Ultra-large type crawler crane wheel set type bearing trolley device

A technology of crawler cranes and supporting trolleys, which is applied in the direction of cranes, etc., can solve the problems of inability to meet the design requirements of larger-scale cranes, crane tonnage level restrictions, and limited bolt diameters, etc., to achieve significant buffering effects, strong lateral stability support, The effect of improving the anti-overturning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

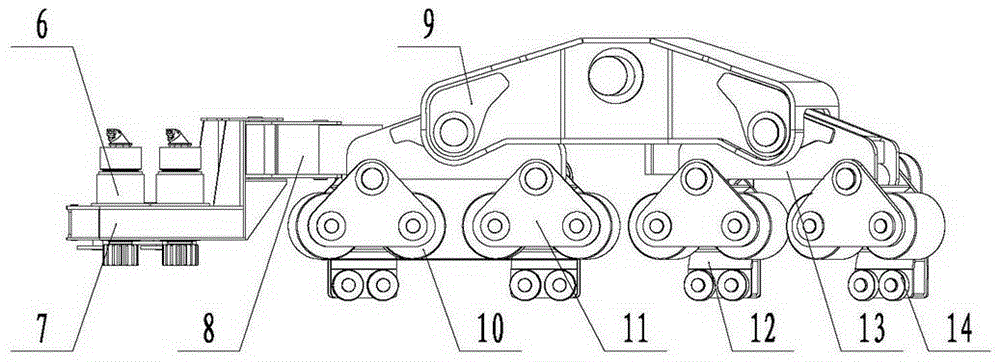

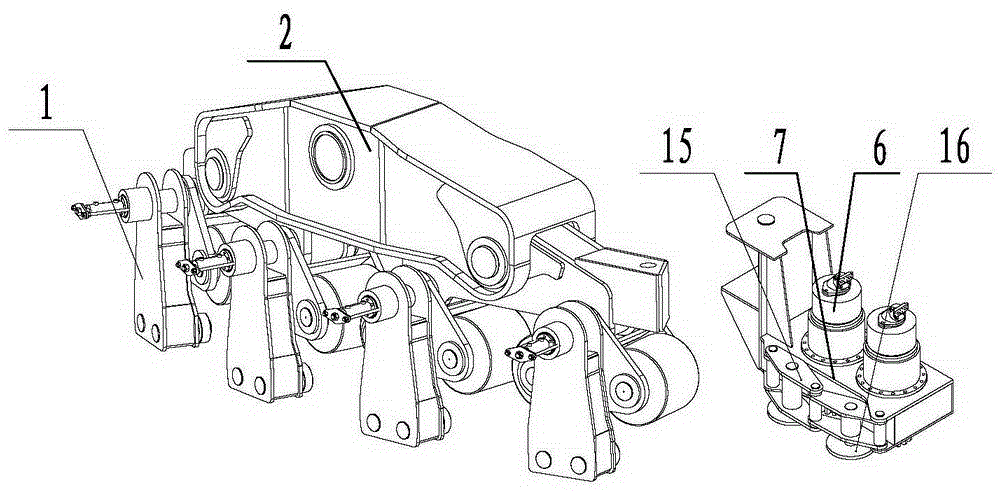

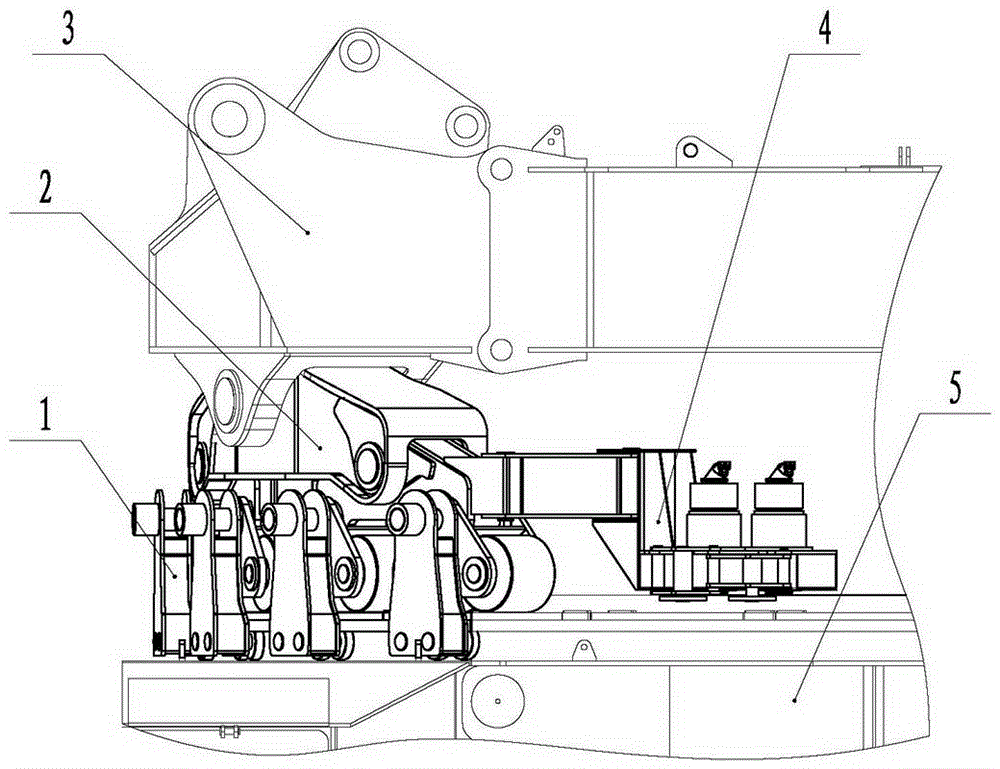

[0014] The wheel-set supporting trolley device of the super large crawler crane includes a combined trolley mechanism 2, a driving mechanism 4 and a hook roller mechanism 1. The combined trolley mechanism 2 is composed of a multi-stage beam frame hinged step by step and a wheel set 10 at the bottom. The driving mechanism 4 and The hook roller mechanism 1 is respectively connected to the combined trolley mechanism 2; the wheel set 10 at the lower part of the trolley device is adapted to the circular track 17 on the lowering base 5, and the upper part of the trolley device is connected and fixed to the upper platform 3 to form a support. The combined trolley mechanism 2 is hinged on the two ends of the first-level beam frame 9 with two second-level beam frames 13 respectively, and the two ends of the second-level beam frame 13 are hinged with two third-level beam frames 11 respectively, and each three-level beam frame 11 There are two wheels below, and the eight wheels under the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com