hydraulic breaker

A technology of hydraulic breaker and hammer shell, applied in the field of hydraulic breaker, can solve the problems of inconsistency, reduced work efficiency, insufficient pre-lifting pressure, etc., so as to reduce alignment and crushing depth adjustment operations, improve work efficiency, and improve processing efficiency. Create easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

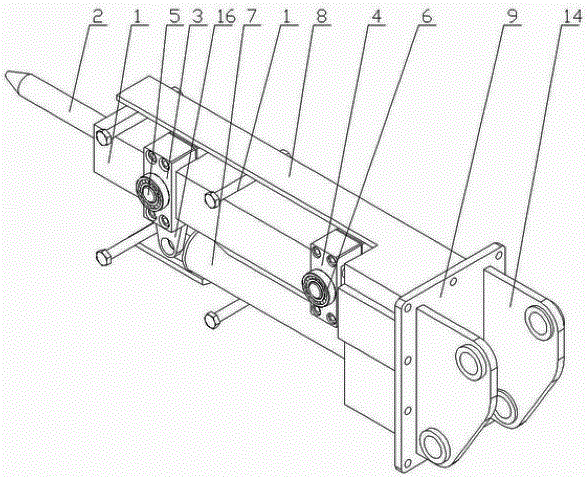

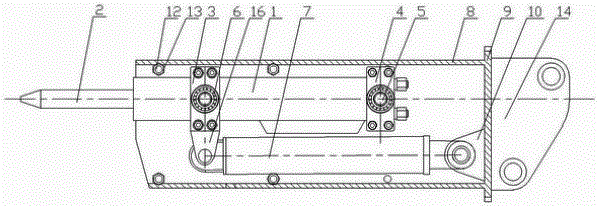

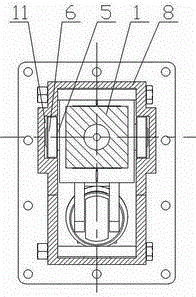

[0025] Such as figure 1 , figure 2 , image 3 as shown, figure 1 One side plate of the hammer housing 8 is removed. In the present invention, the hammer body 1 with the steel drill 2 is connected with the hammer shell 8 through a pressing device and a moving device. Under the action of the pressing device, the hammer body 1, which performs the impact crushing function, is pressed and moves forward through the moving device, and the steel drill 2 always presses against the striking point and follows up.

[0026] The front splint 3 and the rear splint 4 of the mobile device of the preferred solution of the present invention clamp the hammer body 1 by bolts, and the front splint 3 and the rear splint 4 are integrated with the hammer body 1; the outsides of the front splint 3 and the rear splint 4 are symmetrically arranged respectively There are two roller shafts 5, and roller 6 is installed on the roller shaft 5; the inner side of hammer housing 8 is provided with groove tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com