Composite wiring insulation bottle

A technology of insulating bottles and wires, applied in the direction of insulators, supporting insulators, electrical components, etc., can solve the problems of threatening the safety of circuit operators, personal safety, low work efficiency, inconvenient transportation and use, etc., to improve the impact resistance and anti-corrosion Deformability, reduced weight and production costs, and improved repair and replacement capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

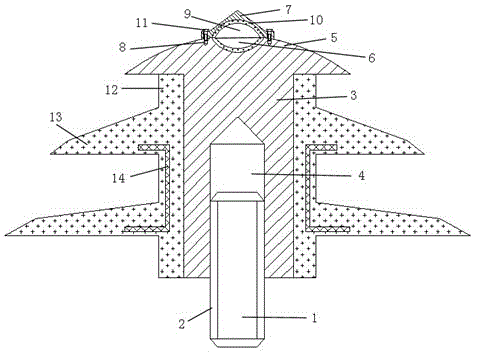

[0011] Such as figure 1 The shown composite wire insulating bottle is composed of a column 1 and an insulator, the outer side of the column 1 is provided with a connecting thread 2, and the insulator is composed of a hard insulating column 3 and an elastic insulating protective sleeve. The elastic insulating protective cover is covered on the outer surface of the hard insulating column 3, and the bottom of the hard insulating column 3 is provided with a connecting screw hole 4 along the axial direction, and the length of the connecting screw hole 4 is not greater than 1 of the length of the hard insulating column 3 / 2, the top of which is provided with a hemispherical pay-off platform 5, and the upper surface of the pay-off platform 5 is additionally provided with a wiring groove 6, a wire crimping cover 7 and connecting bolt holes 8 symmetrically distributed with the wiring groove, wherein the crimping cover 7 is under The surface is provided with a "U"-shaped wire groove 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com