Actively-regenerative tail gas aftertreatment system and active regeneration method thereof

A tail gas after-treatment and active regeneration technology, which is applied in the electronic control of exhaust treatment devices, exhaust treatment, exhaust devices, etc., can solve problems such as difficulty in reaching DOC light-off temperature, POC loss of function, DOC poisoning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In different drawings, the same or similar parts are indicated by the same reference numerals.

[0021] It should be understood that the drawings are only used to illustrate the present invention, and the dimensions, proportions and numbers of the components are not intended to limit the present invention.

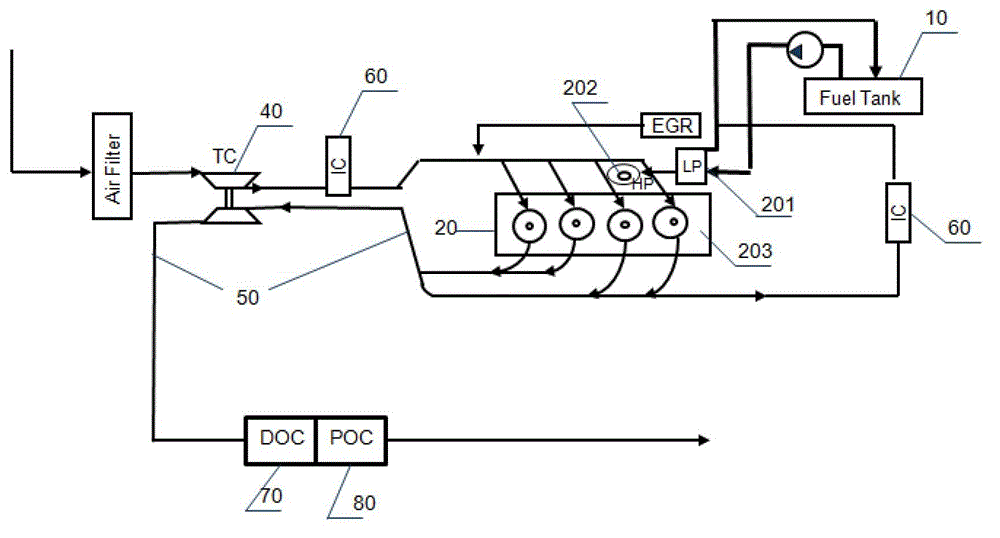

[0022] The tail gas post-treatment system of the present invention is used for post-treatment of diesel engine tail gas. After combustion in the combustion chamber of the diesel engine, waste gas will be discharged through the exhaust pipe. The main components of the waste gas are C, HC, CO, NO and SO2. Through the exhaust pipe, the exhaust gas enters the diesel oxidation catalyst (Diesel Oxidization Catalyst, DOC) for treatment. DOC includes DOC carrier and catalyst. The carrier of DOC is divided into ceramics and metals. Usually the ceramics are cordierite, and there are many types of metals, such as iron, copper, and brass. And this catalyst is generally preciou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com