Patents

Literature

81results about How to "Increase design space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

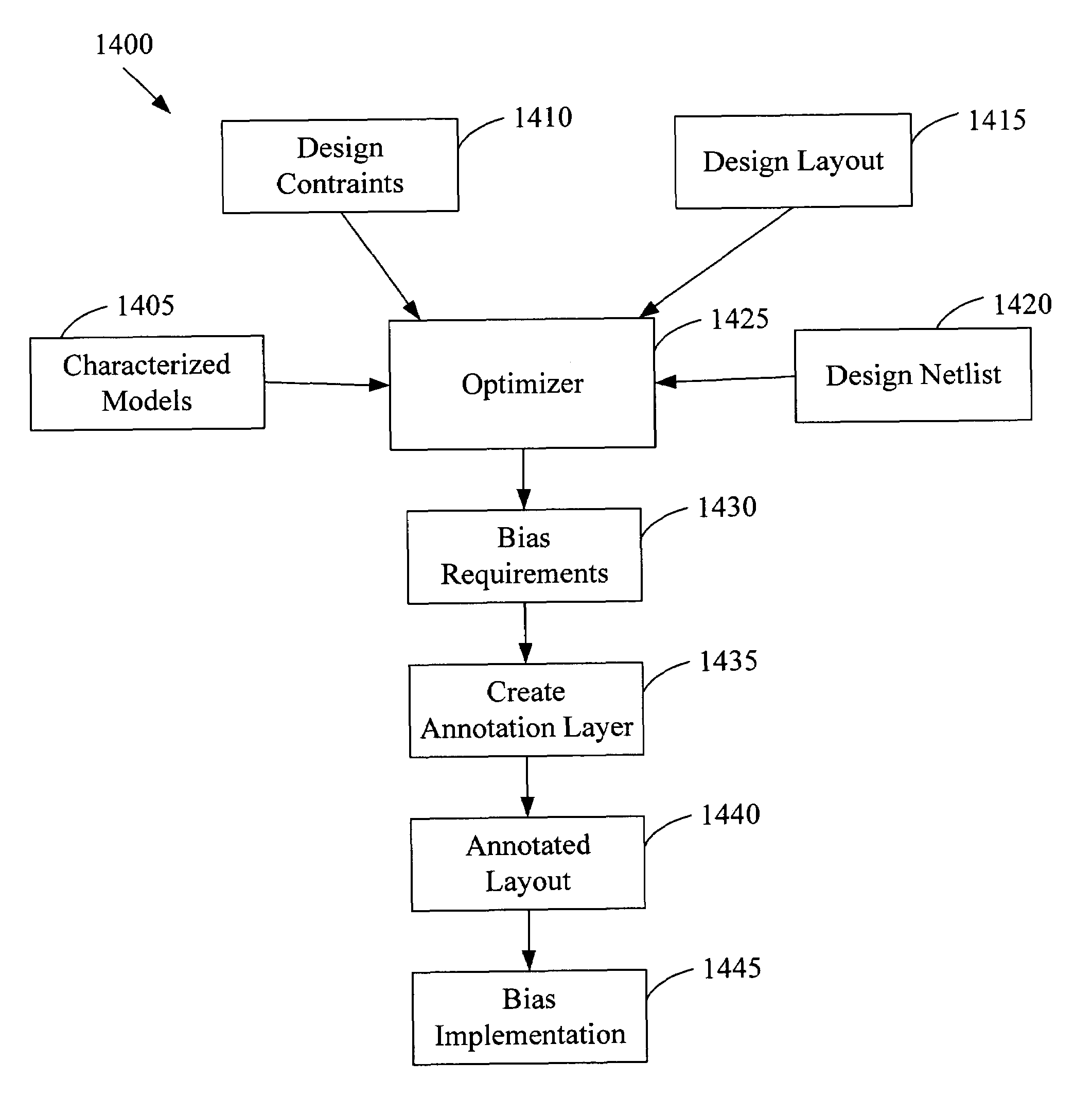

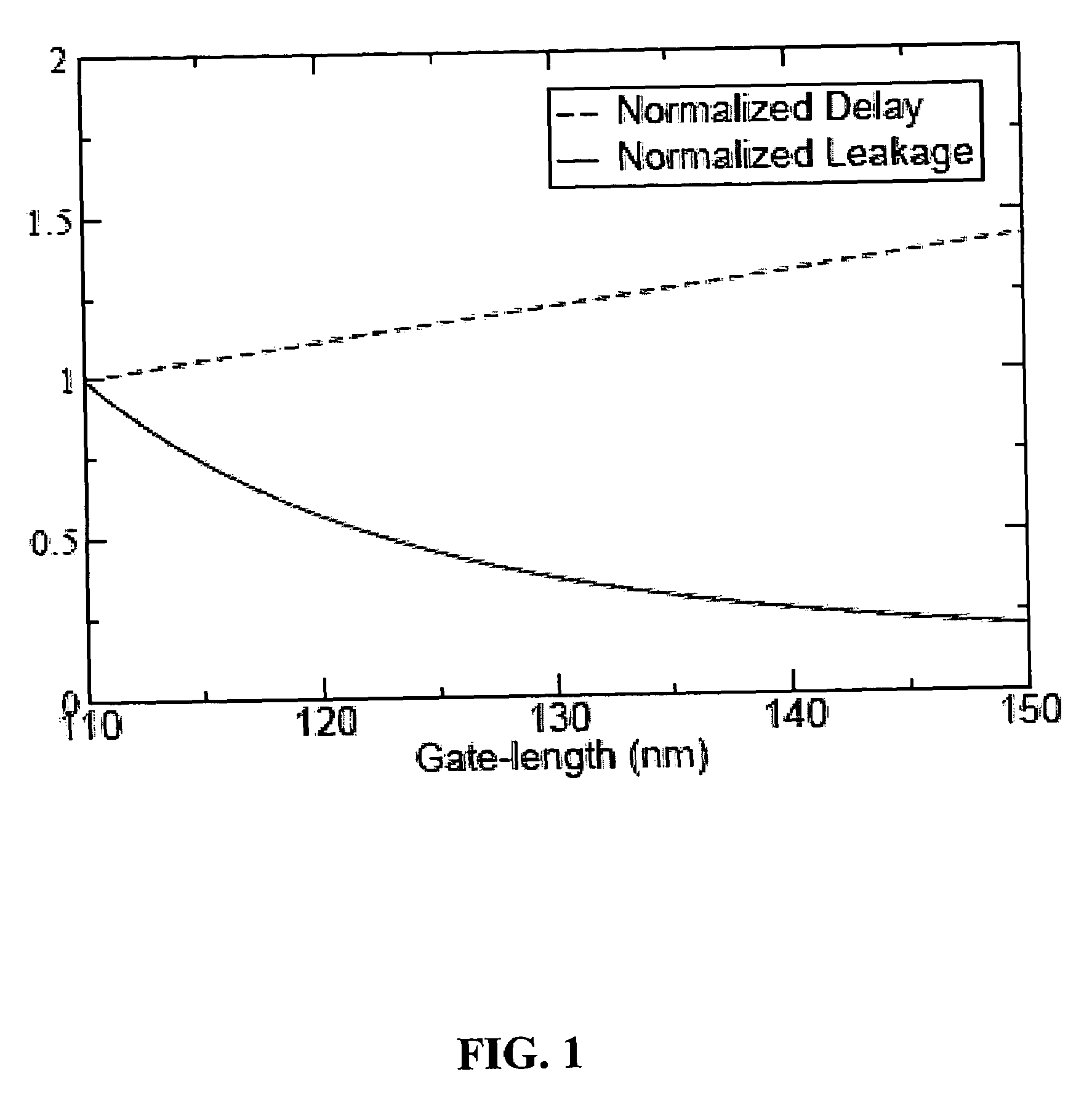

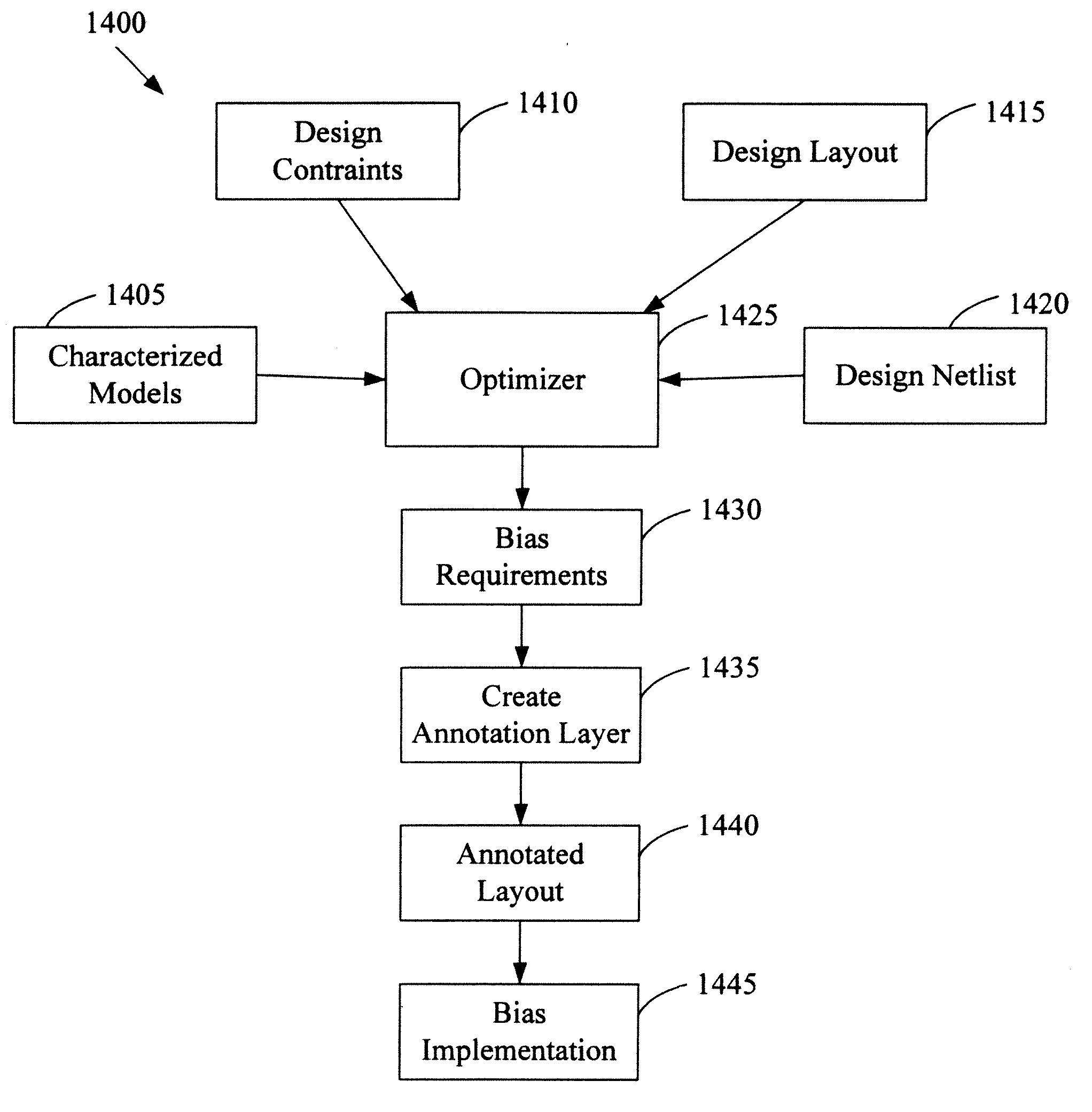

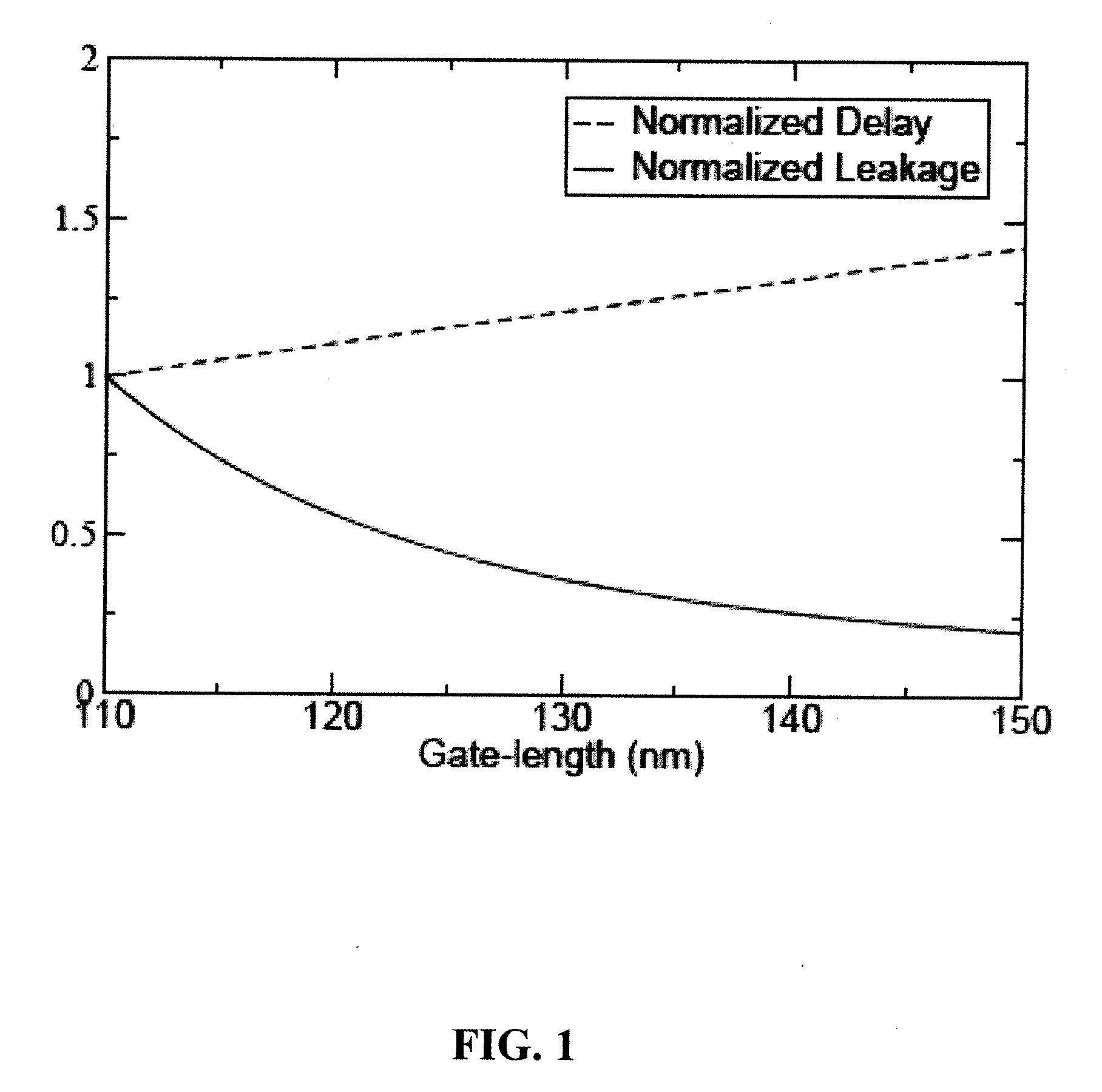

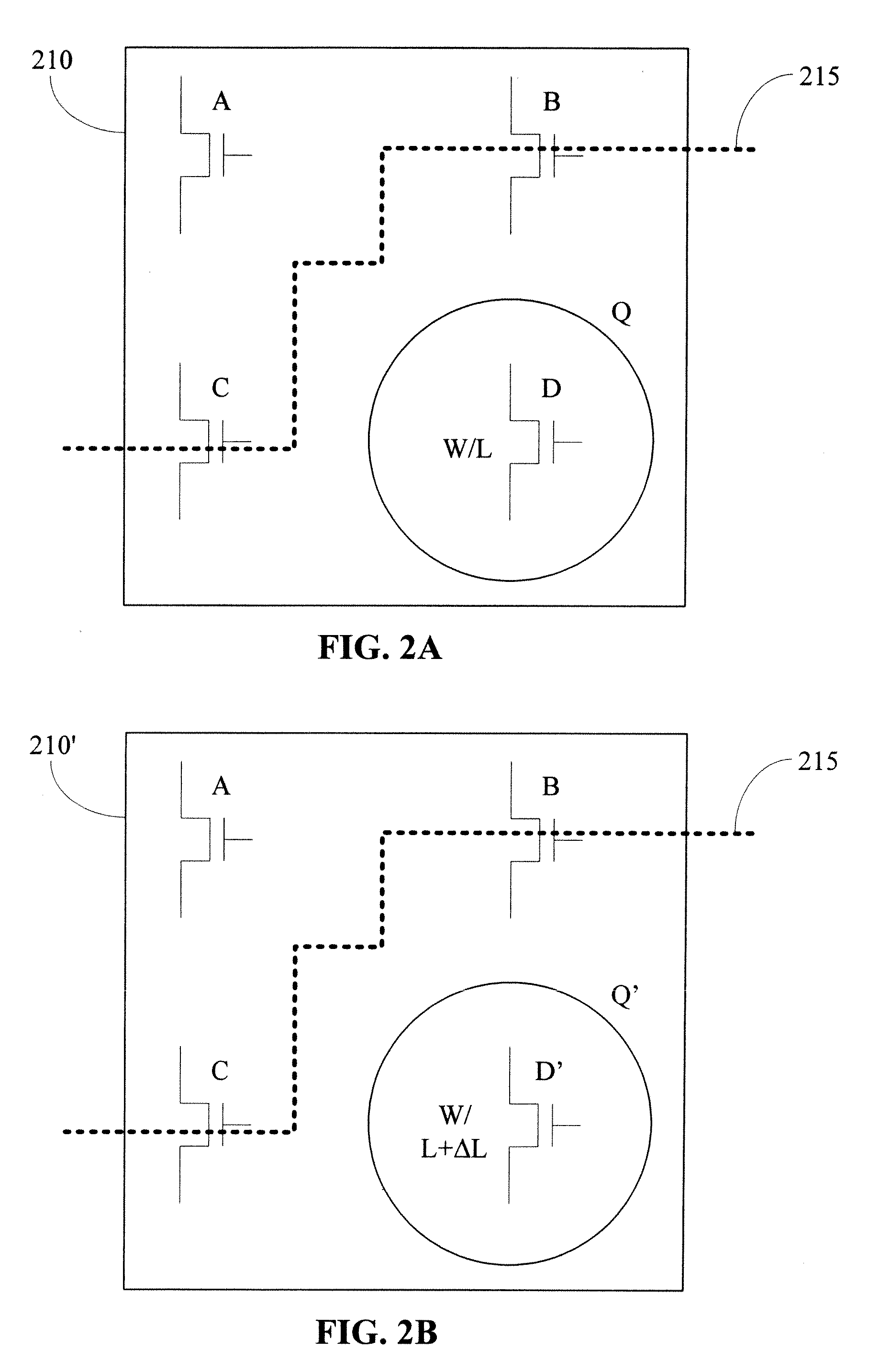

