Pro/E-based rapid standard equipment body model building method

A ontology and model technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems that affect design efficiency and standardization, different operating methods, and many operating steps, so as to eliminate unreliable factors, Standardization and correctness assurance, the effect of reducing the amount of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

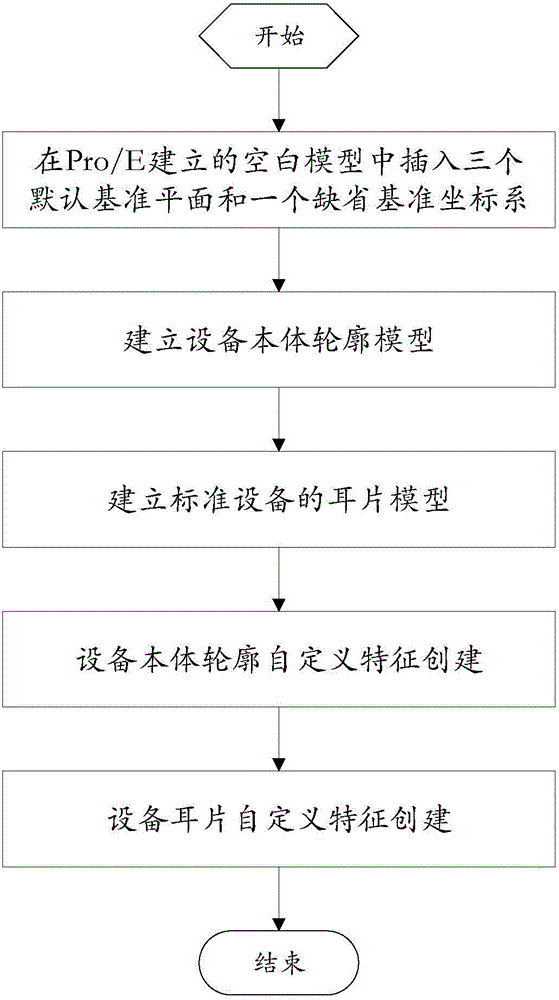

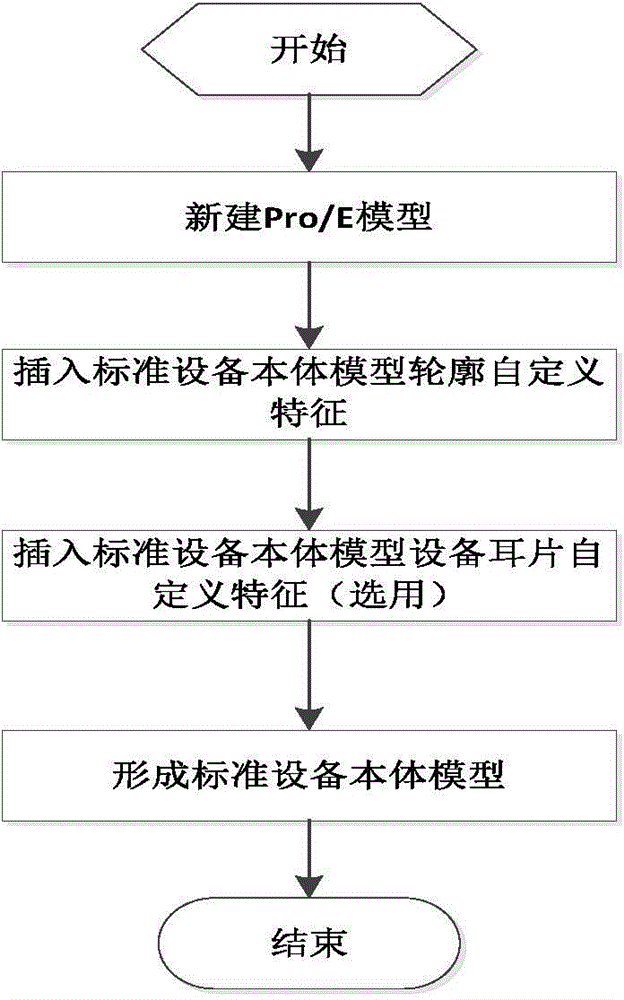

Method used

Image

Examples

Embodiment

[0070] Take the creation of a standard equipment body model including four F-shaped non-corners as an example. The equipment body is a cuboid with a length of 100cm, a width of 80cm, and a height of 60cm. There is a mounting hole on each lug, the diameter of the hole is 6cm, and the distance between the center of the hole and the contour surface of the device body is 8cm. The four lugs are symmetrical to the center of the contour of the device body, and the distance between each lug and the central symmetrical plane is 30cm. .

[0071] Open the Pro / E software and create a new part model. Execute the Pro / E operation "Insert" - "User-Defined Feature" operation, select the device body outline custom feature file from the disk, and assign 100 to the length dimension, 80 to the width dimension, and 60 to the height dimension in the Insert Custom Feature window , perform confirmation, and quickly generate the outline of the device body that meets the design requirements. At the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com