A Multi-functional Orbital Weld Seam Flaw Detection Scanner

A track, a pair of technology, applied in the field of multi-functional track weld flaw detection scanner, can solve the problems of inaccurate positioning, insufficient power, large screw rod jump, etc., to reduce manufacturing costs, extend scanning time, and ensure durability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

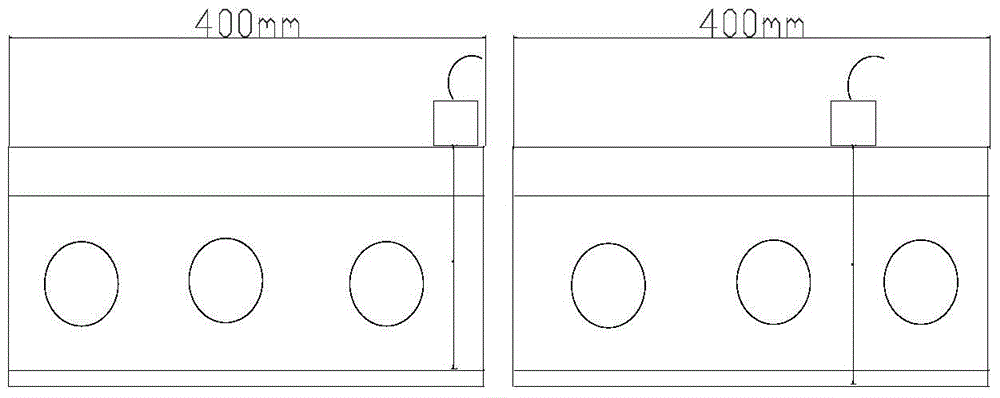

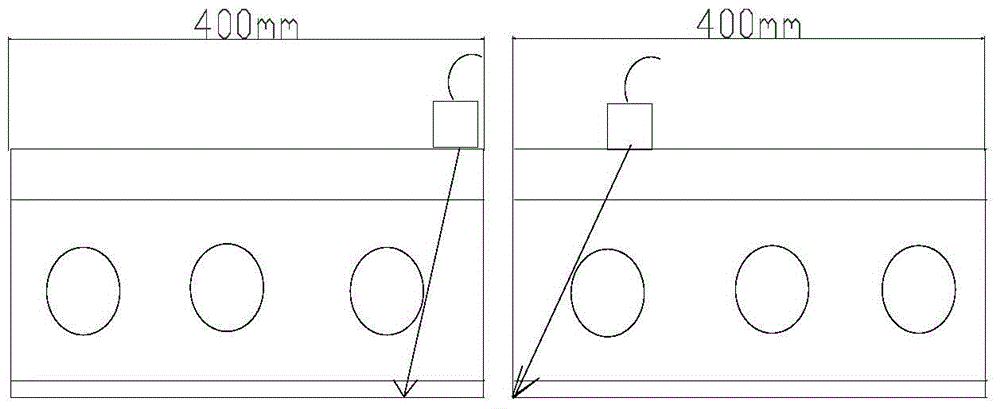

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

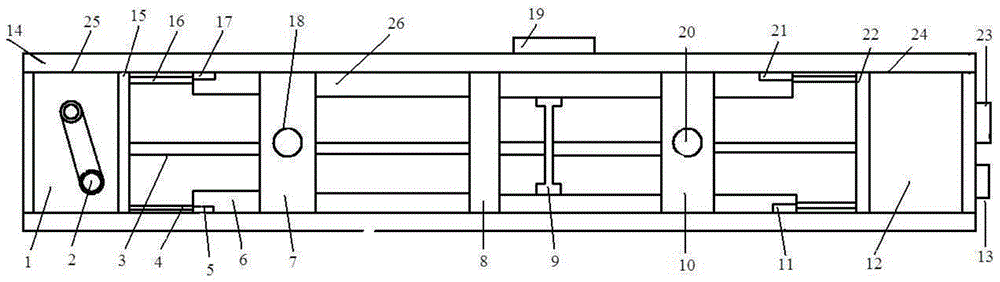

[0038] A multifunctional orbital weld flaw detection scanner, including:

[0039] a rectangular frame comprising a pair of supports 14 parallel to each other;

[0040] At least one slider 7, the slider is arranged on the upper part of the rectangular frame in a manner of sliding in a direction parallel to the support body;

[0041] At least one ultrasonic probe 18, each ultrasonic probe is arranged on a slider;

[0042] At least one pair of magnet seats 6, a pair of magnet seats are respectively arranged on opposite sides of a pair of supports, the magnet seats are made of aluminum alloy, and the magnet seats are located at the bottom of the rectangular frame; and

[0043] As for the magnet 5, a magnet is bonded on the inner surface of each magnet seat through an adhesive. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com