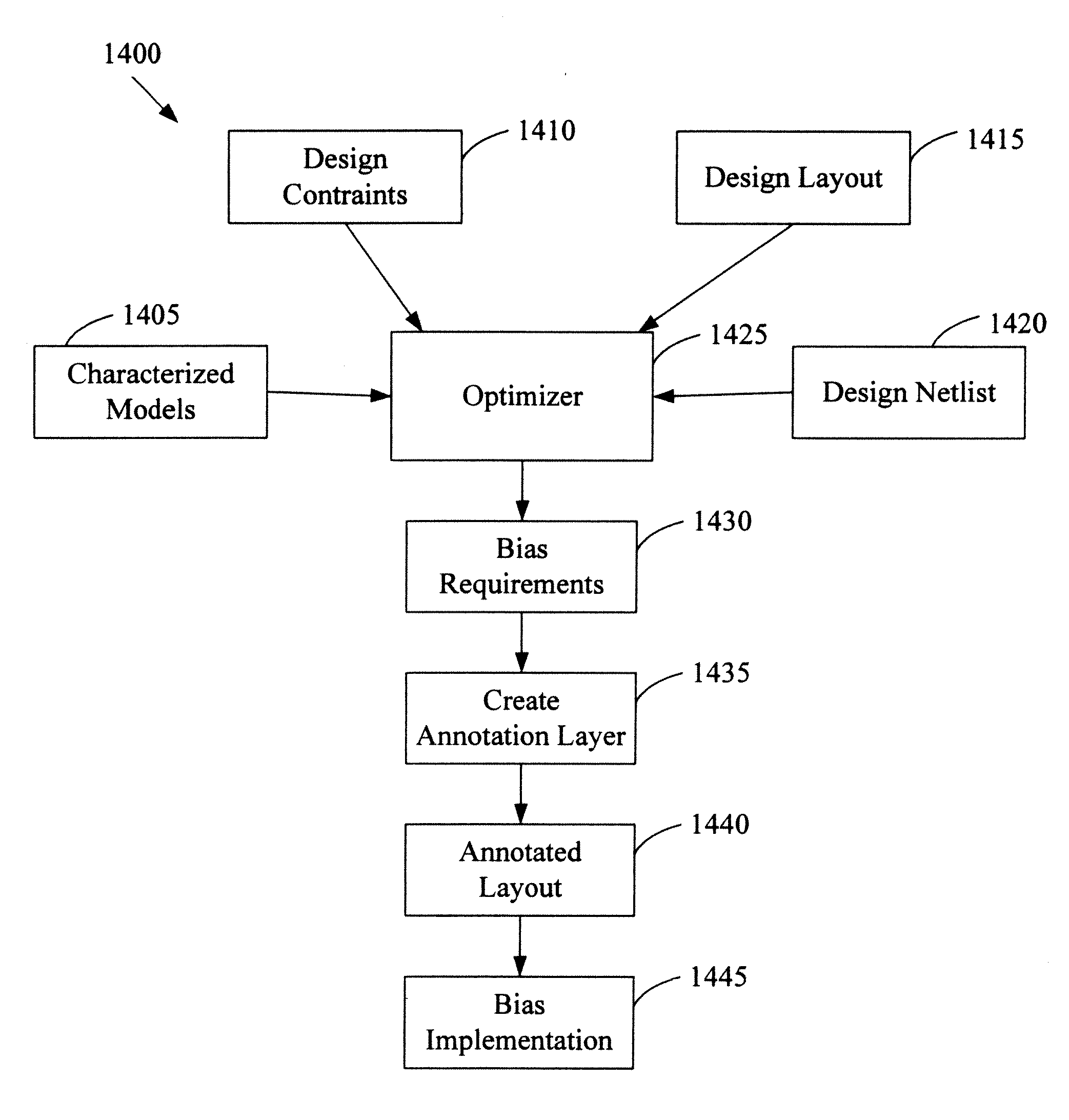

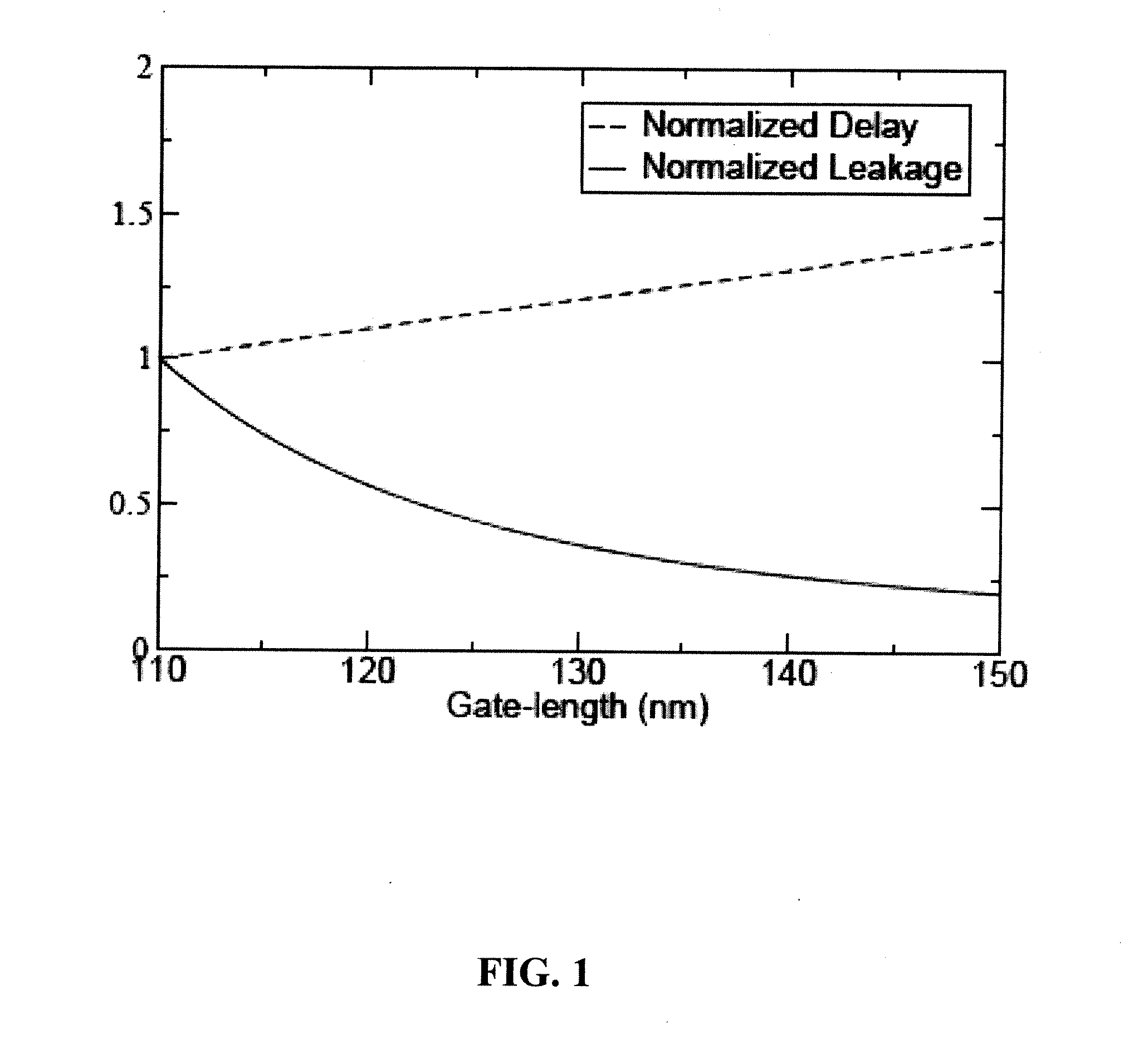

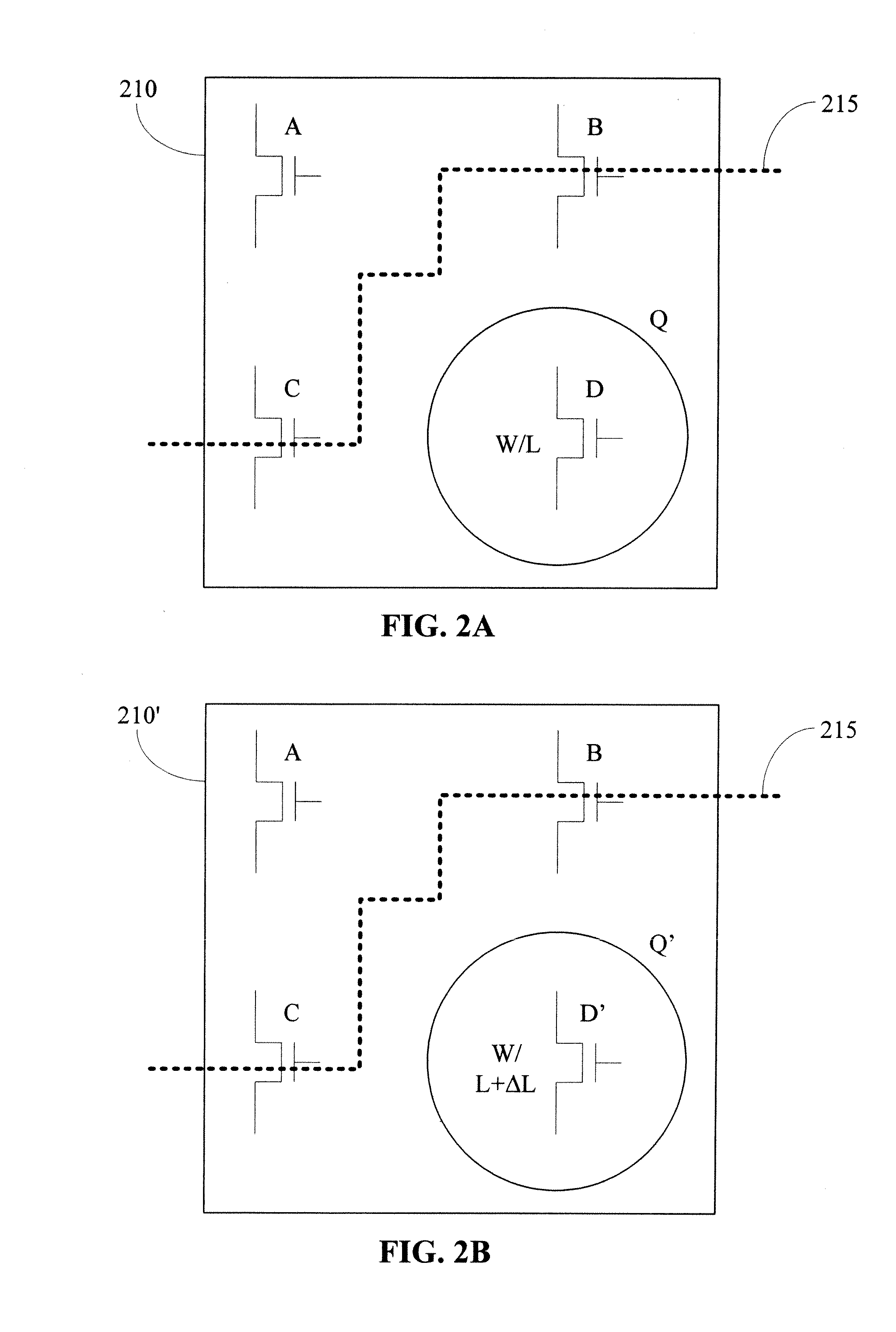

Gate-length biasing for digital circuit optimization

InactiveUS7441211B1Reduce impactImpairing time delay performance only linearlySolid-state devicesCAD circuit designEngineeringDigital electronics

