Switching method of hot-rolling recoiling machines

A coiler and hot-rolled coil technology, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as coiler stacking steel accidents, long time, affecting the fast rolling rhythm of the rolling line, etc. To achieve the effect of ensuring reliability and avoiding serious accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

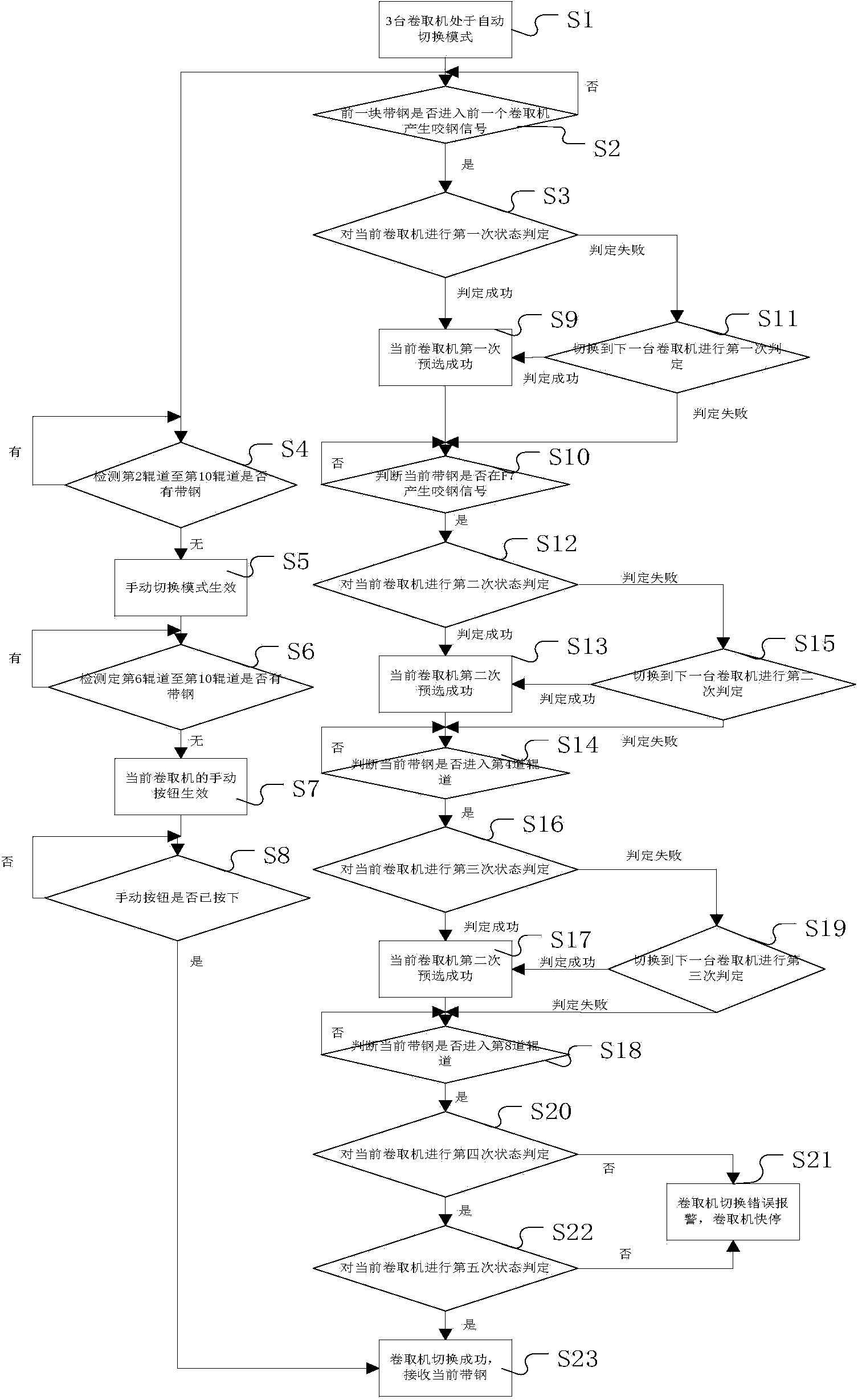

[0047] In the embodiment of the present invention, a hot-rolling coiler switching method is described, which is used to switch between three coilers, wherein the three coilers are respectively: coiler 1, coiler 2. Coiler 3.

