High-resistance permanent magnet synchronous motor

A permanent magnet synchronous and motor technology, which is applied to synchronous machine parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc. problems, to achieve the effect of increasing the starting delay time, improving the starting efficiency, and reducing the surge impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

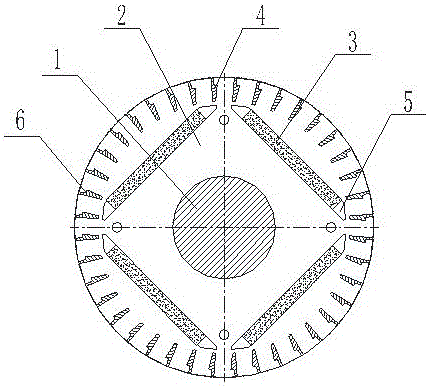

[0015] The motor includes a closed motor casing, a stator, a rotor, a high-resistance rotor winding and a permanent magnet. Overcome the shortcomings of hoisting motors that are not suitable for continuous operation and poor energy saving efficiency.

Embodiment 2

[0017] The motor includes a closed motor casing, a stator, a rotor, an internal air-cooled fan blade, a high-resistance rotor winding and a permanent magnet. There is a flow channel for air circulation in the closed motor casing, which is also based on the high-resistance rotor winding of the lifting motor. , to overcome the shortcomings of high-efficiency permanent magnet synchronous motors with small starting torque; to overcome the shortcomings of lifting motors that are not suitable for continuous operation and poor energy-saving efficiency with a permanent magnet structure. In order to overcome the working condition that the equipment can only enter the continuous operation state after multiple starts in a short period of time, the air circulation channel and the internal air cooling blades in the closed motor shell are used to achieve the internal air passing through the motor at one end. The passage in the shell enters, and then presses out from the other end, and then e...

Embodiment 3

[0019] The motor includes an open motor casing, a stator, a rotor, an additional fan, a high-resistance rotor winding and a permanent magnet. It is also based on the high-resistance rotor winding of the lifting motor to overcome the small starting torque of the high-efficiency permanent magnet synchronous motor. Disadvantages: The permanent magnet structure overcomes the shortcomings of the hoisting motor not suitable for continuous operation and poor energy saving efficiency. In order to overcome the working condition that some equipment needs to be started many times in a short period of time before entering the continuous operation state, in the surrounding dust-free environment, the open motor casing and its fan are used to form an external air forced The high-efficiency heat exchange of the cooling gives the motor a more efficient cooling effect, thereby avoiding the demagnetization of the permanent magnet caused by the temperature rise of continuous starting.

[0020] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com