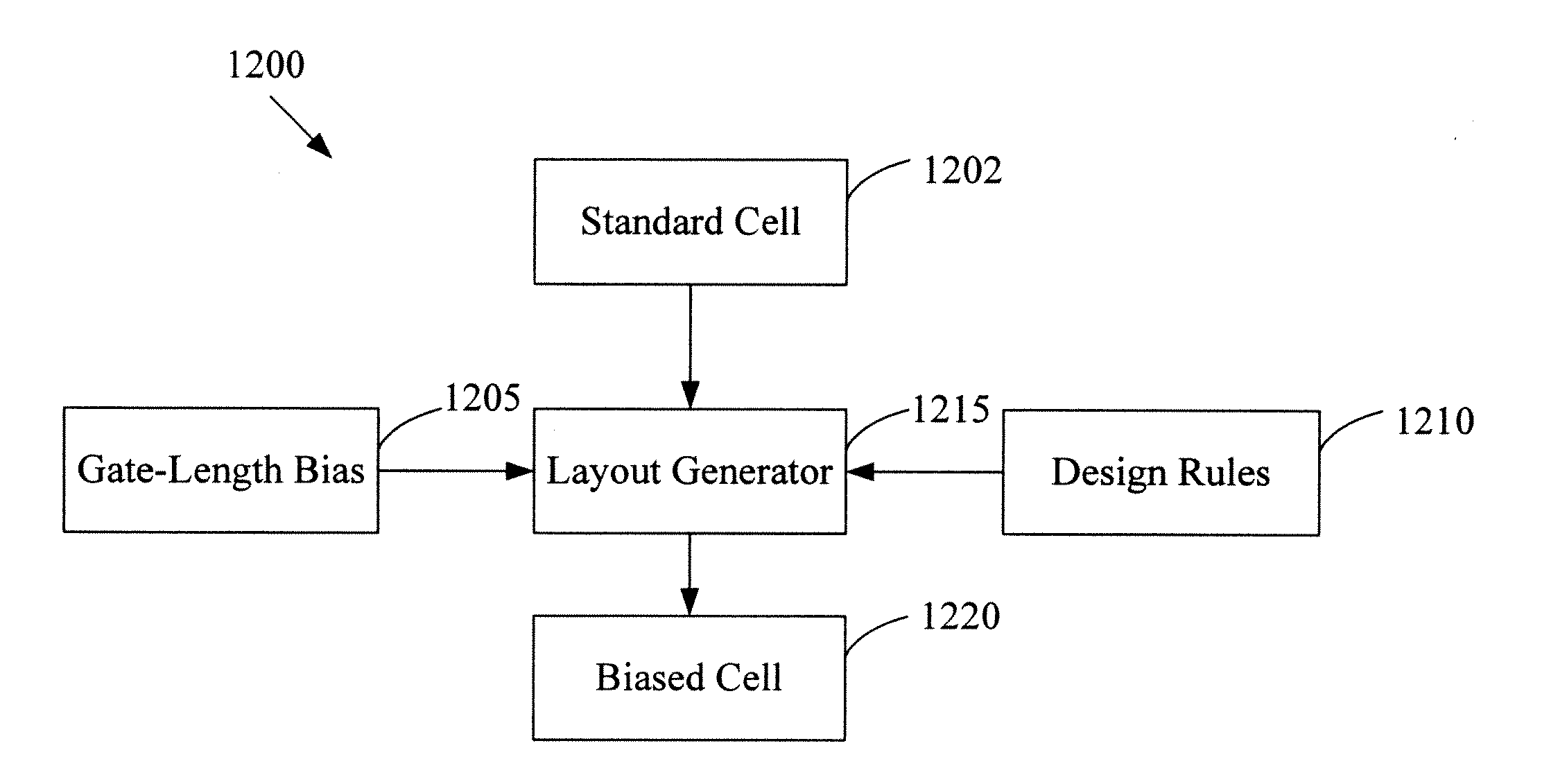

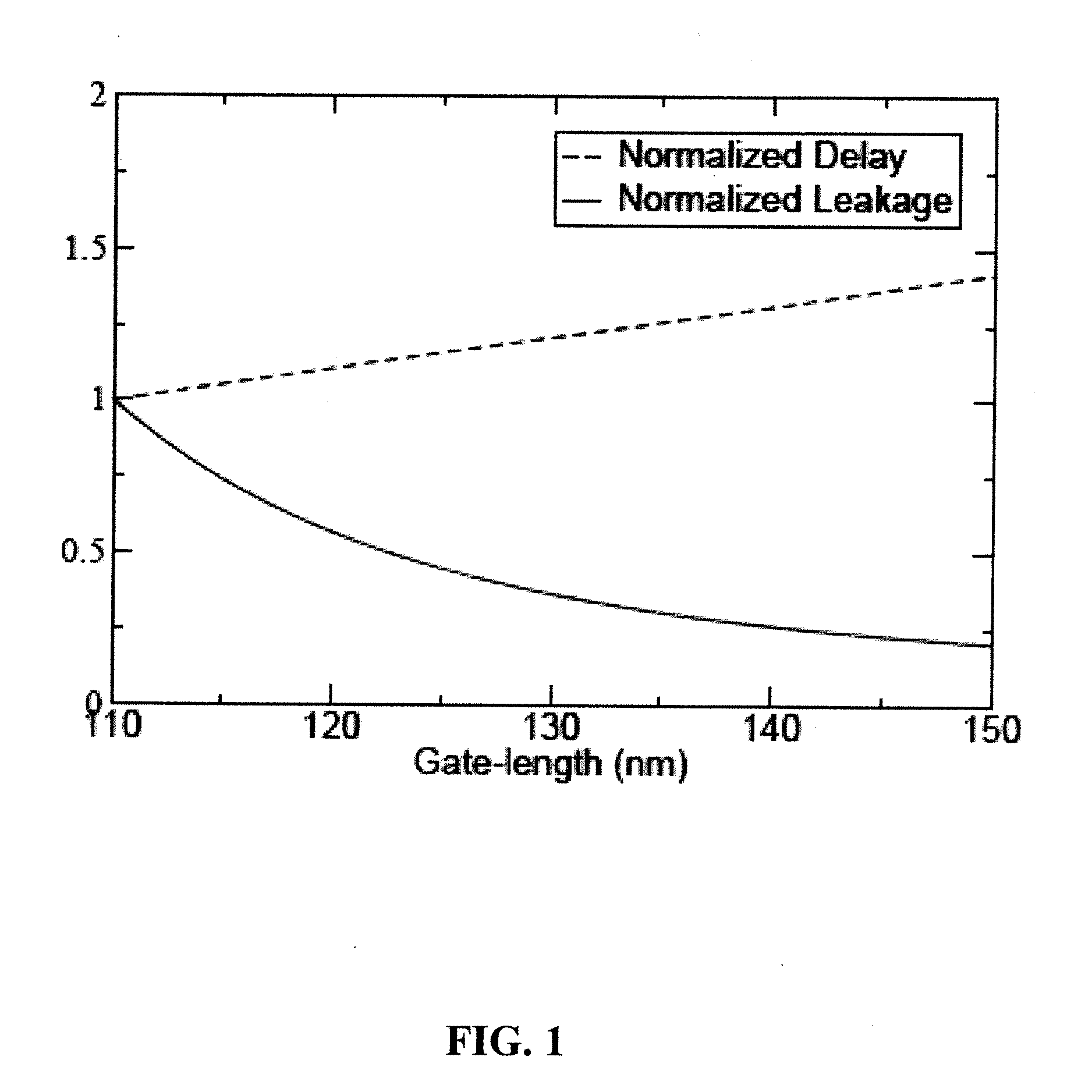

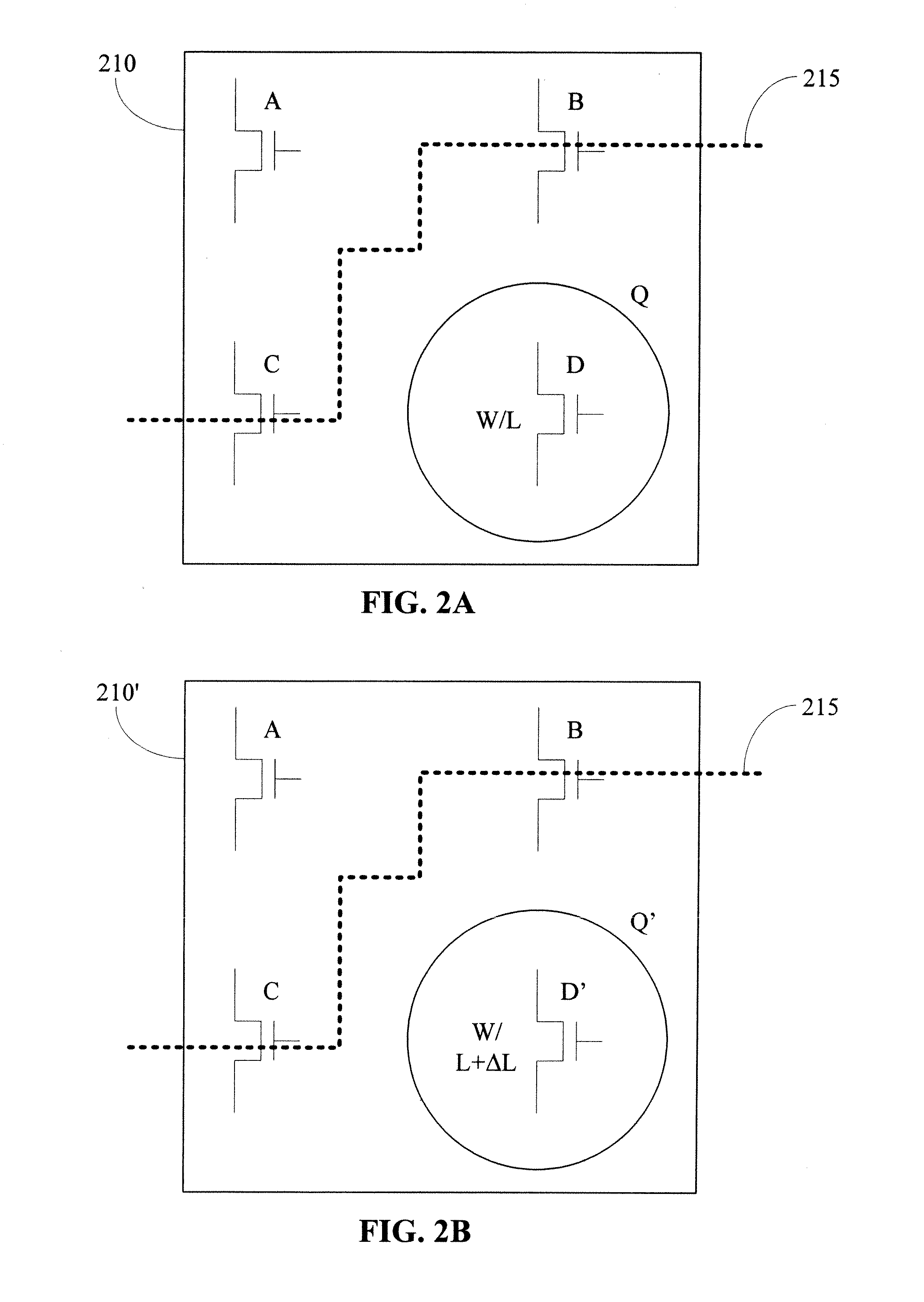

Methods and apparatus for a gate-length biasing methodology for optimizing integrated digital circuits are described. The gate-length biasing methodology replaces a nominal gate-length of a transistor with a biased gate-length, where the biased gate-length includes a bias length that is small compared to the nominal gate-length. In an exemplary embodiment, the bias length is less than 10% of the nominal gate-length.

Owner:RPX CORP

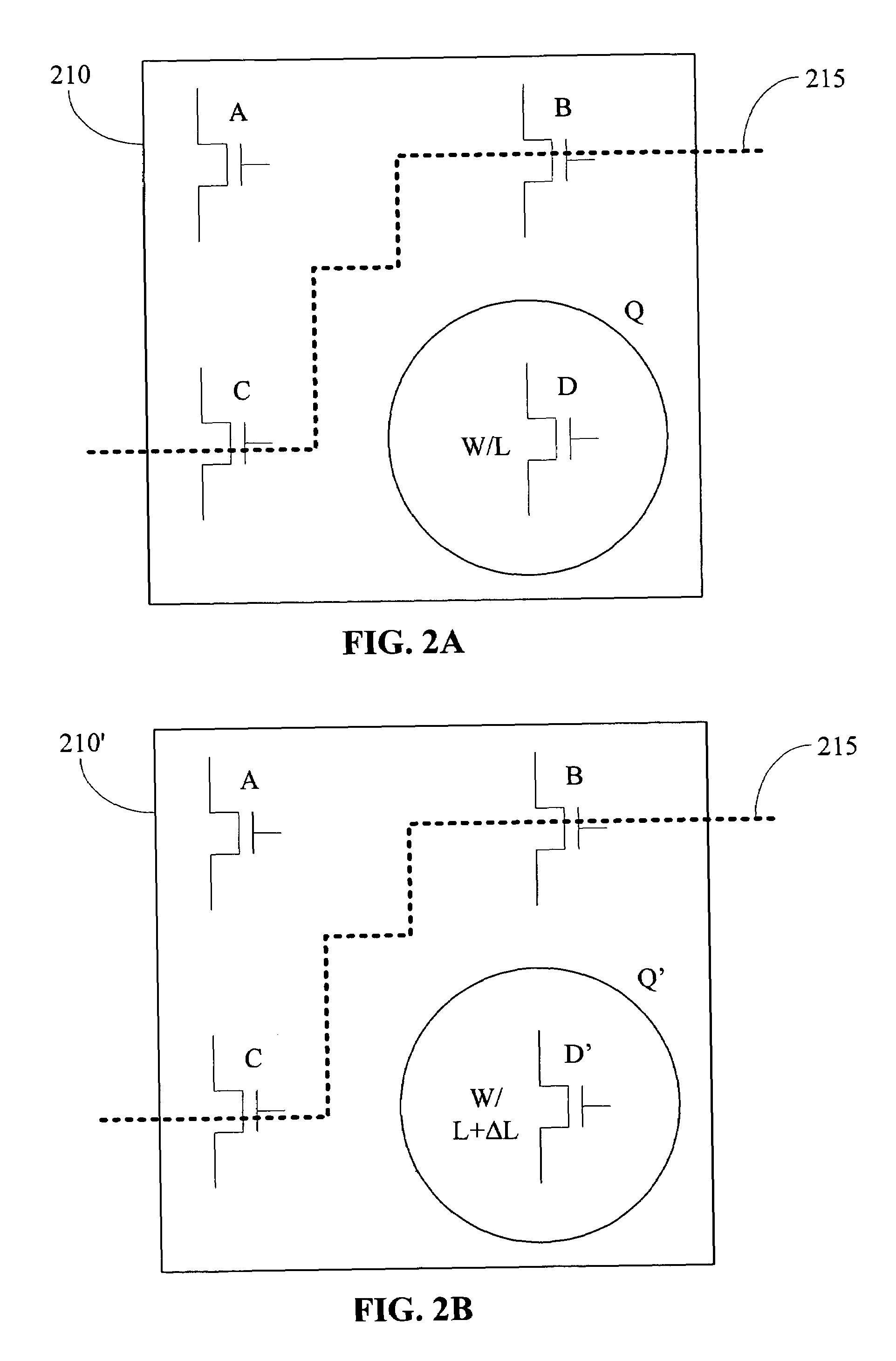

Standard cells having transistors annotated for gate-length biasing

InactiveUS20100169847A1Reduce impactImpairing time delay performance only linearlyCAD circuit designSpecial data processing applicationsSemiconductor chipAnnotation

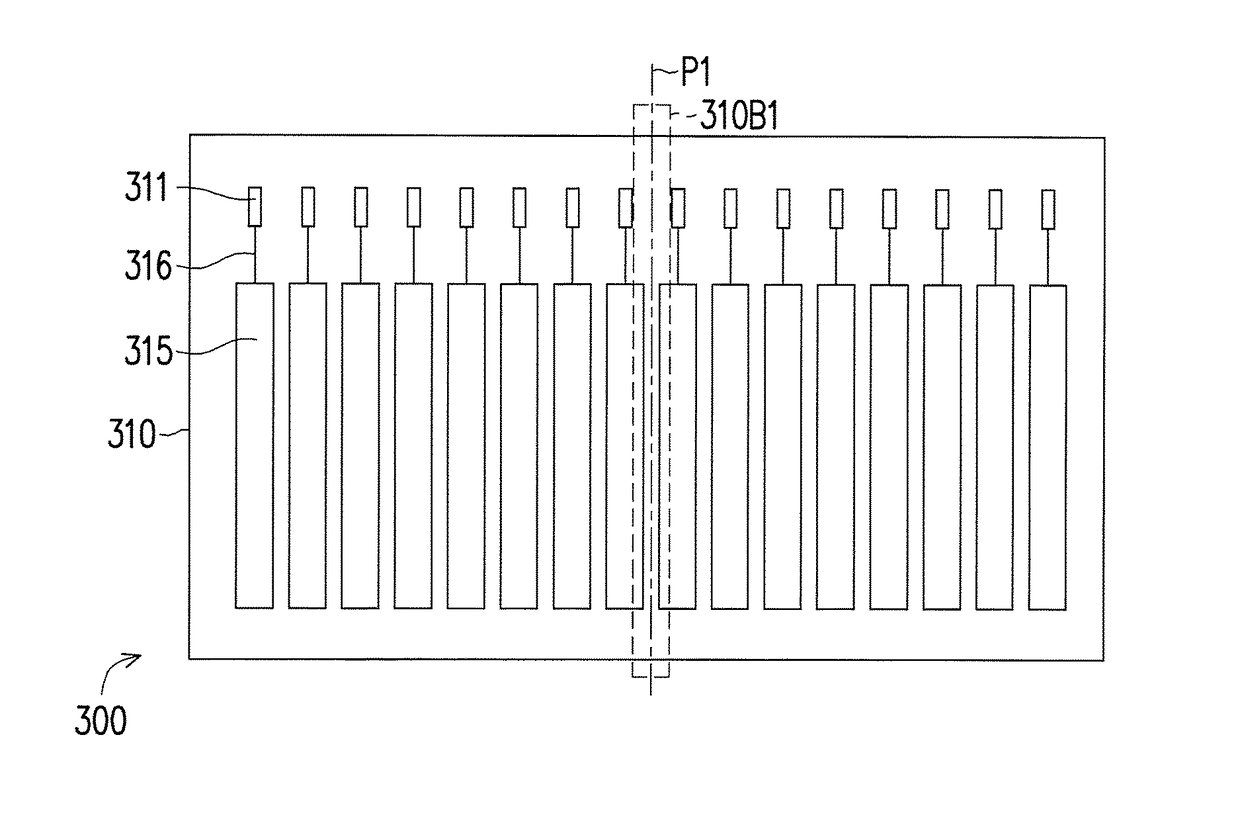

A standard cell library is disclosed. The standard cell library contains cells wherein at least one transistor in at least one cell is annotated for gate length biasing. Gate length biasing includes the modification of the gate length, so as to change the speed or power consumption of the modified gate length. The standard cell library is one used in the manufacturing of semiconductor devices (e.g., that result as semiconductor chips), by way of fabricating features defined on one or more layouts of geometric shapes. The annotations serve to identify which ones of the transistor gate features are to be modified before using the geometric shapes for manufacturing the semiconductor device.

