Dual-positioning floating turning clamp

A double-positioning, floating technology, applied in the direction of positioning devices, clamping devices, etc., can solve the problems of difficult clamping, low work efficiency, high tooling requirements, etc., to improve the pass rate and production efficiency, positioning operation Convenient and fast, high economic value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Aiming at the problem that it is difficult to clamp connecting rods with a single positioning fixture in the prior art, the present invention innovatively proposes a double-positioning floating turning fixture, which is convenient, quick and accurate in positioning the connecting rods.

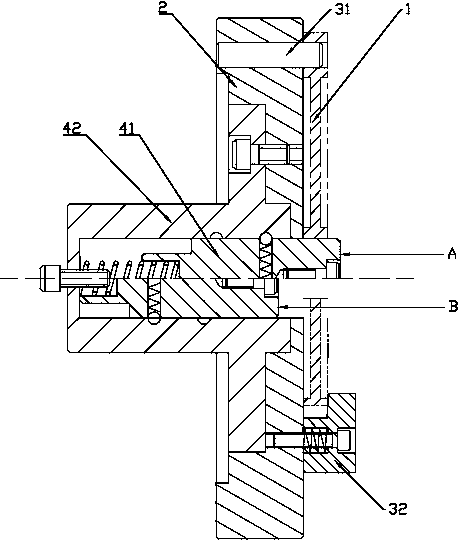

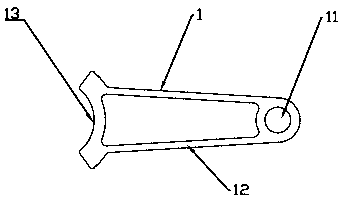

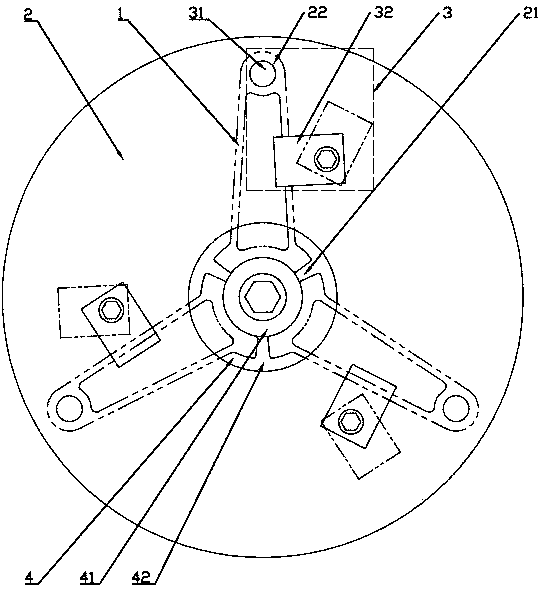

[0016] Such as Figure 1 to Figure 3 As shown, a double-positioning floating turning fixture is applied to the positioning and turning of the connecting rod 1. In particular, the connecting rod 1 has a positioning hole 11 , a connecting rod 12 and an arc groove 13 , and the double positioning floating turning fixture includes a clamp body 2 , a double positioning unit 3 and a telescopic sleeve mechanism 4 . Among them, the double positioning unit 3 is composed of a pin 31 and a wedge-shaped pressure plate 32, the clamp body 2 is provided with a central groove 21 and a pin hole 22, the telescopic sleeve mechanism 4 is installed in the central groove 21, and the wedge-shaped pressure plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com