[0048] The present invention aims to ensure the reliability of the coiler switching by performing five state judgments on the currently selected coiler for the strip steel, and to provide guarantee for the subsequent coiling process, completely avoiding the failure of the coiler to pile up steel. serious accident.

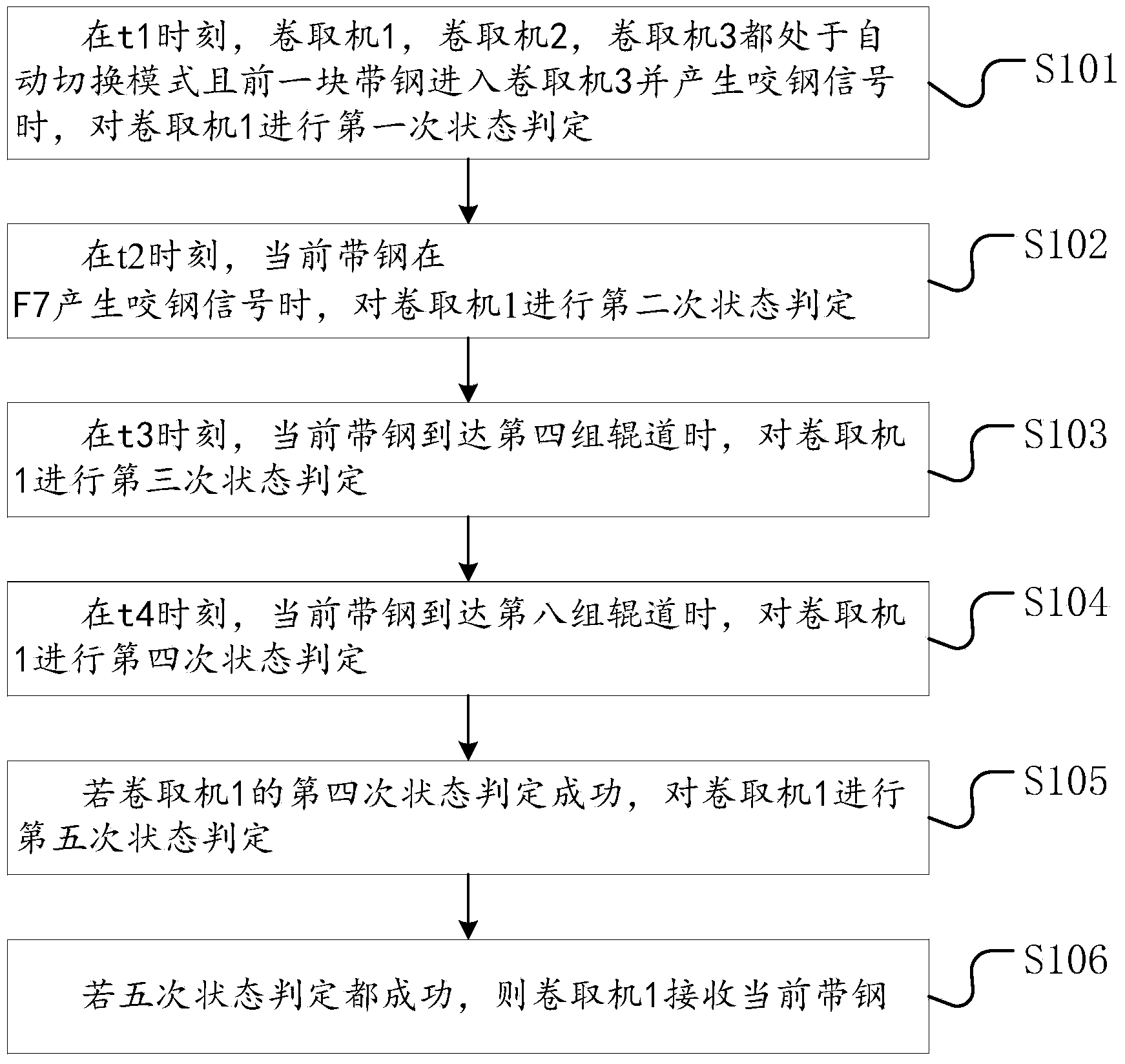

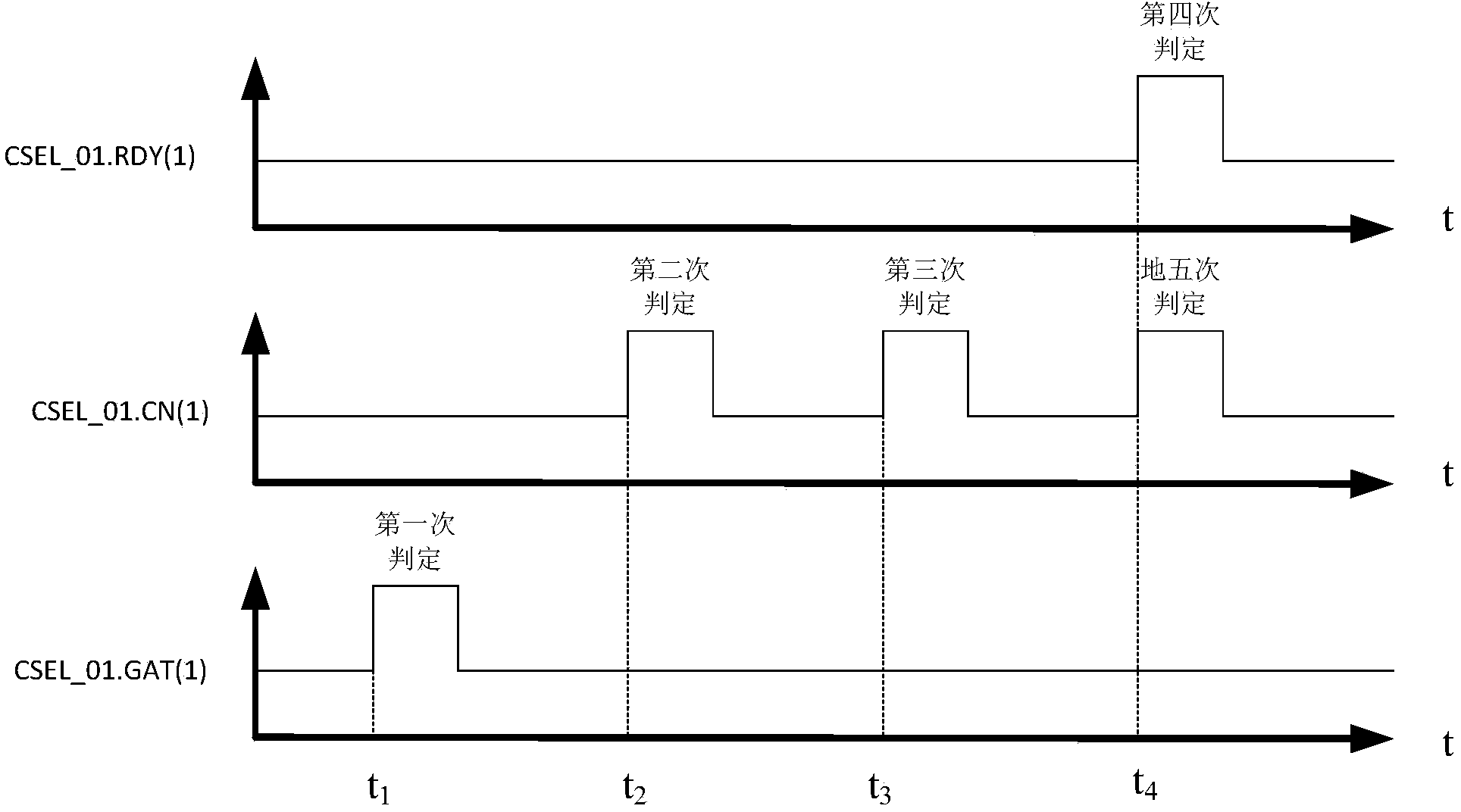

[0049] See below figure 1 , the specific implementation process of a hot rolling coiler switching method provided in the embodiment of the present invention is as follows:

[0050] S101, at time t1, coiler 1, coiler 2, and coiler 3 are all in the automatic switching mode, and when the previous piece of strip steel enters coiler 3 and generates a steel bite signal, the first coiler 1 is executed. A status determination. Wherein, the coiler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com