Owner:RPX CORP

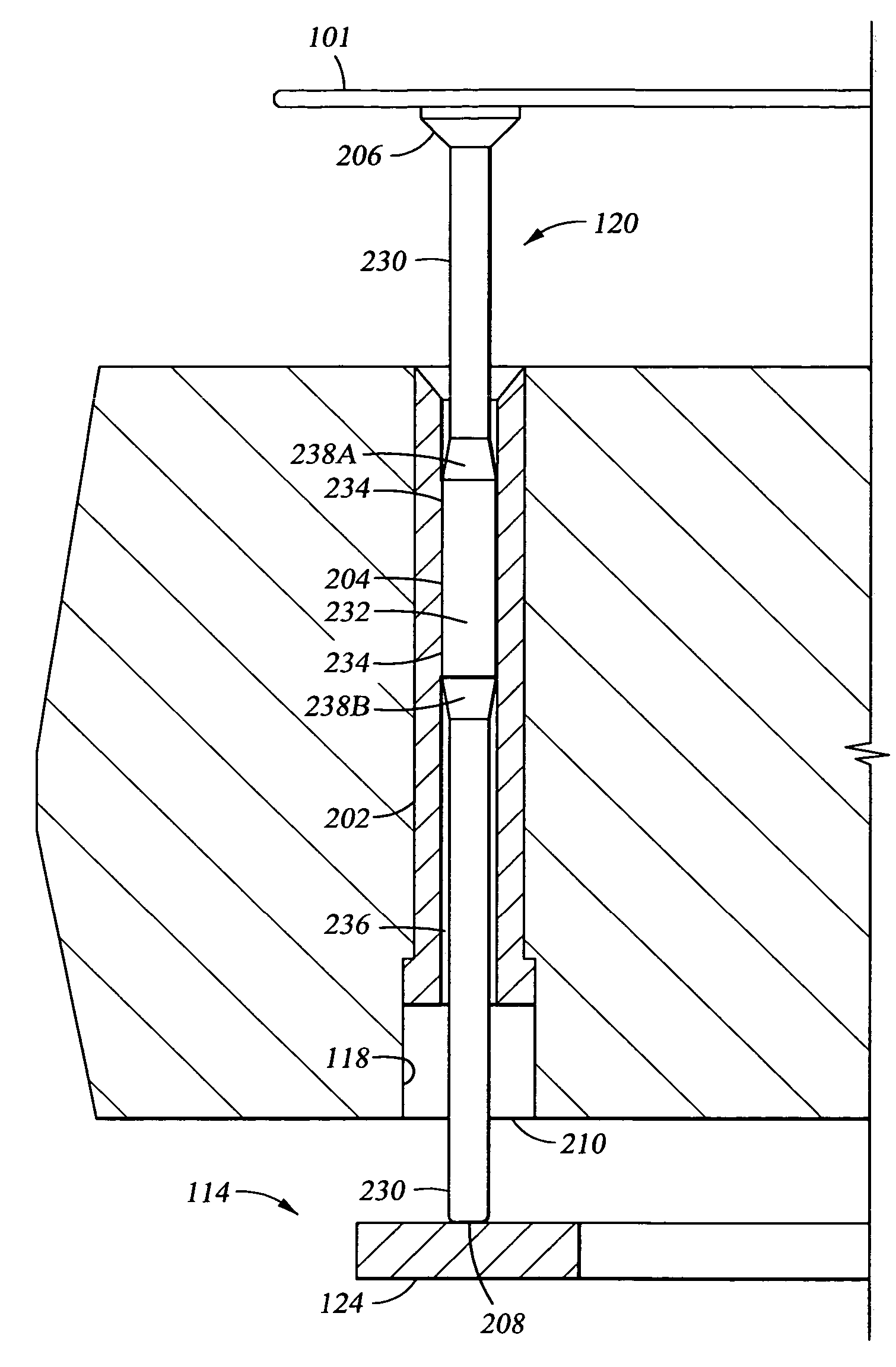

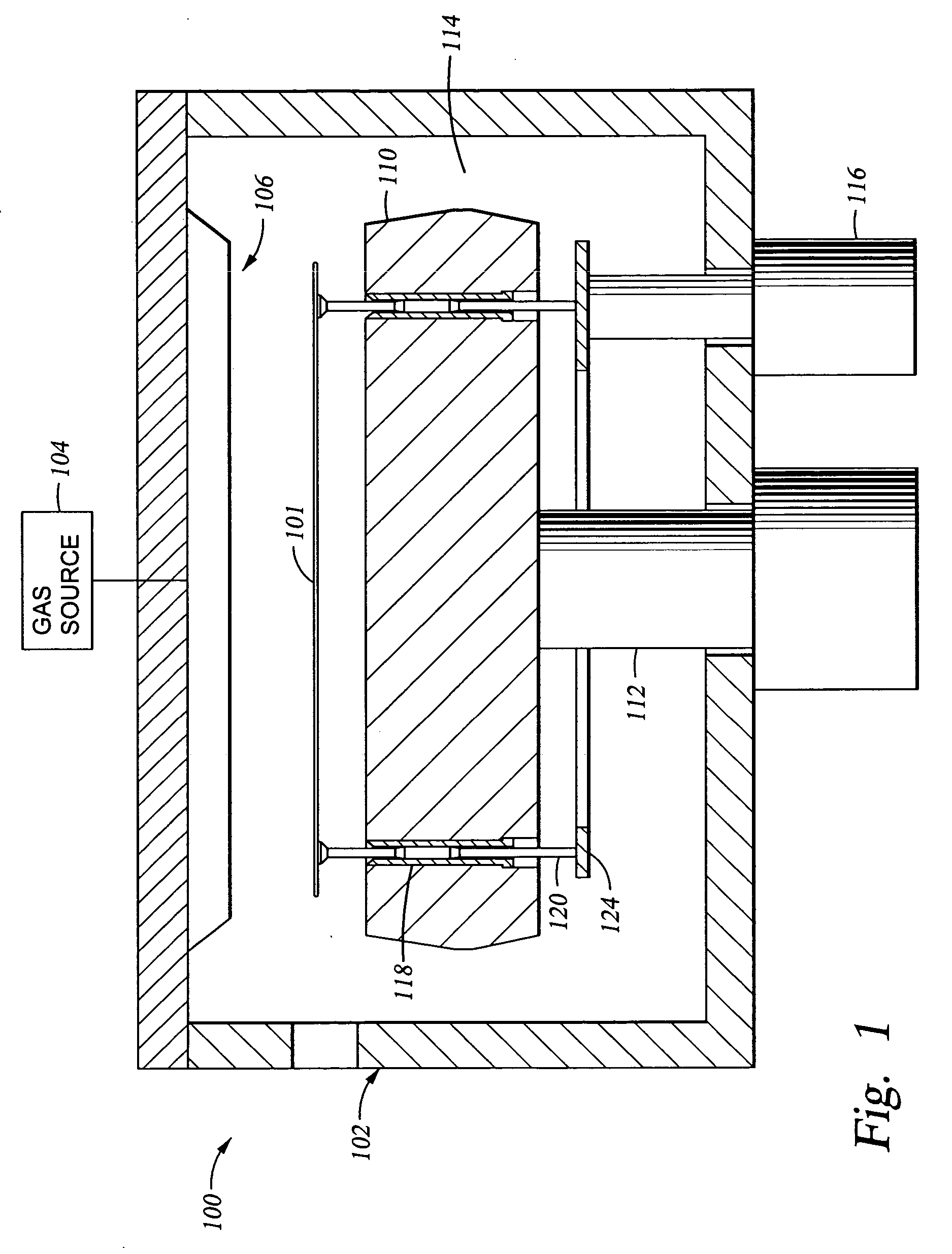

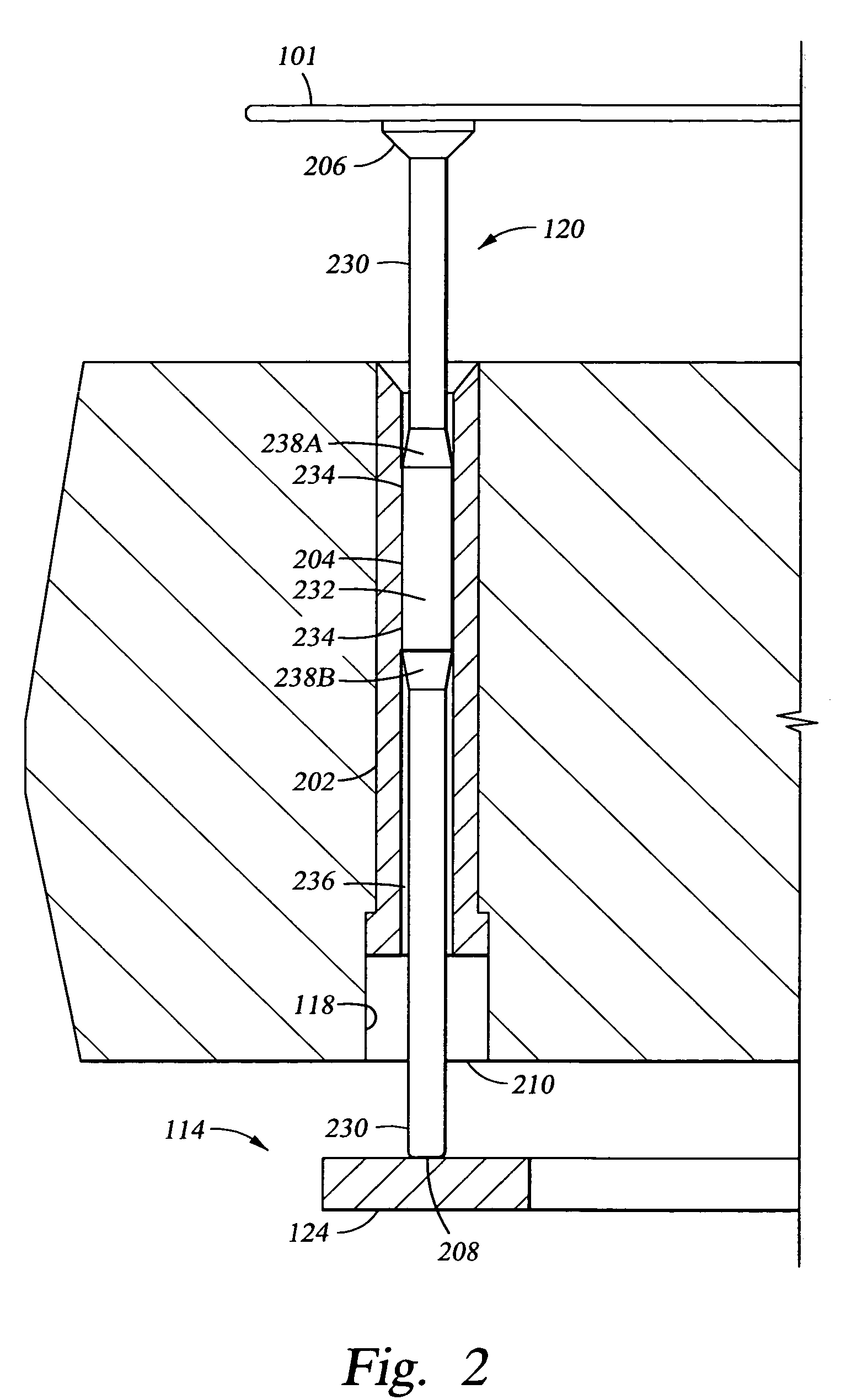

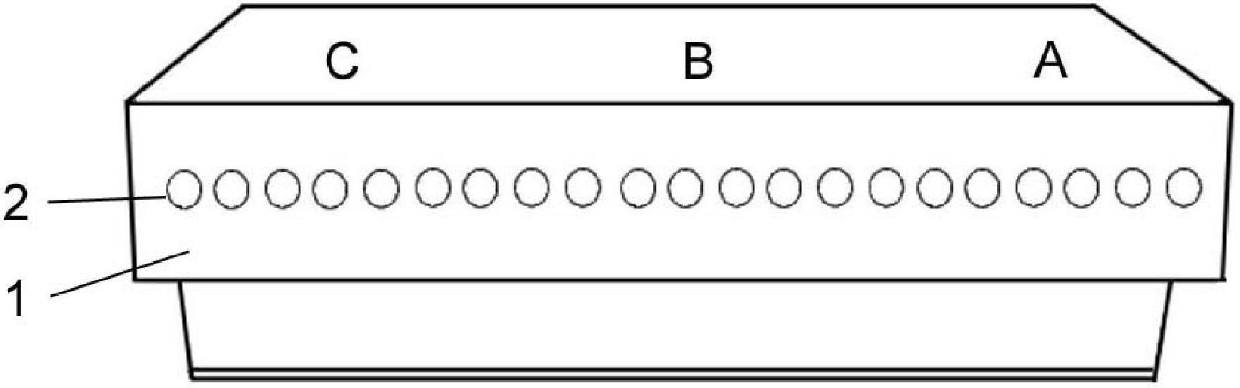

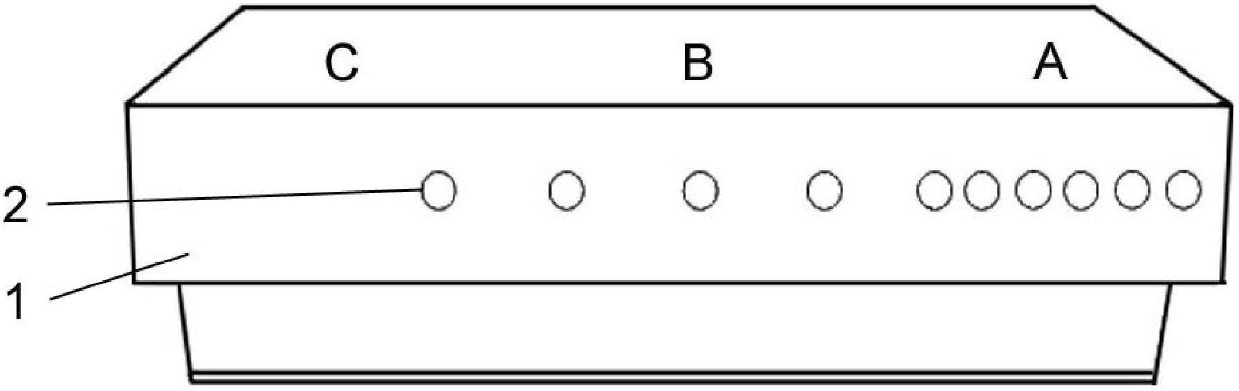

Reduced friction lift pin

InactiveUS20050194100A1Extended service lifePromote self-standingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingBiomedical engineeringScratching

A substrate support is provided that features a lift pin having at least one larger diameter shoulder section that forms a relief region between the lift pin and a guide hole disposed through a substrate support. The shoulder section minimizes contact between the substrate support and lift pin guide hole, thereby reducing pin scratching, particle generation, component wear, and increasing the useful life of the pin. In another embodiment, a flat-bottom tip is provided to promote self-standing of the lift pin, reducing pin tilting or leaning of the lift pin within the guide hole.

