Anti-corrosion and anti-blocking self-cleaning vertical tubular air preheater

An air preheater, self-cleaning technology, used in the removal of solid residues, lighting and heating equipment, combustion product treatment, etc. , to achieve the effect of facilitating large-scale promotion and use, saving energy consumption and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

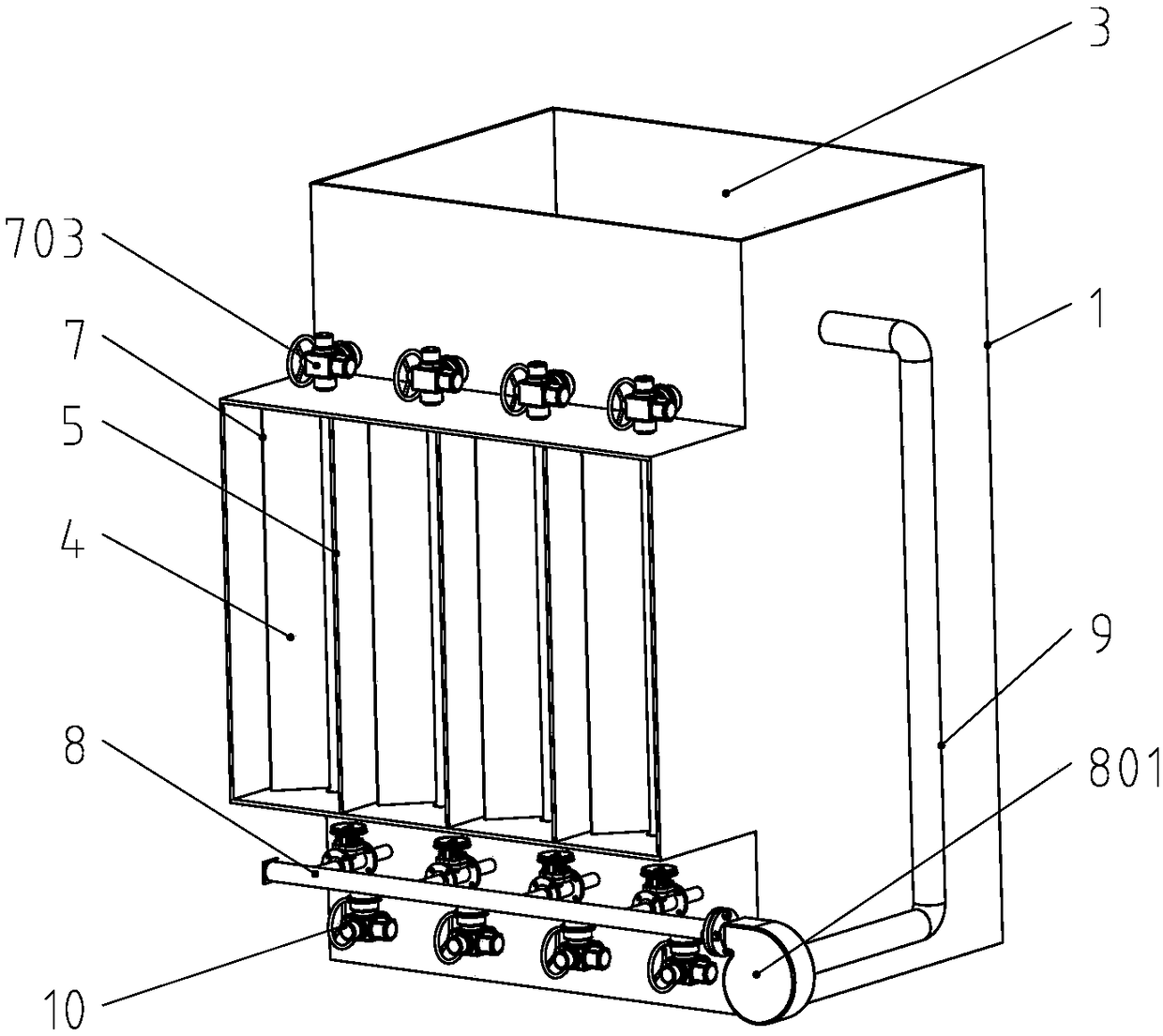

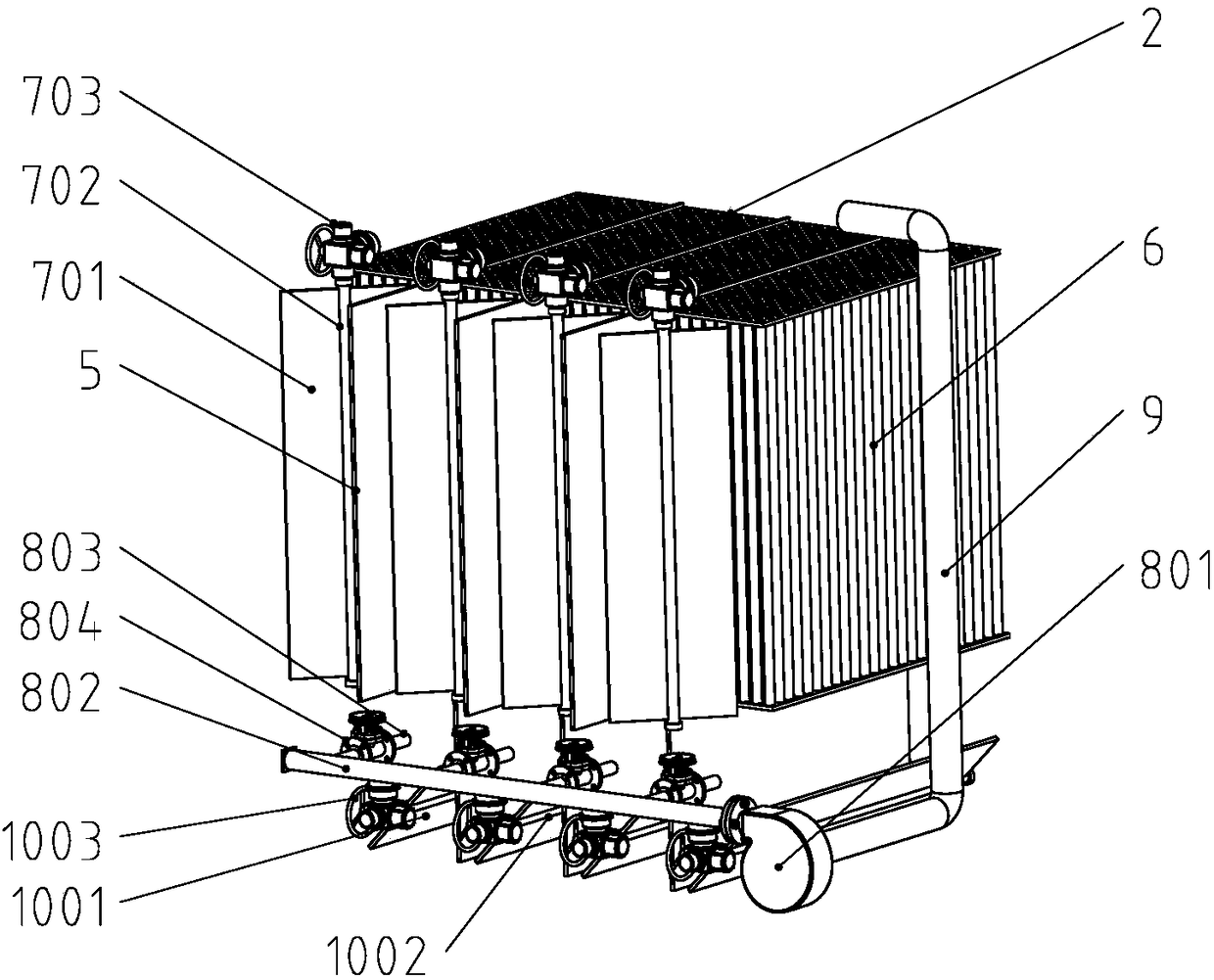

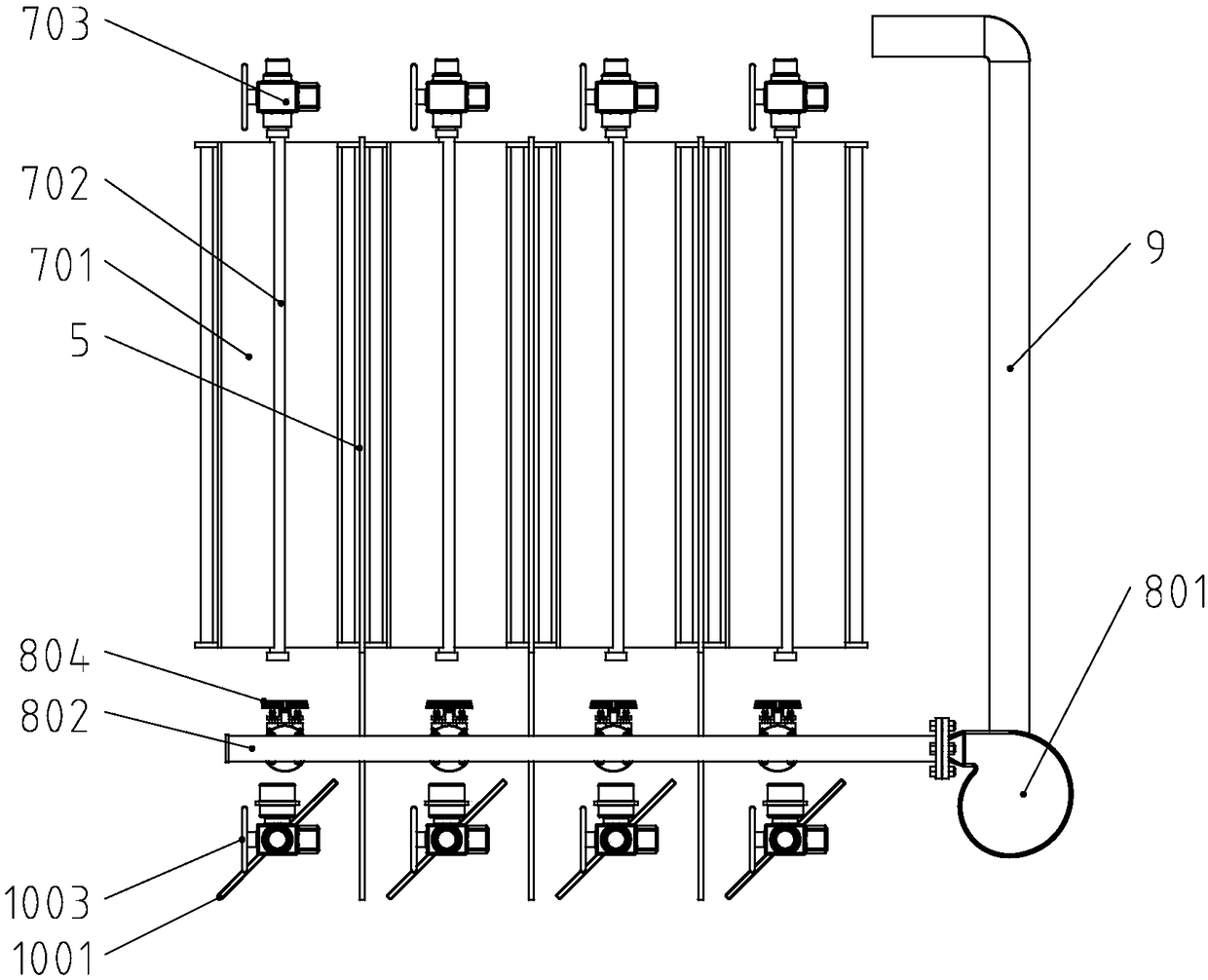

[0025] Such as Figure 1~3 The anti-corrosion, anti-blocking and self-cleaning vertical tubular air preheater shown includes an air preheater box 1 and four preheating modules 2, and the air preheater box 1 is provided with high-temperature flue gas for heat exchange. The gas channel 3 and the air channel 4, the high-temperature flue gas channel 3 and the air channel 4 are perpendicular to each other, and four preheating modules 2 are arranged side by side in the air preheater box 1, and an air preheater is arranged between adjacent preheating modules 2 Each preheating module 2 includes a number of high-temperature flue gas pipes 6 arranged in parallel along the high-temperature flue gas passage 3 .

[0026] The air preheater box 1 is provided with multiple air barriers 7 at the inlet of the air channel 4 , and each air barrier 7 corresponds to a preheating module 2 . The air preheater box 1 is provided with a flue gas recovery device 8 at the exit of the high-temperature flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com