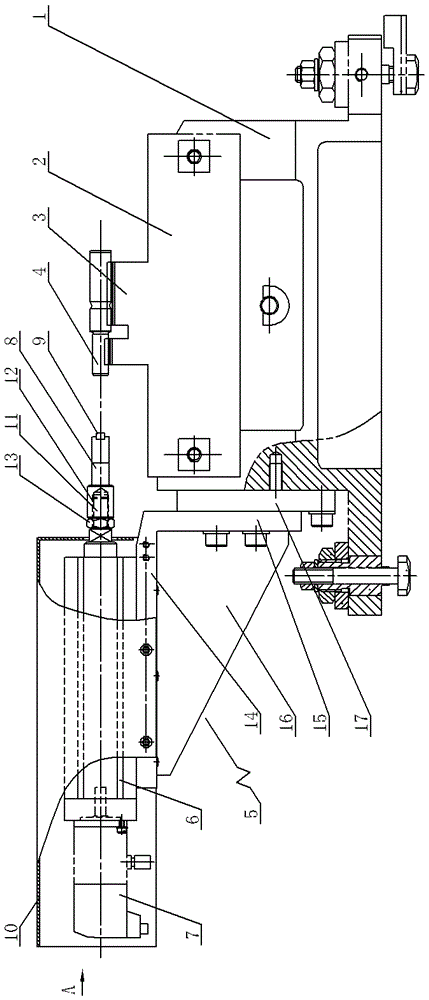

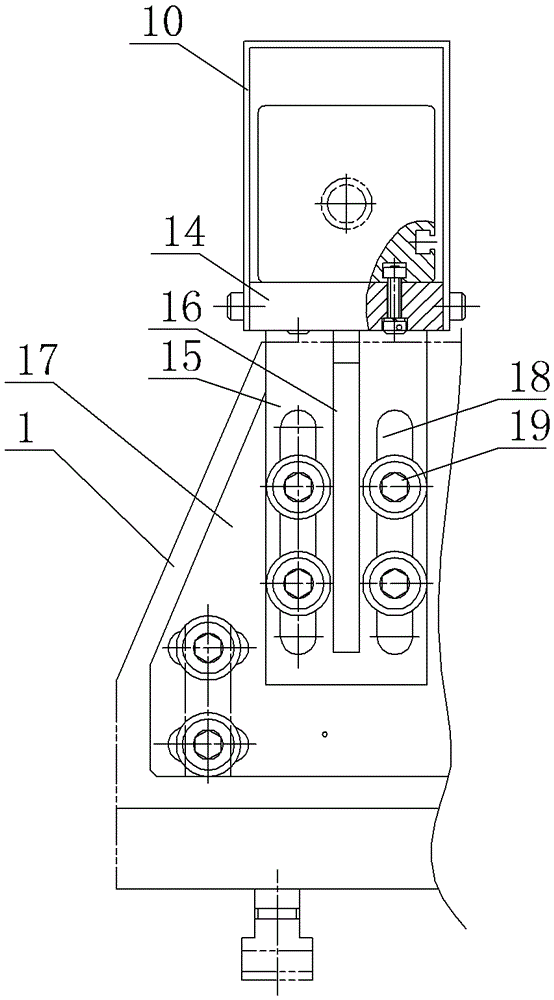

[0013] A servo positioning structure for workpieces of centerless grinding machines, see figure 1 , figure 2 : It includes a bracket 1 and a workbench 2, the workbench 2 is supported on the bracket 1, the upper end surface of the workbench 2 is a working chamber 3, the workpiece 4 is supported in the working chamber 3, and the axial front end of the bracket 1 is fastened with The bracket structure 5, the upper horizontal end of the bracket structure 5 protrudes forward from the axial front end of the bracket 1, the electric actuator 6 is supported on the upper end surface of the upper horizontal end of the bracket structure 5, and the end of the electric actuator 6 facing the working chamber 3 is The output end, the end away from the working chamber 3 is the input end, the output end of the servo motor 7 is connected to the input end of the electric actuator 6, the output end of the electric actuator 6 is fastened to the non-positioning end of the positioning block 8, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com