Owner:APPLIED MATERIALS INC

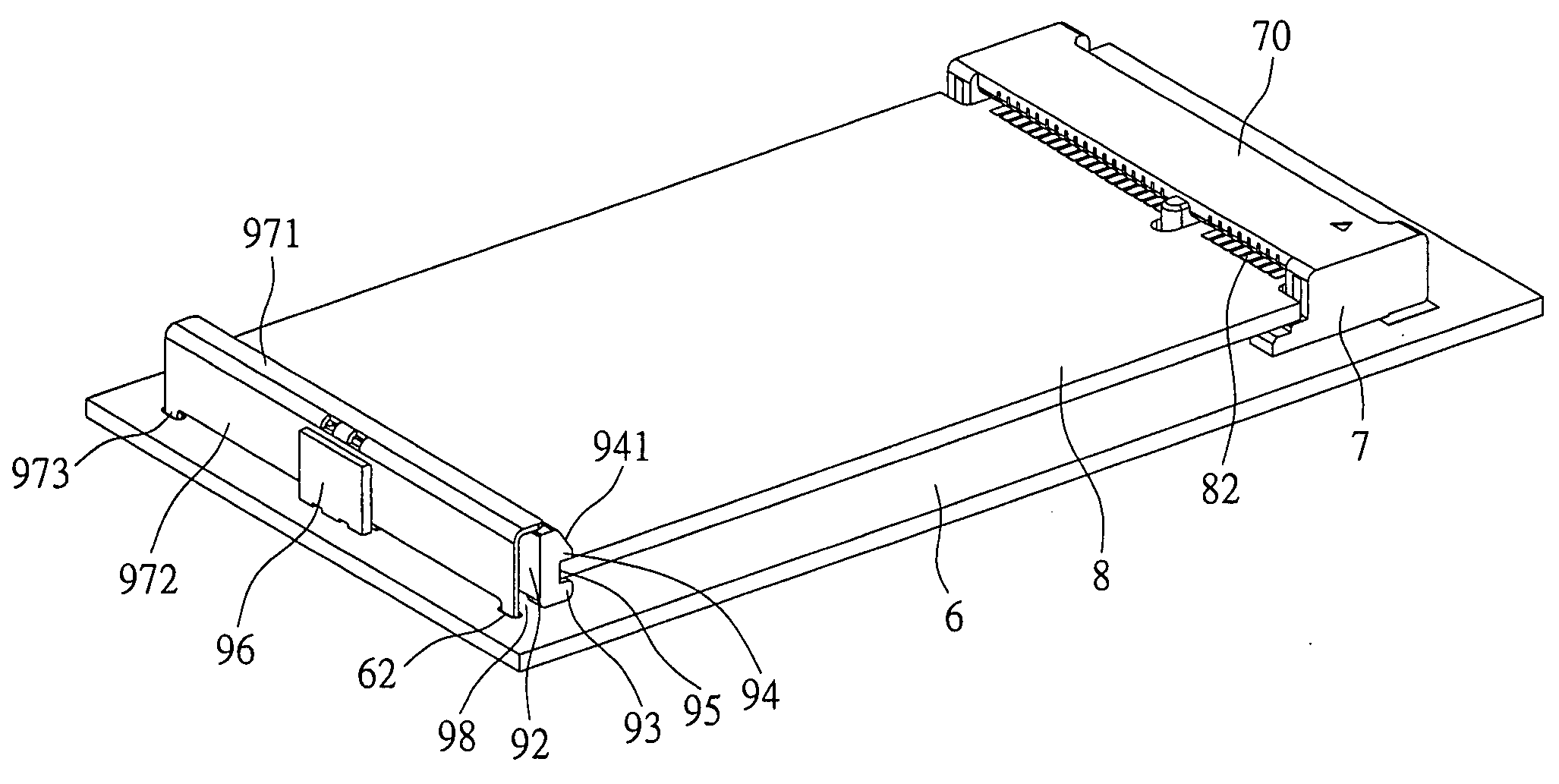

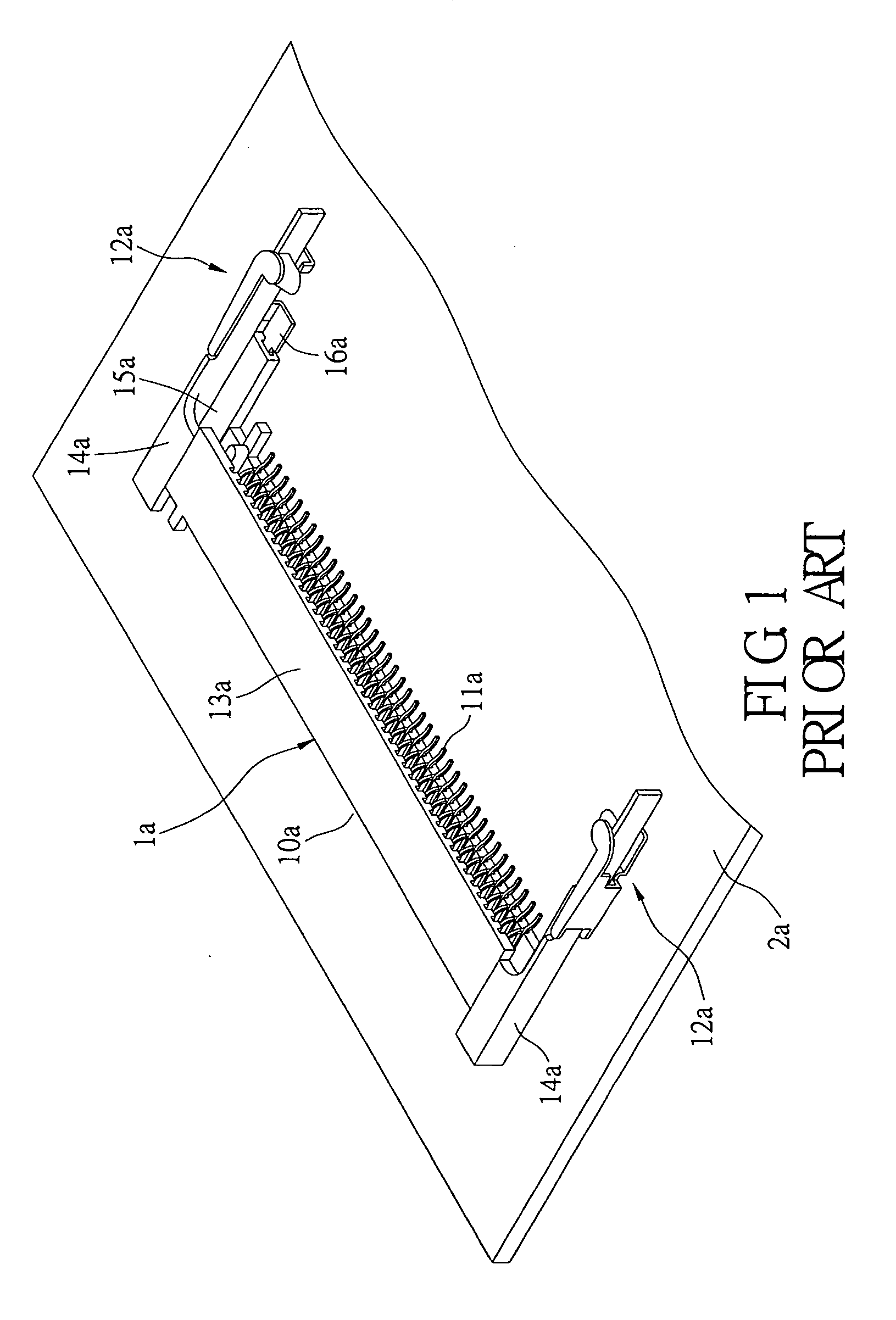

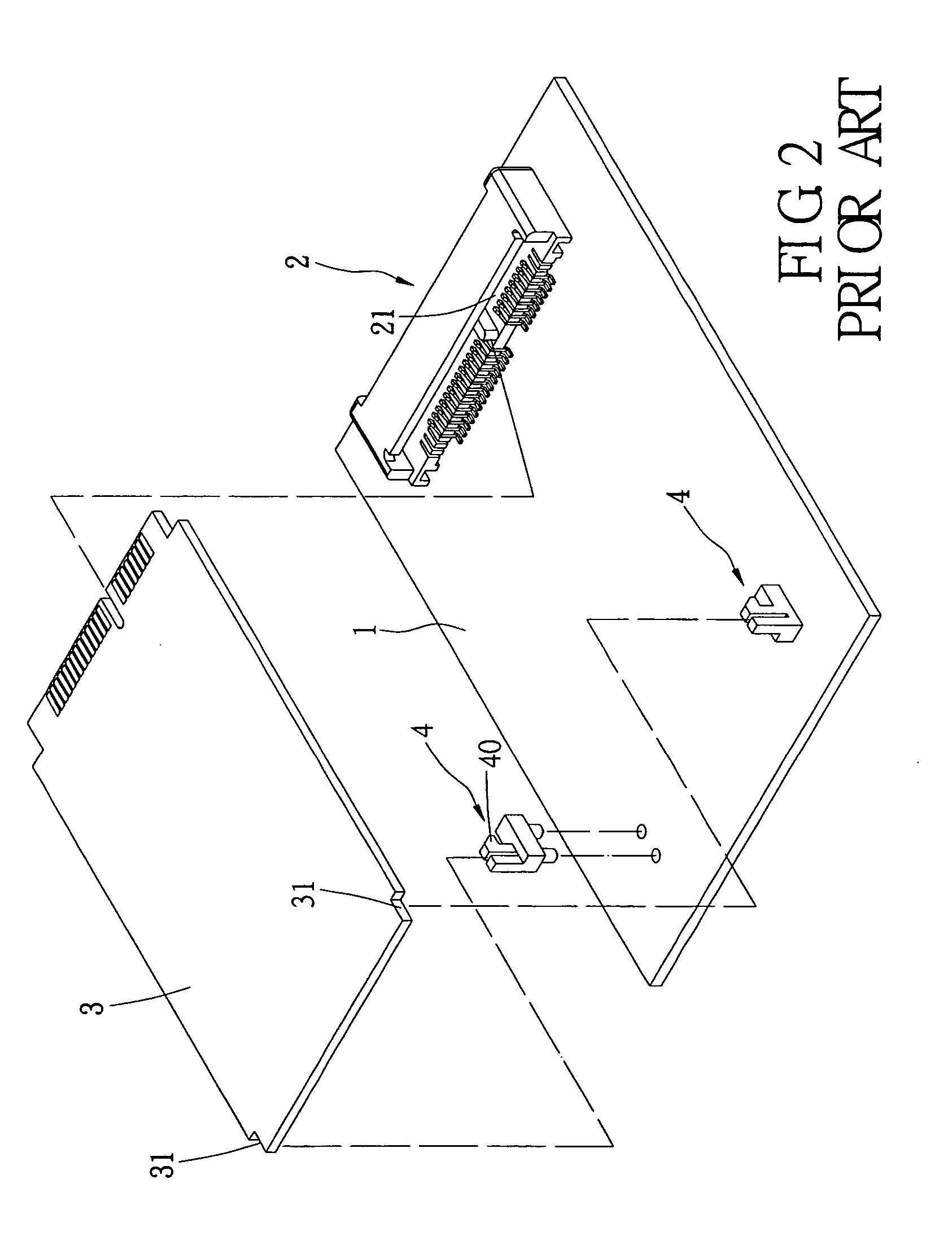

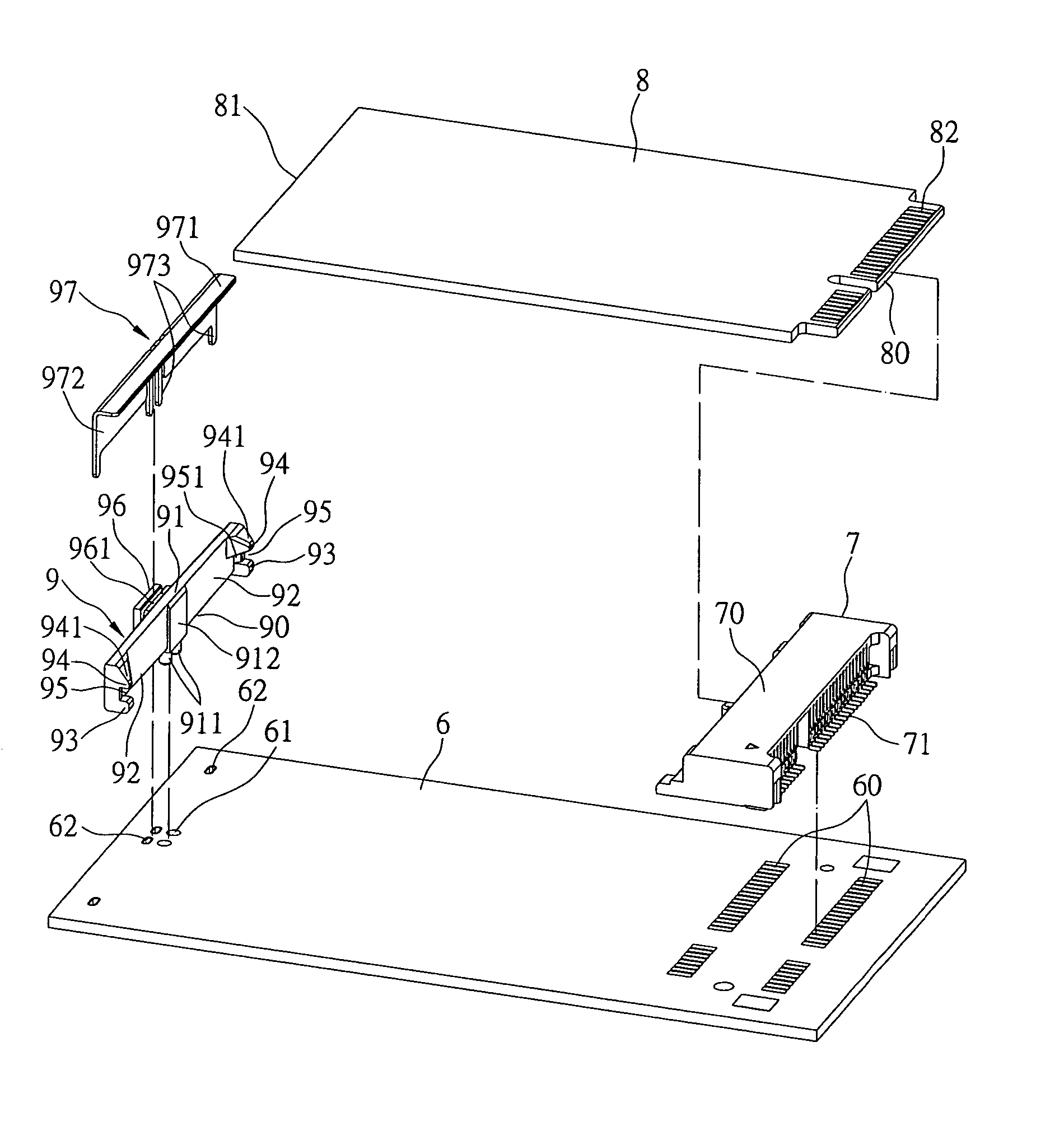

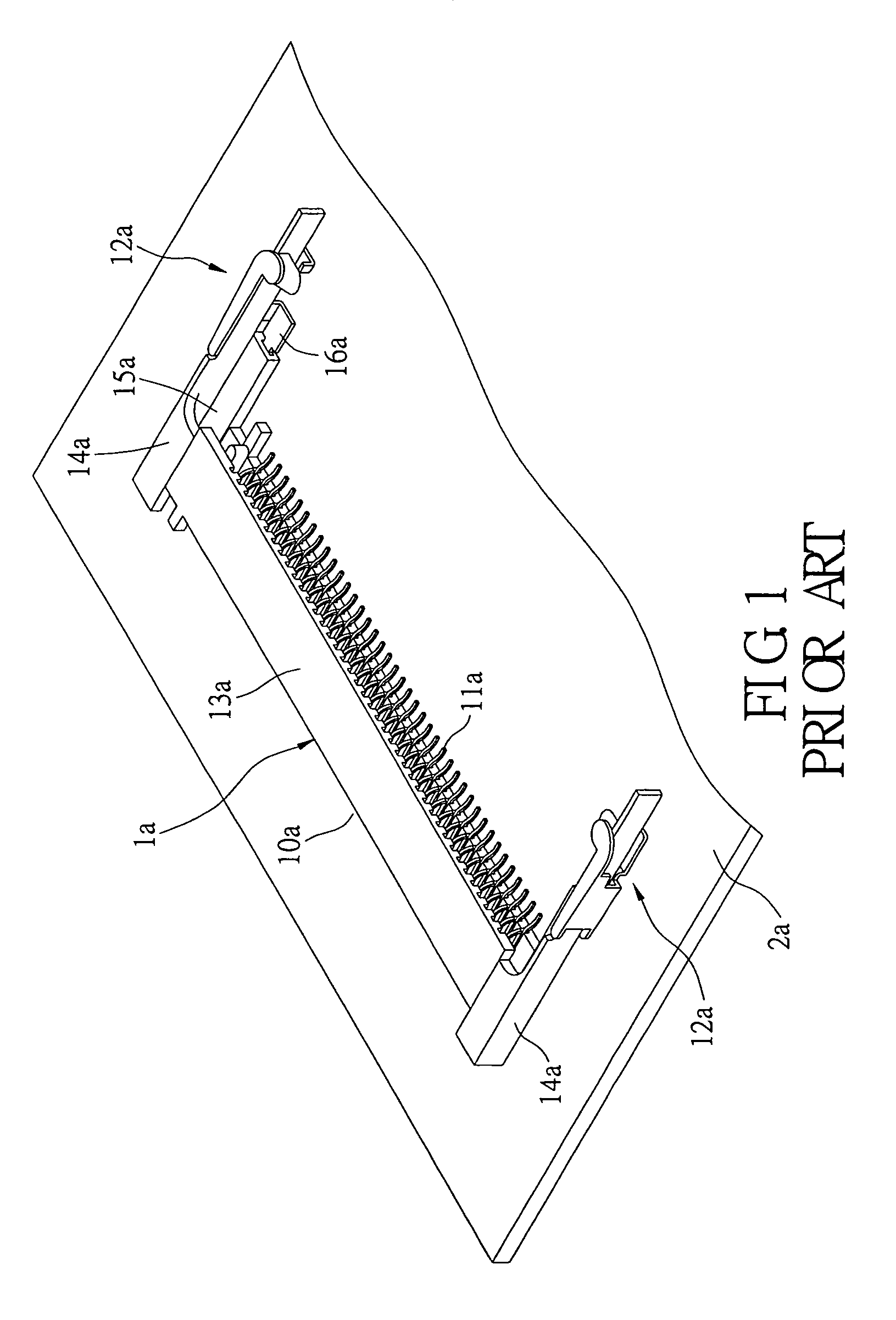

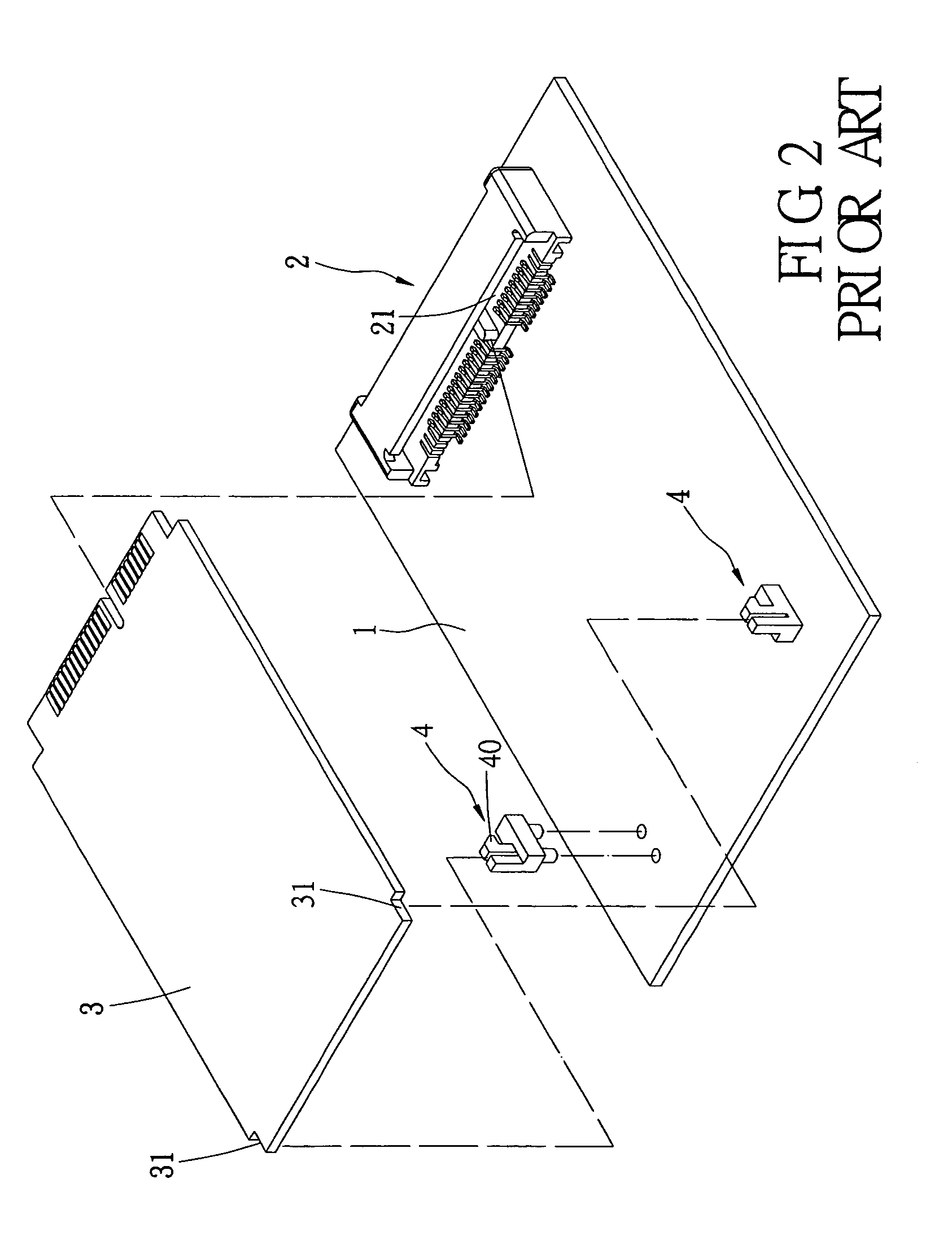

Card edge connector assembly

ActiveUS20050048828A1Avoid abrasionsAvoid breakingEngagement/disengagement of coupling partsTwo-part coupling devicesShock resistanceEngineering

A card edge connector assembly includes a circuit board, a connector, an electrical card and a fixing structure. The connector is formed on the circuit board, the front rim of the electrical card is inserted into the insertion slot of the connector. The fixing structure has an elastic element having a fixing portion positioned on the circuit board. Two relating opposing sides of the fixing portion extends two elastic arms whose free ends form a beveled edge and a clasp portion, and define positioning slots on the rear rim of the electrical card. The length of the elastic arm increases in such a way that the elasticity of the elastic arm becomes greater so as to prevent the elastic arm abrading and breaking to ensure the positioning function and enhance the shock-resistance.

Owner:MOLEX INC

Methods for gate-length biasing using annotation data

InactiveUS20100169846A1Reduce impactImpairing time delay performance only linearlySolid-state devicesCAD circuit designEngineeringIntegrated circuit

Methods for generating a biased layout for making an integrated circuit are disclosed. One such method includes obtaining a nominal layout defined by one or more cells, where each cell has one or more transistor gate features with a nominal gate length. Then, obtaining an annotated layout. The annotated layout contains information describing gate-length biasing of one or more of the transistor gate features in one or more cells of the nominal layout. A biased layout is produced by modifying the nominal layout using the information from the annotated layout. The biasing modifies a gate length of those transistor gate features identified by the information of the annotated layout.

Owner:RPX CORP

Touch display device and manufacturing method thereof

InactiveUS20170131809A1Avoid damageEfficient signal transmissionDigital data processing detailsInput/output processes for data processingDisplay deviceElectrode

A touch display device and a manufacturing method thereof are provided. The touch display device includes a flexible touch display panel, a plurality of first pads, a plurality of touch electrodes and a plurality of conducting wires. The flexible touch display panel includes a first bending area bending along a first bending axis. The first pads are disposed on the flexible touch display. The touch electrodes are disposed on the flexible touch display. The conducting wires are disposed on the flexible touch display. A plurality of first terminals of the conducting wires is electrically coupled to the touch electrodes respectively, and a plurality of second terminals of the conducting wires is electrically coupled to the first pads respectively. Conducting wires having a direction different from the axial direction of the first bending axis are not disposed in the first bending area of the flexible touch display panel.

