Device and method for regenerating exhaust purification catalyst

An exhaust purification and regeneration device technology, applied in catalyst regeneration/reactivation, exhaust devices, physical/chemical process catalysts, etc. The effect of good regeneration efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

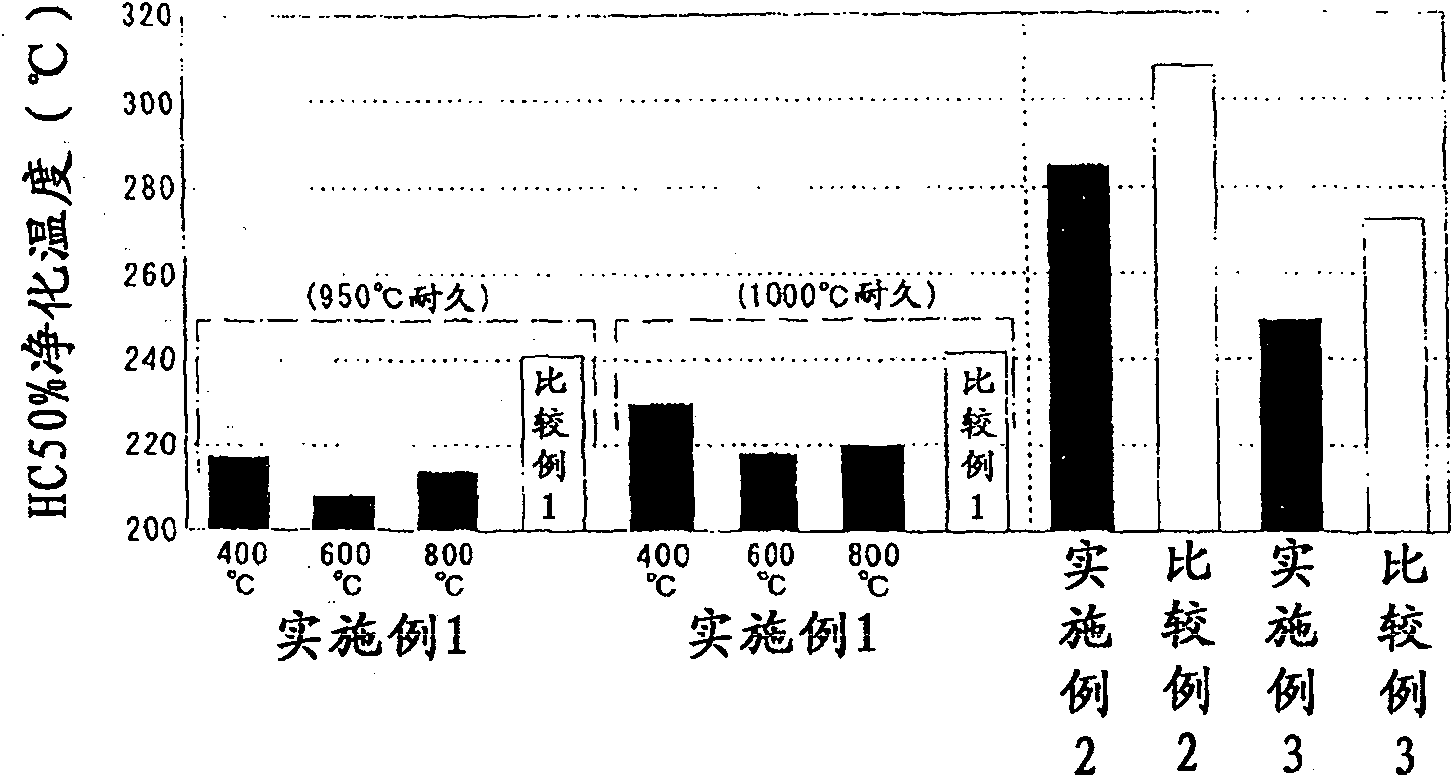

[0052] The above-mentioned granular catalysts were placed in a tubular furnace, and subjected to a nitrogen endurance test in which they were held at 950° C. and 1000° C. for 5 hours in a nitrogen atmosphere. Each catalyst after the nitrogen durability test was subjected to an oxidation step of holding in air at 400° C., 600° C., and 800° C. for 2 hours, and then, each catalyst after the oxidation step was subjected to an oxidation step containing 3% by volume of H 2 The reduction step was carried out at 500° C. for 15 minutes in a nitrogen atmosphere.

Embodiment 2

[0056] Put the above-mentioned granular catalyst into the tubular furnace, and carry out the process in rich gas (CO: 2%, N 2 : remainder) and lean gas (O 2 : 5%, N 2 : Remainder) RL endurance test of holding at 1000° C. for 5 hours in an atmosphere alternately repeated every 120 seconds. The catalyst after the RL endurance test was subjected to an oxidation step of holding in air at 600° C. for 2 hours, and then, the catalyst after the oxidation step was subjected to an oxidation step containing 3% by volume of H 2 The reduction step was carried out at 500° C. for 15 minutes in a nitrogen atmosphere.

Embodiment 3

[0060] The above-mentioned granular catalyst was placed in an electric furnace, and an air durability test was performed in which the catalyst was kept in air at 1000° C. for 5 hours. The catalyst after the air durability test was subjected to an oxidation step of holding in air at 600° C. for 2 hours, and then, the catalyst after the oxidation step was subjected to an oxidation step containing 3% by volume of H 2 The reduction step was carried out at 500° C. for 15 minutes in a nitrogen atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com