Segmental assembled concrete frame pier system with self-reset function and method

A concrete and self-resetting technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve problems affecting normal use, large damage residual displacement in plastic hinge areas, not an anti-seismic strategy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

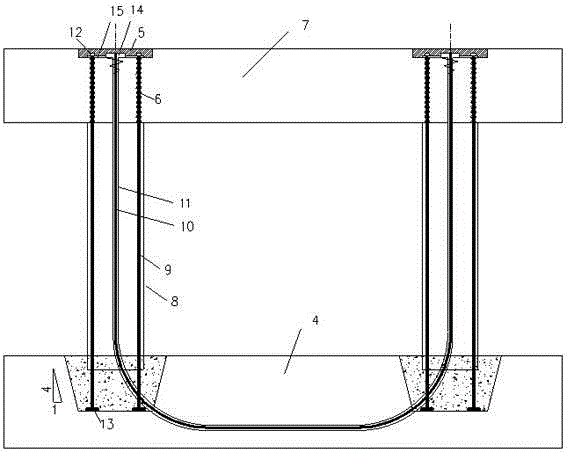

[0024] Such as figure 1 As shown, a segmentally assembled prestressed concrete frame pier system with self-resetting ability includes concrete pier 8, prefabricated concrete cover beam 7, concrete cap 4, beam end anchorage 5, steel bellows 6, and longitudinal steel bar 9 , Prestressed steel hinge line 10, prestressed steel hinge line corrugated pipe 11, pier head steel bar 13, prestressed anchorage 14, steel backing plate 15.

[0025] The two ends of the longitudinal steel bar 9 respectively pass through the two ends of the concrete pier 8 and are fixedly connected with the precast concrete cap beam 7 and the concrete cap 4 . The longitudinal steel bars 9 passing through the pipes of the concrete pier 8 pass through the steel bellows 6 in the precast concrete cover beam 4 and are fixedly connected with the steel backing plate 15 on the precast concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com