Owner:ACER INC

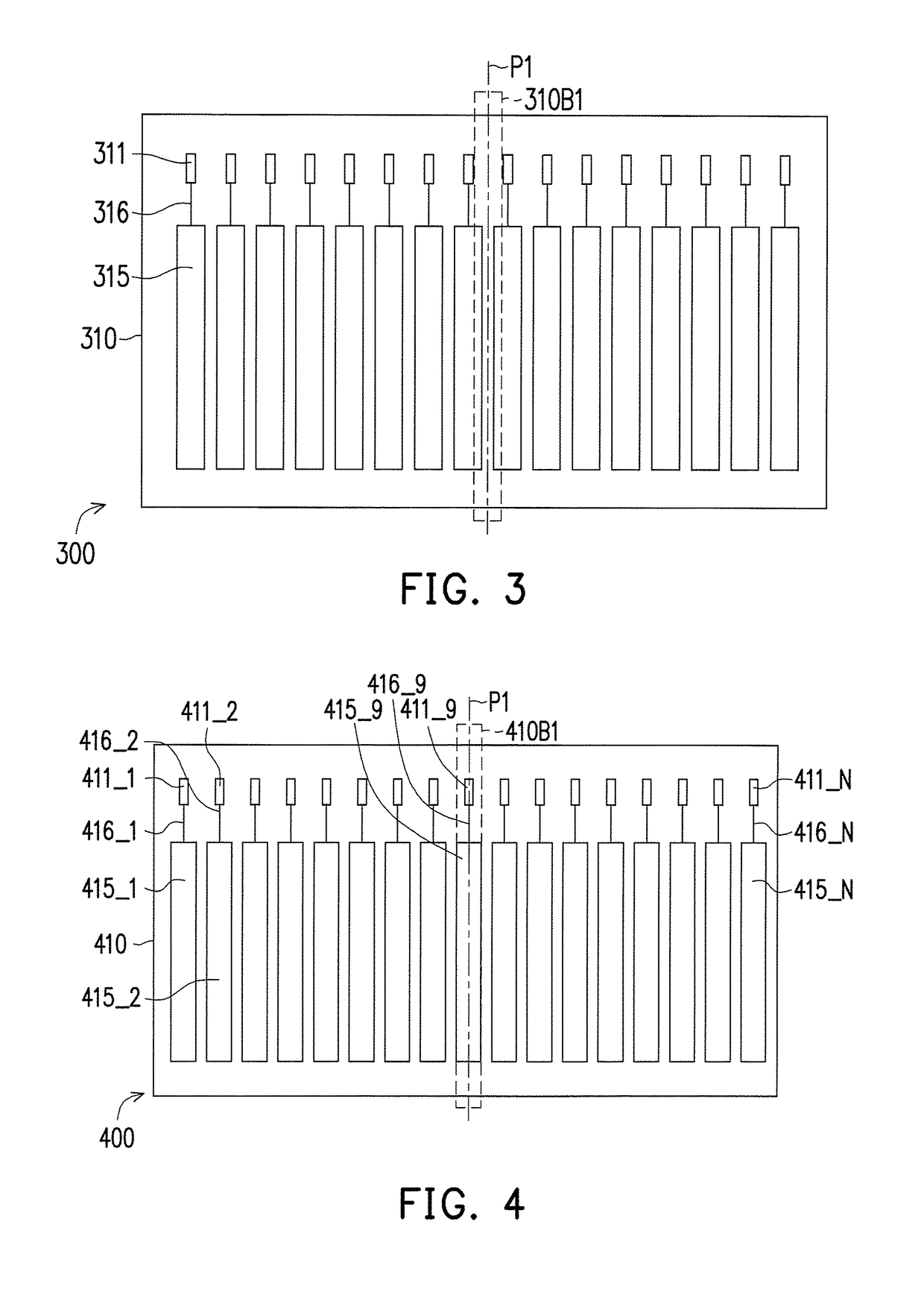

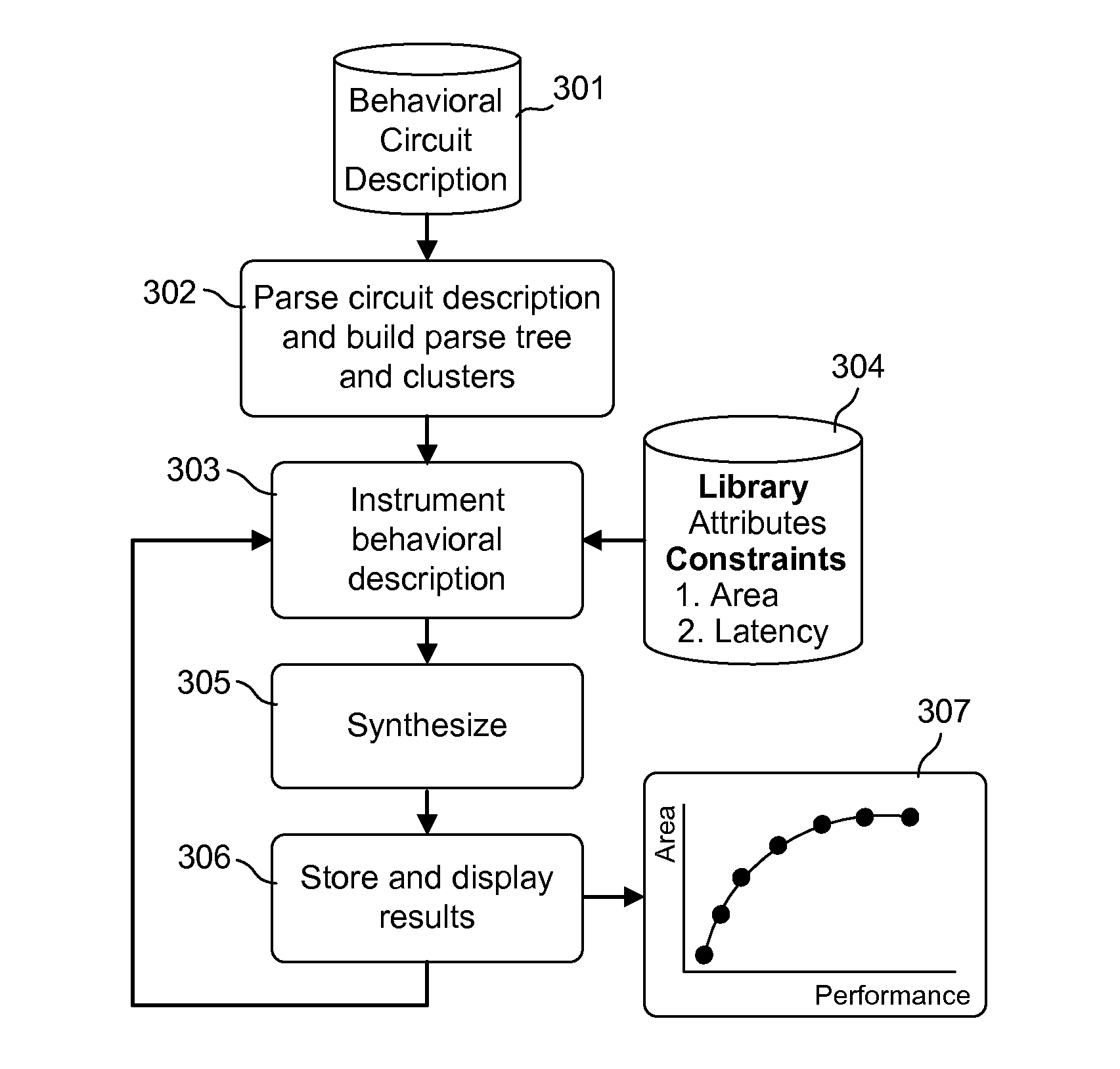

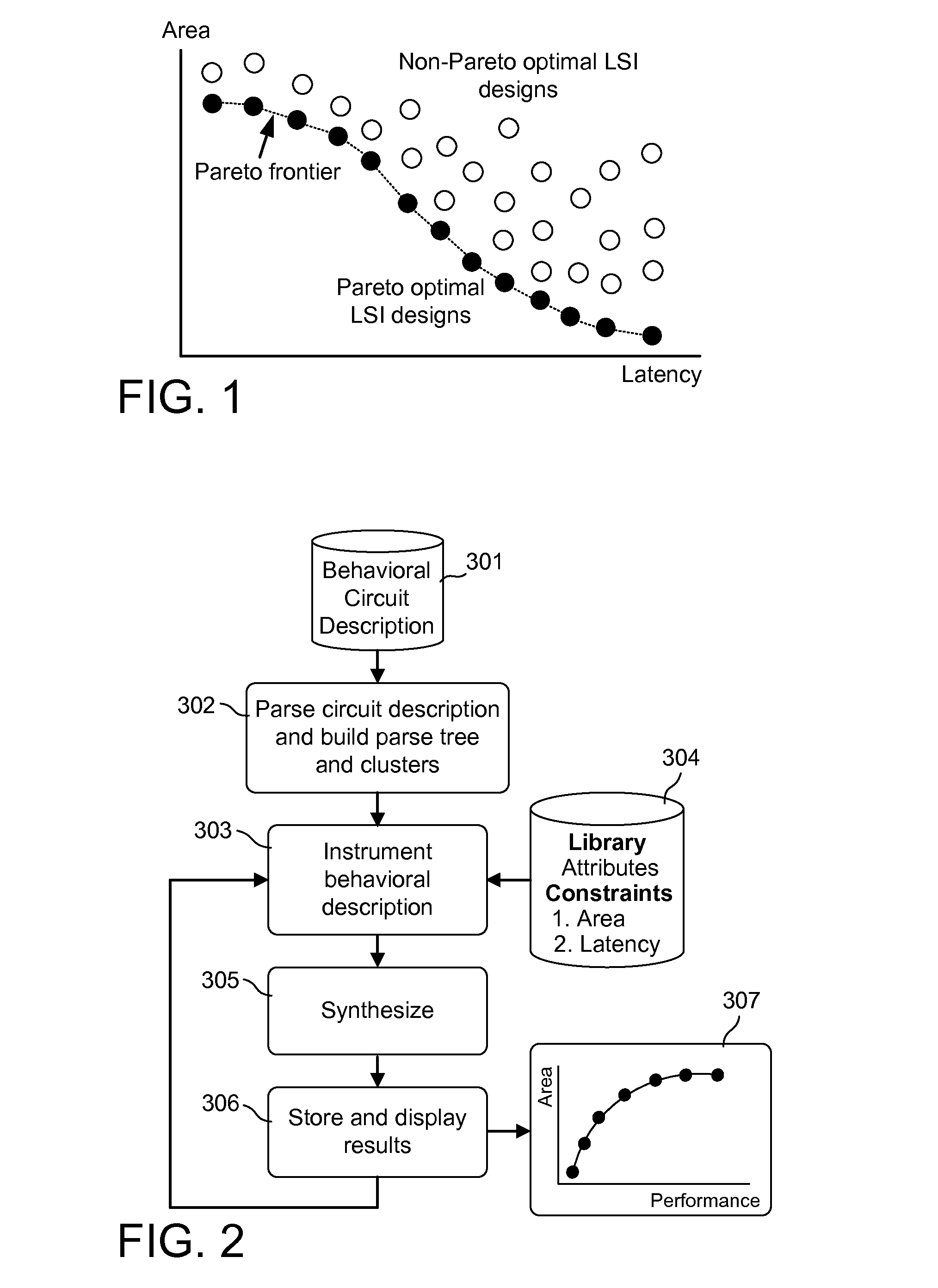

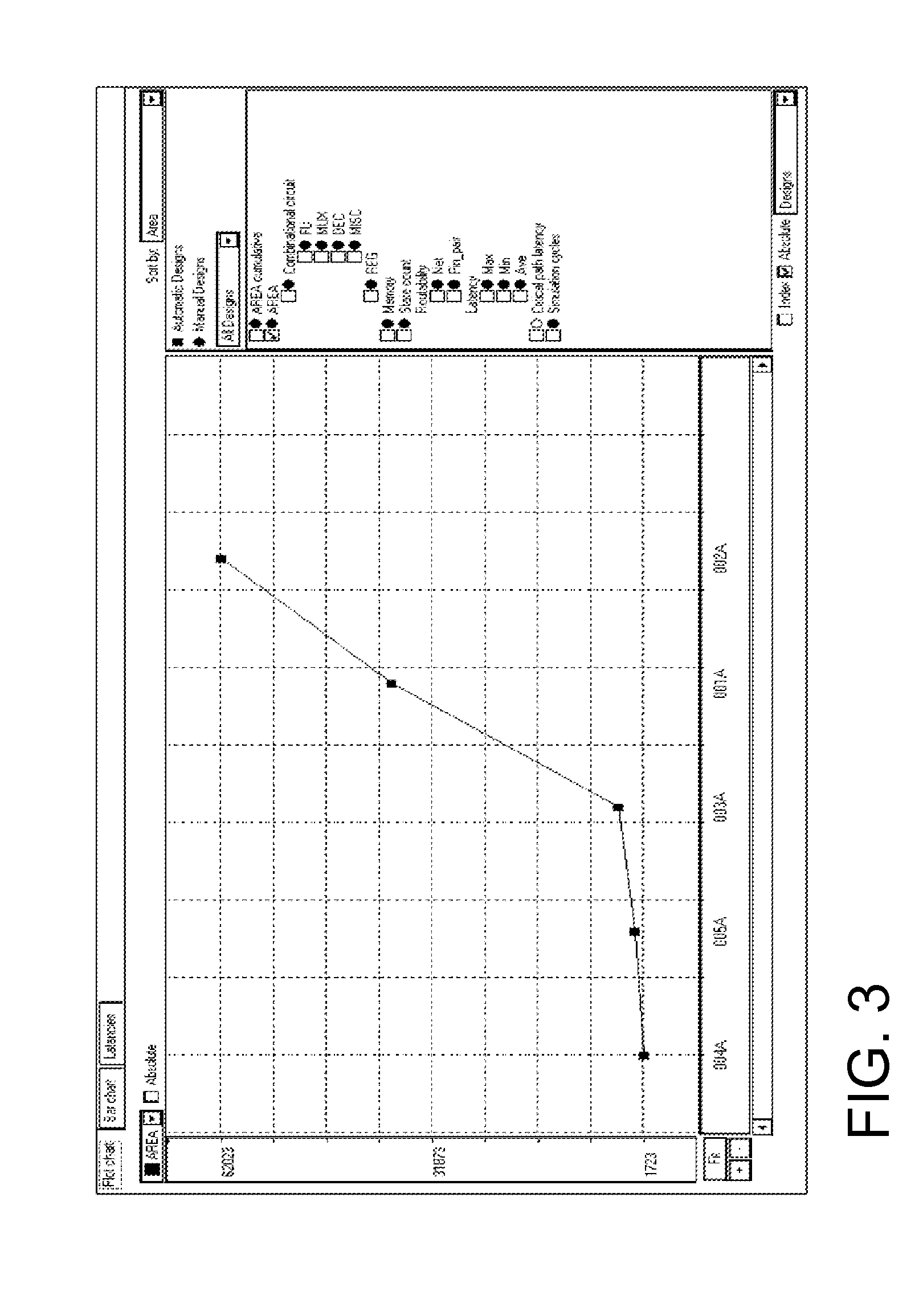

Method and apparatus for design space exploration acceleration

InactiveUS20130091482A1Accelerating design space searchAddressing slow performanceCAD circuit designMulti-objective optimisationTheoretical computer scienceDesign space exploration

A method for accelerating design space exploration of a target device when a behavioral description of the target device is given, includes: parsing the behavioral description to build a dependency parse tree; creating independent sets of clusters based on the dependency parse tree, each cluster being a set of a node or nodes of the dependency parse tree and independently explorable; exploring synthesizable operations of each cluster exhaustively in order to establish impact of each operation synthesized differently on a final circuit in designing of the target device; and combining attributes for the clusters to create designs with improved characteristics under constraints.

