Needle plate convenient for replacement of carding needles

A technology that facilitates replacement and combing of needles. It is used in deburring devices, textile and papermaking, and fiber processing. It can solve problems such as needle blockage, increase production costs, and needle folding, and achieve long service life, reliable connection, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

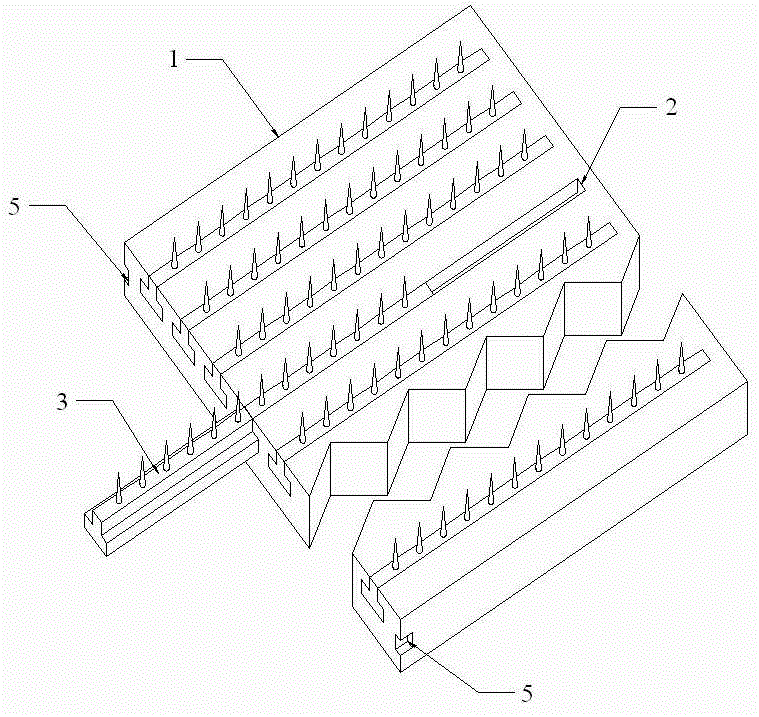

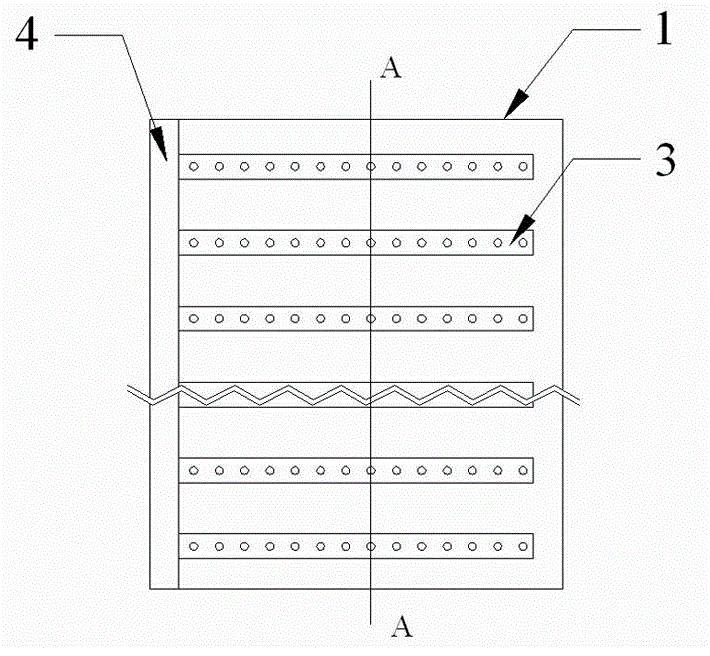

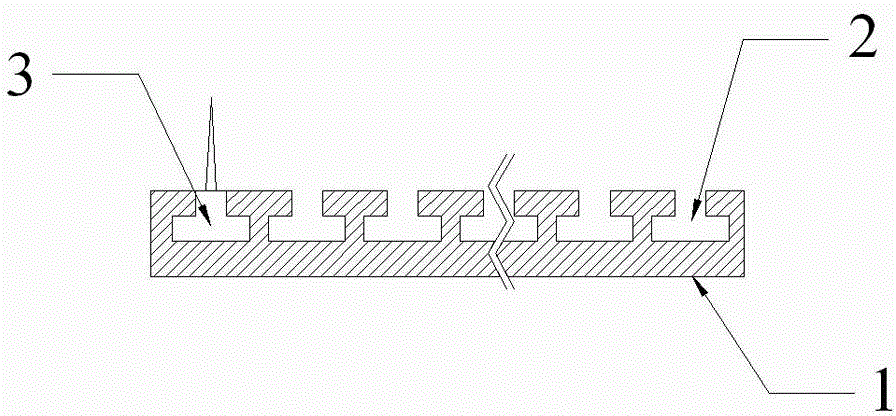

[0018] In order to show the installation diagram of the pin row 3 and the groove 2 of the present invention, figure 1 The fixed plate 4 is not shown in the figure. like figure 1 , figure 2 The illustrated needle plate for convenient replacement of comb needles includes: a base plate 1, a plurality of grooves 2, a needle row 3, and a fixing plate 4. The pin row 3 is a strip-shaped mounting block provided with comb needles. The groove 2 is located on the upper surface of the bottom plate 1 , the groove 2 is a long groove, the pin row 3 is detachably located in the groove 2 , and the fixing plate 4 is detachably located on one side of the bottom plate 1 . One end of the groove 2 is located on one side of the bottom plate 1, that is, an opening is formed on this side, and the other end of the groove 2 is located inside the bottom plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com