A kind of LED guide light and its manufacturing method

A production method and technology of LED light source, applied in the directions of optics, light guide, light source, etc., can solve the problems of fragility and high cost of hollow glass bends, and achieve the effects of novel and elegant products, easy production, and expanded application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below in conjunction with accompanying drawing:

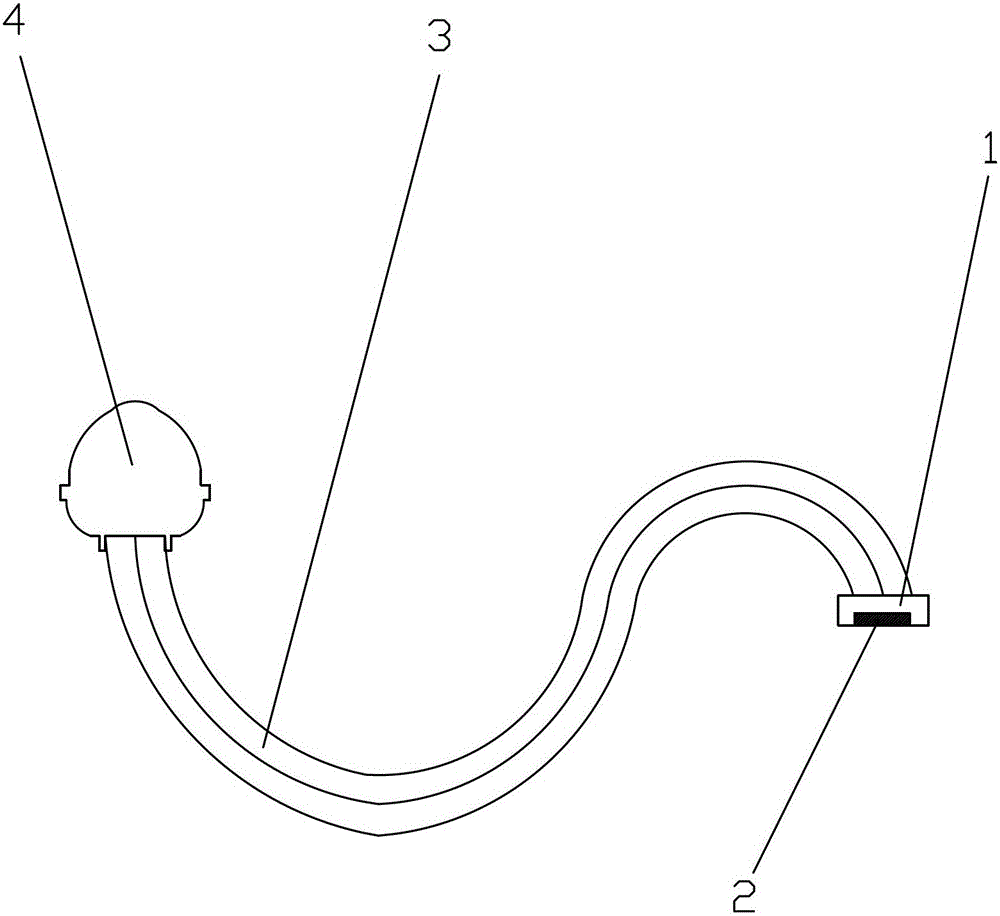

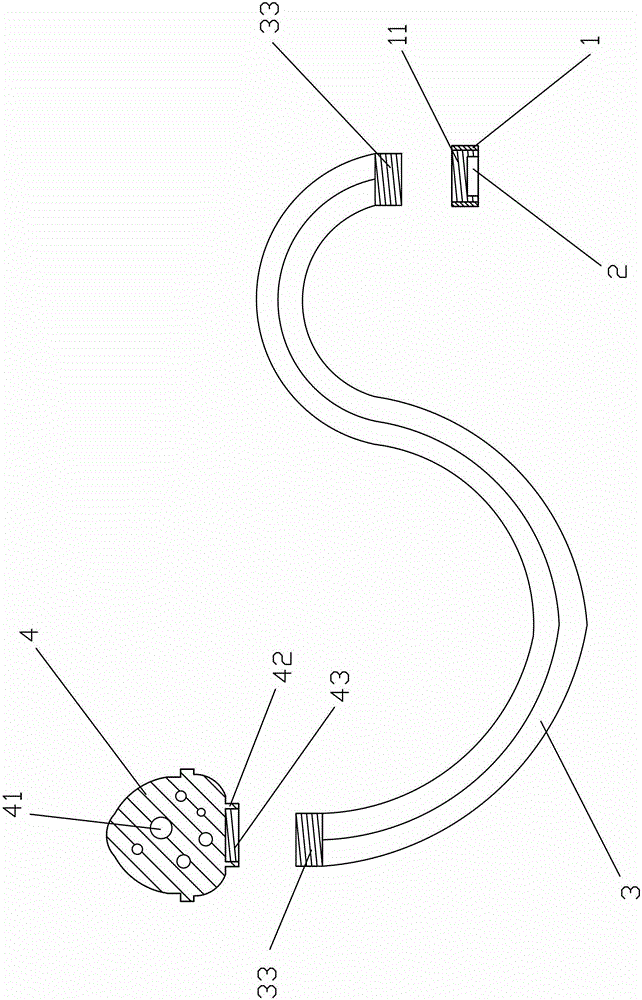

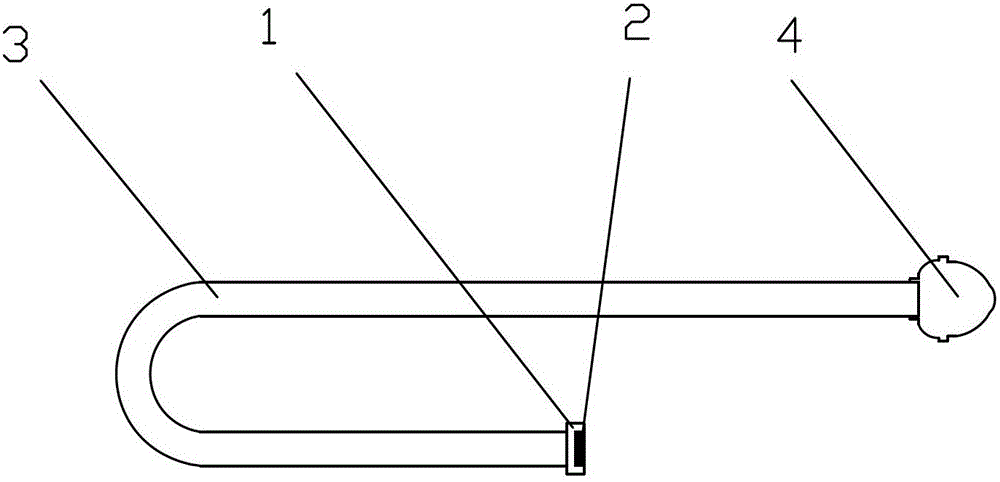

[0044] Such as Figure 1-12 As shown, an LED light guide lamp includes a lamp holder 1 and an LED light source 2 arranged in the lamp holder 1. A diffuser 4 is connected in front of the LED light source 2, and a cover is provided between the LED light source 2 and the diffuser 4. On the LED light source 2 , the light guide body 3 can transmit the light curve to the diffuser 4 .

[0045] The light guide body 3 is composed of a light guide tube 31 and a light guide core 32 filled in the light guide tube 31. The light guide tube 31 is integrally injection molded from polymethyl methacrylate, and the light guide core 32 is made of polymethyl methacrylate. The mixture of methyl methacrylate and nano-scale titanium oxide powder is integrally injection-molded in the light guide 31, wherein the weight ratio of polymethyl methacrylate and nano-scale titanium oxide powder is 99-99.5:1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com