Electric linear actuator

A linear actuator, electric technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of increasing the size and power consumption of electric motors, increasing power loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

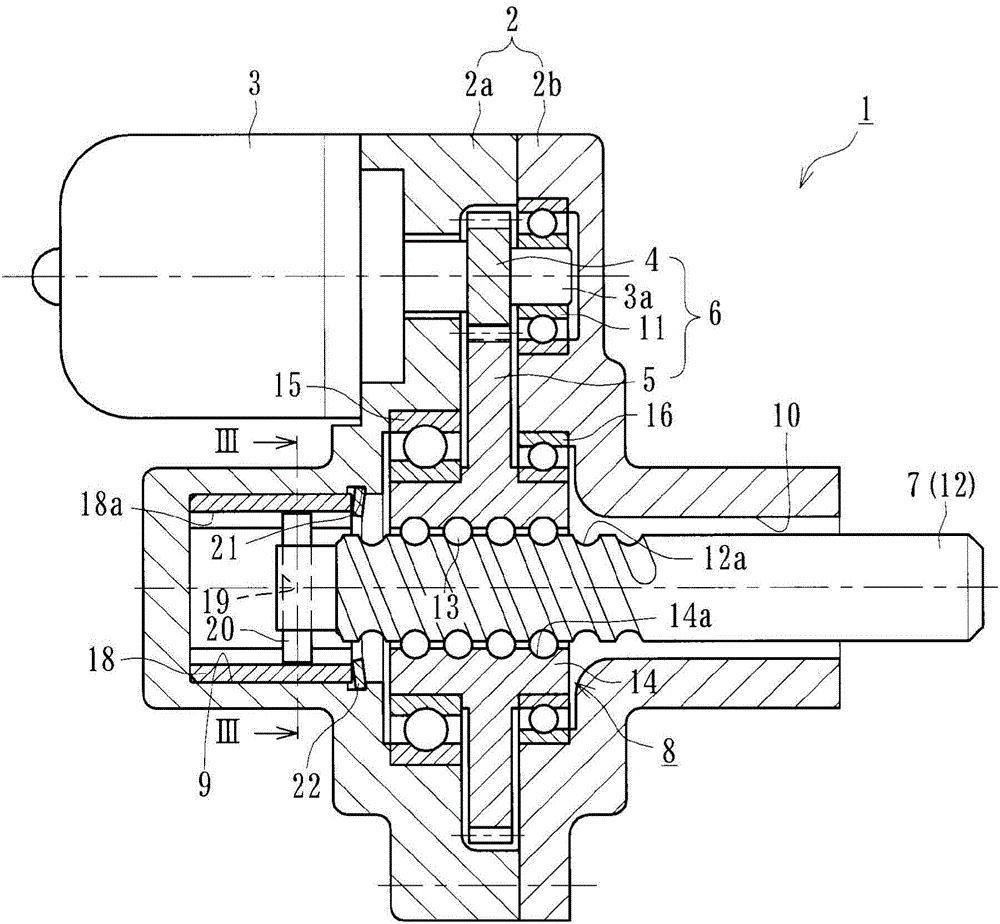

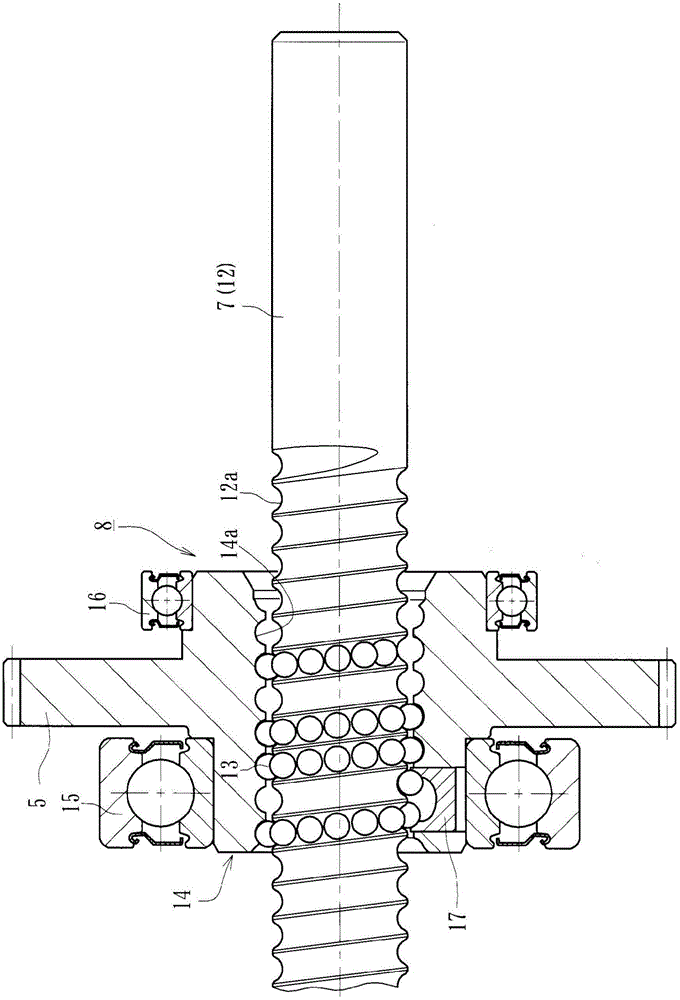

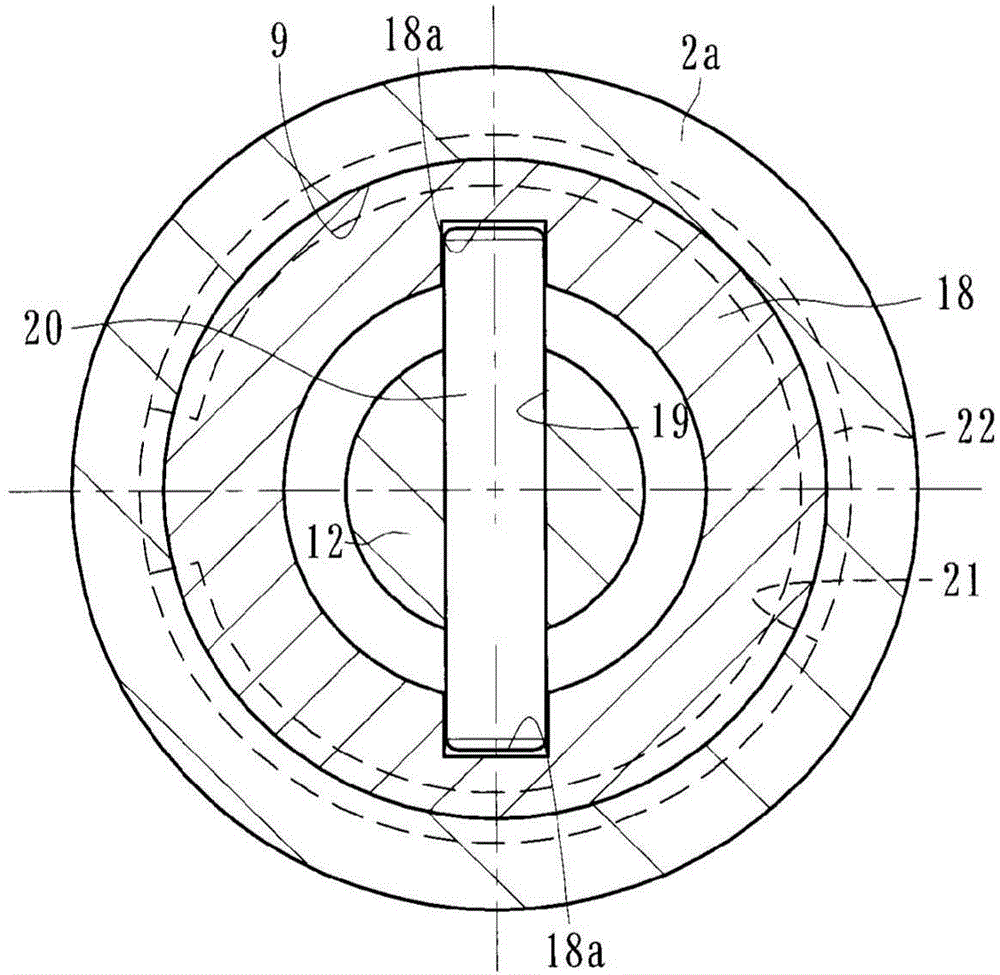

[0036] Hereinafter, a preferred embodiment of the present invention will be described with reference to the accompanying drawings.

[0037] figure 1 is a longitudinal sectional view showing a preferred embodiment of the electric linear actuator of the present invention; figure 2 is showing figure 1 Longitudinal cross-sectional view of the ball screw mechanism of the electric linear actuator; image 3 is along figure 1 The sectional view taken along the line III-III; Figure 4 is a partial enlarged view showing the mounting portion of the stop ring; Figure 5 (a) is a side view of the snap ring of the present invention, and Figure 5 (b) is Figure 5 a front view of (a); and Image 6 It is an explanatory drawing showing the attachment part of the conventional snap ring.

[0038] Such as figure 1 As shown, the electric linear actuator 1 of the present invention includes: a cylindrical housing 2, an electric motor 3 mounted on the housing 2, a reduction mechanism 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com