Owner:NEC CORP

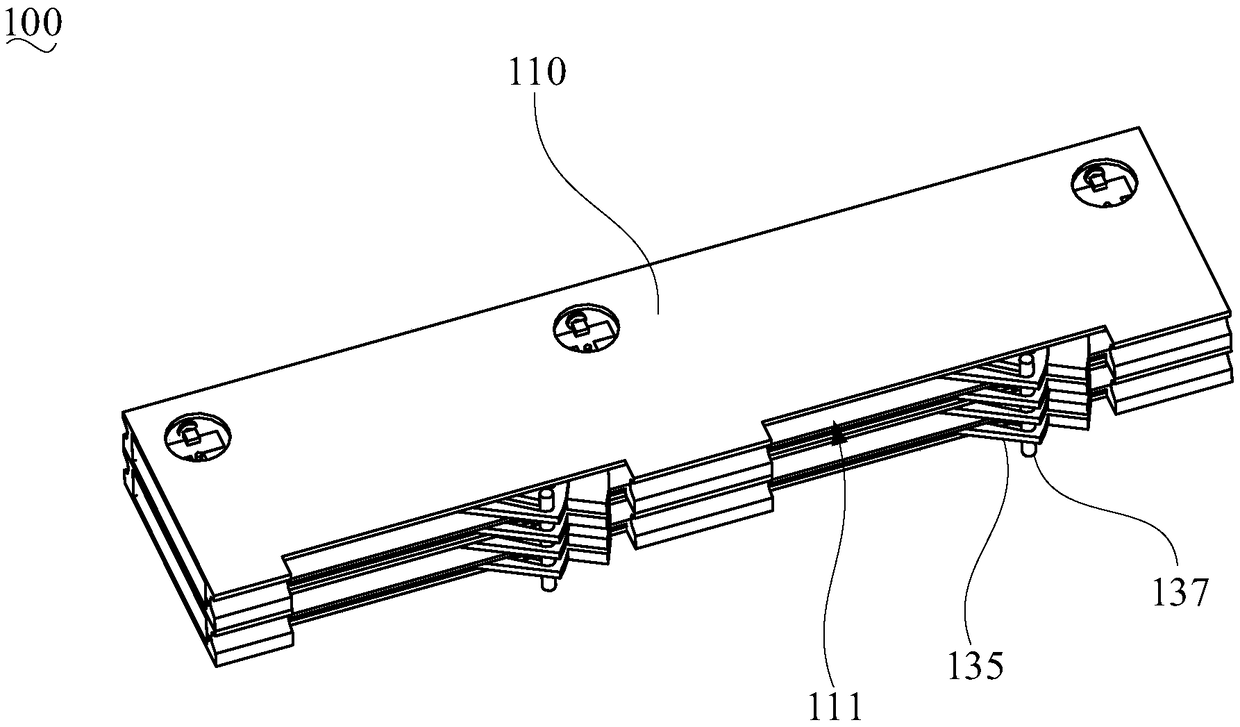

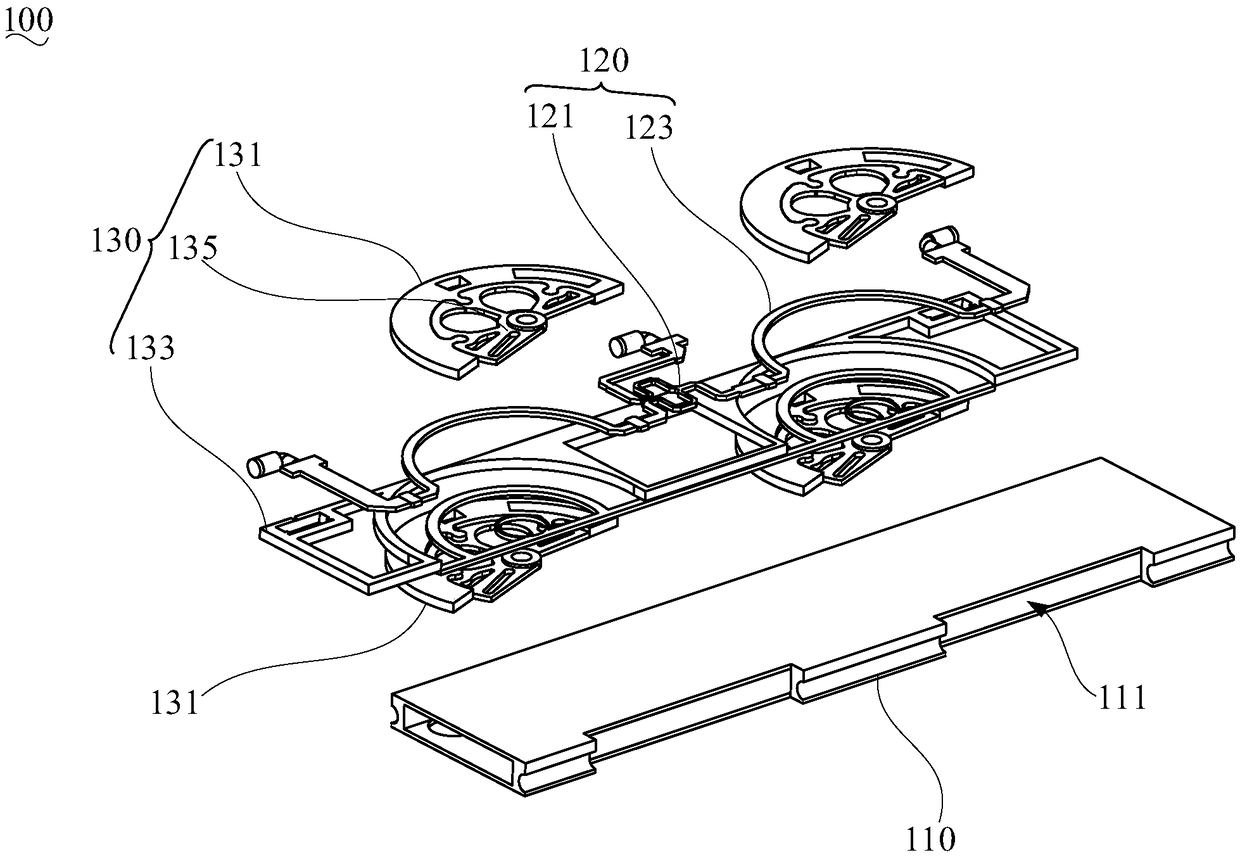

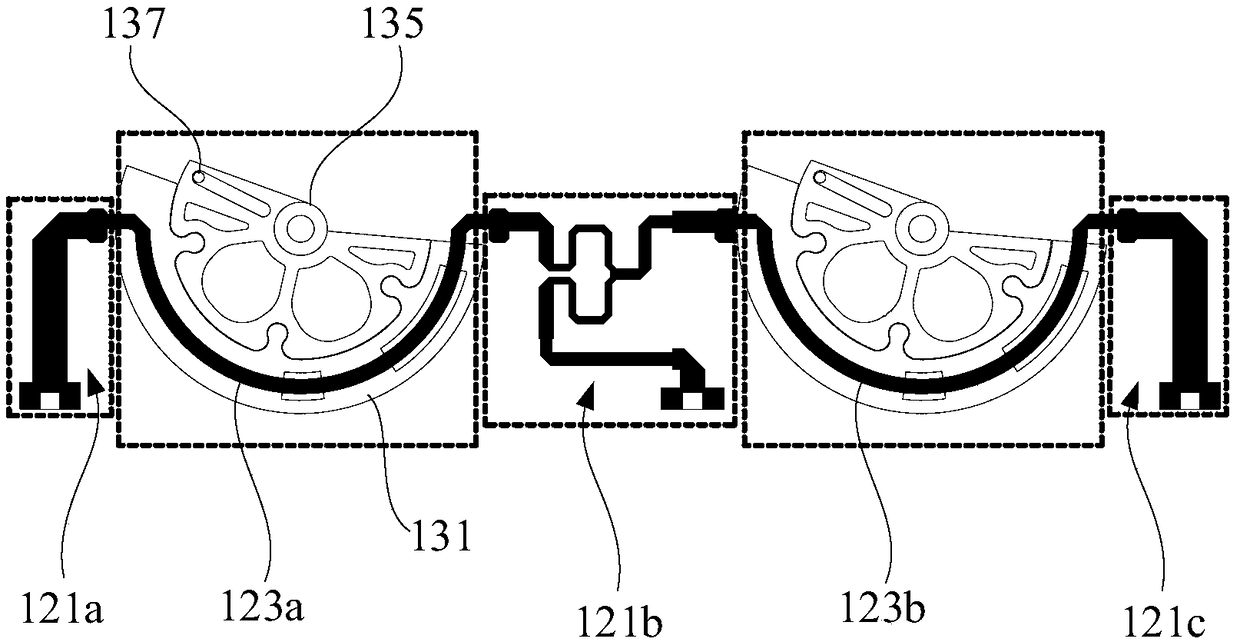

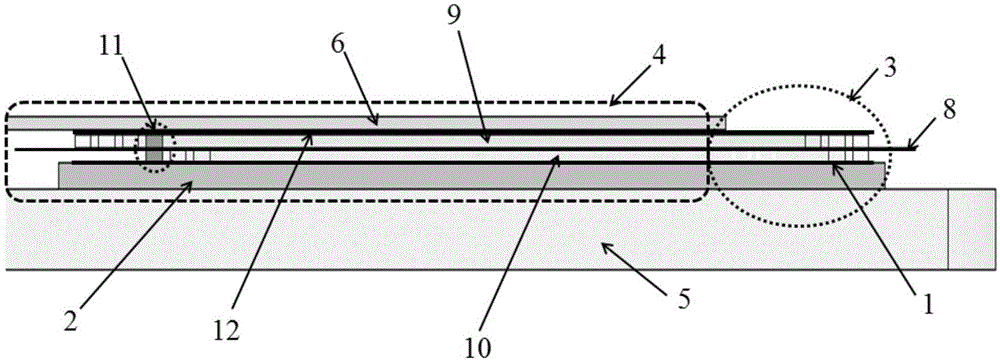

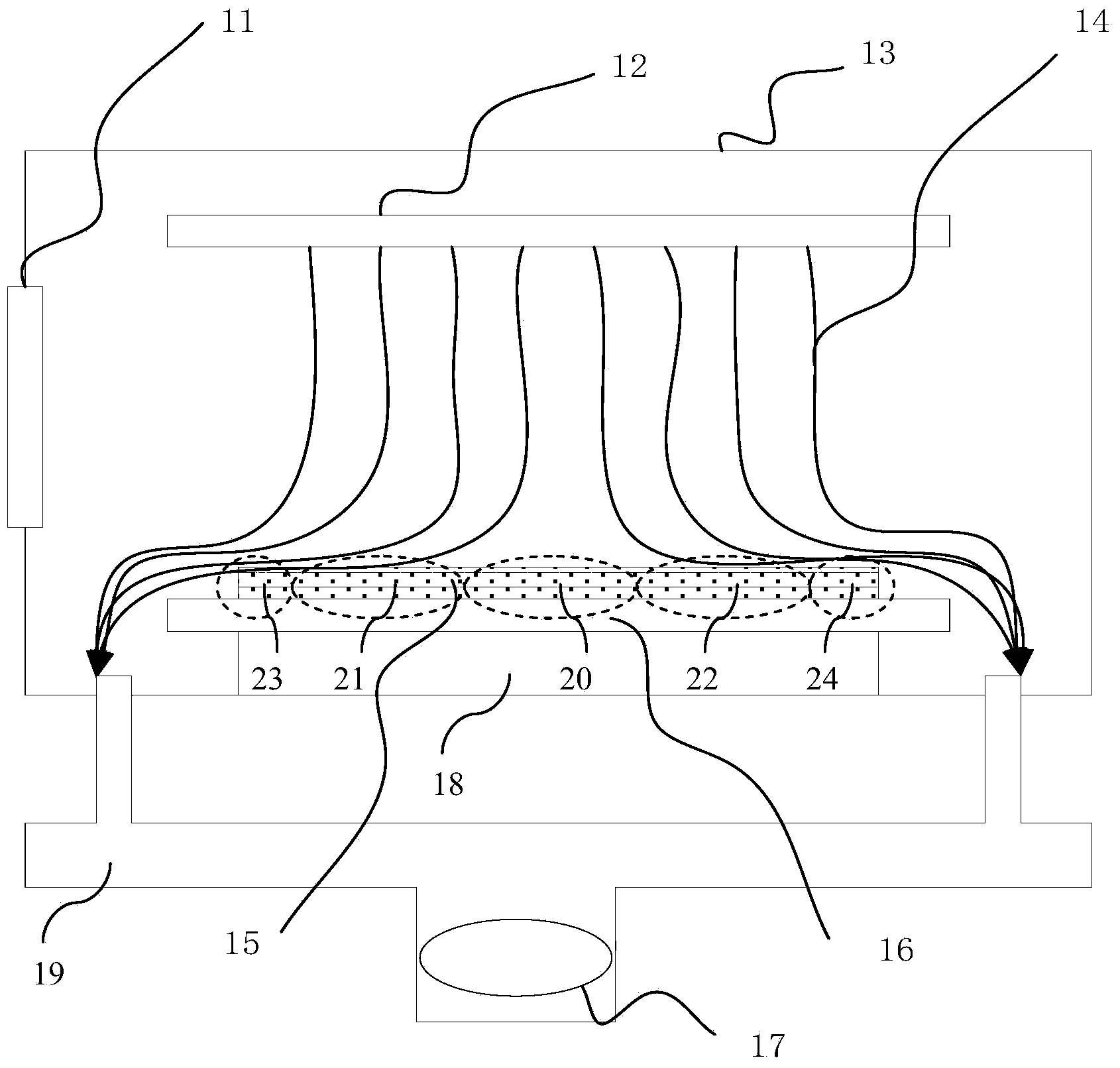

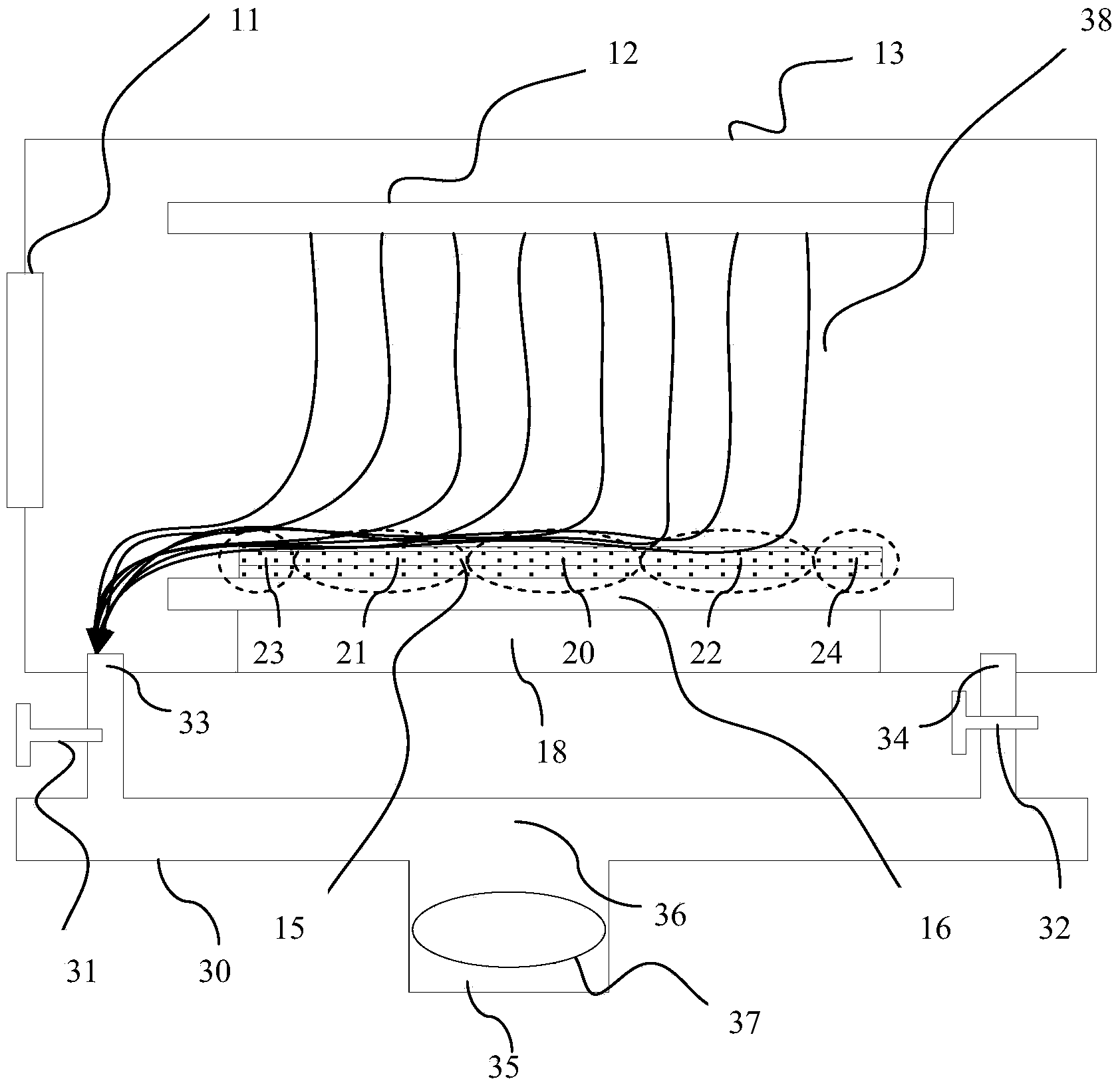

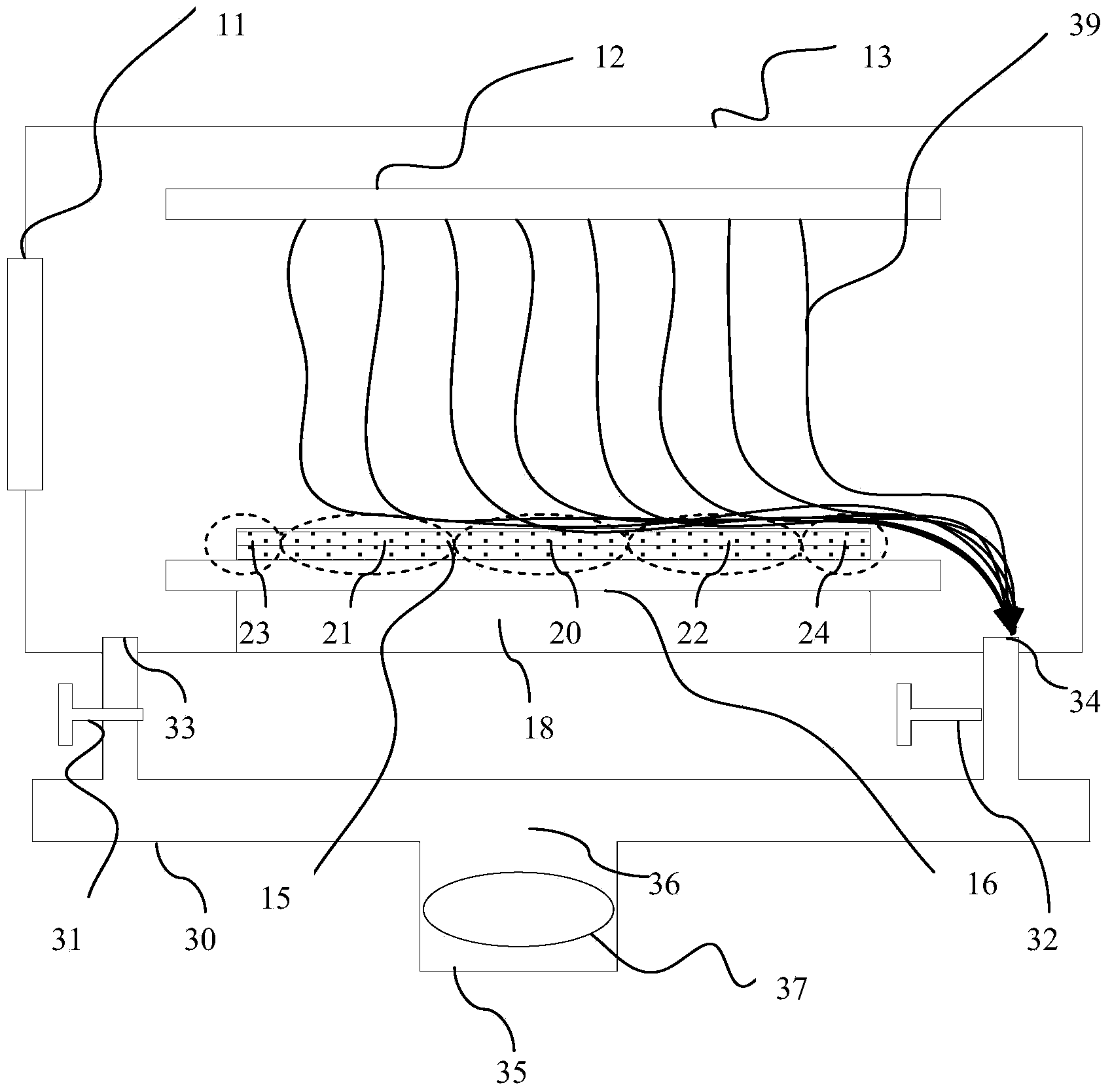

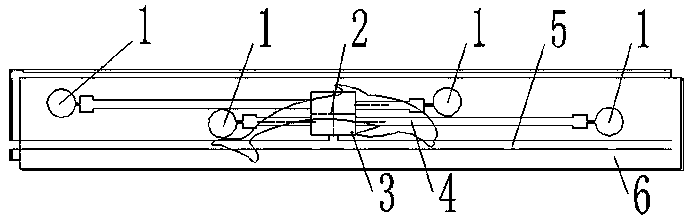

Dielectric sliding type phase shifter and base station antenna

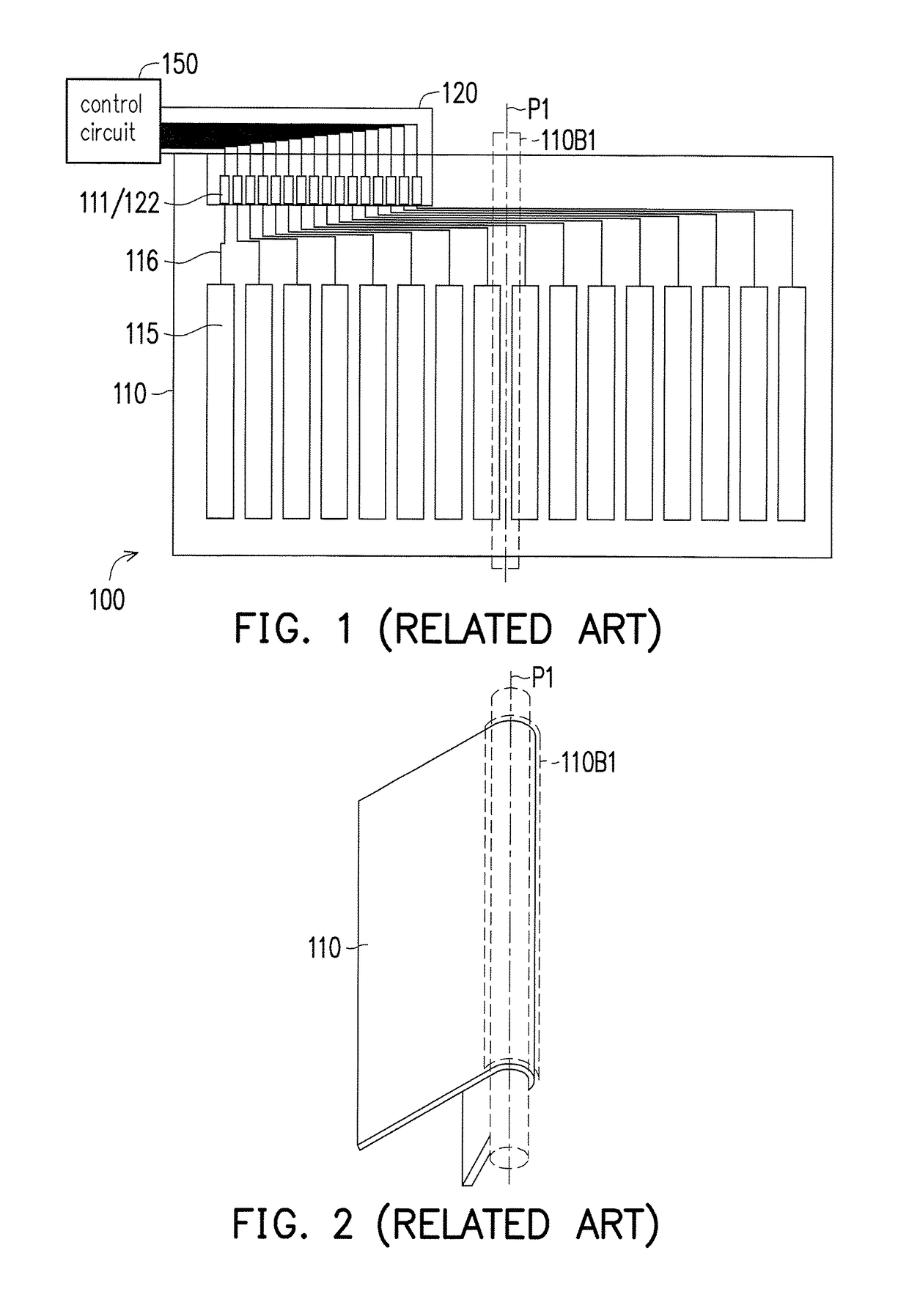

ActiveCN108879035ASimple structural designReduce design difficultyWaveguide type devicesAntennasDielectric plateEngineering

The invention discloses a dielectric sliding type phase shifter and a base station antenna. The dielectric sliding type phase shifter comprises a cavity, a feed network and a phase shifting unit. Thefeed network includes a functional circuit and phase shifting circuits. The surfaces of the phase shifting circuits are covered with dielectric plates, by rotating the dielectric plates, the length ofthe phase shifting circuits covered by the dielectric plates can be changed, and then the electrical length of a transmission line can be changed to realize phase adjustment. Furthermore, the phase shifting circuits and the dielectric plates are in an arc shape. Therefore, when the dielectric plates of the phase shifting units rotate around the axis passing through the center of the circle, the dielectric plates are limited within a circle range without exceeding the range of the corresponding phase shifting circuits. That is to say, the processes that the phase-shifting circuits realize phase adjustment are relatively independent. Therefore, functional circuits and phase shifting circuits can be designed independently, the design space of the circuit is greatly improved, the design difficulty of the phase shifter is greatly reduced, and the problem of limited design space of circuits in a traditional dielectric sliding type phase-shifter is solved.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

Card edge connector assembly

ActiveUS7074090B2Reduce abrasionReduce breakageEngagement/disengagement of coupling partsTwo-part coupling devicesShock resistanceFront edge

A card edge connector assembly includes a circuit board, a connector, an electrical card and a fixing structure. The connector is formed on the circuit board, the front rim of the electrical card is inserted into the insertion slot of the connector. The fixing structure has an elastic element having a fixing portion positioned on the circuit board. Two relating opposing sides of the fixing portion extends two elastic arms whose free ends form a beveled edge and a clasp portion, and define positioning slots on the rear rim of the electrical card. The length of the elastic arm increases in such a way that the elasticity of the elastic arm becomes greater so as to prevent the elastic arm abrading and breaking to ensure the positioning function and enhance the shock-resistance.

Owner:MOLEX INC

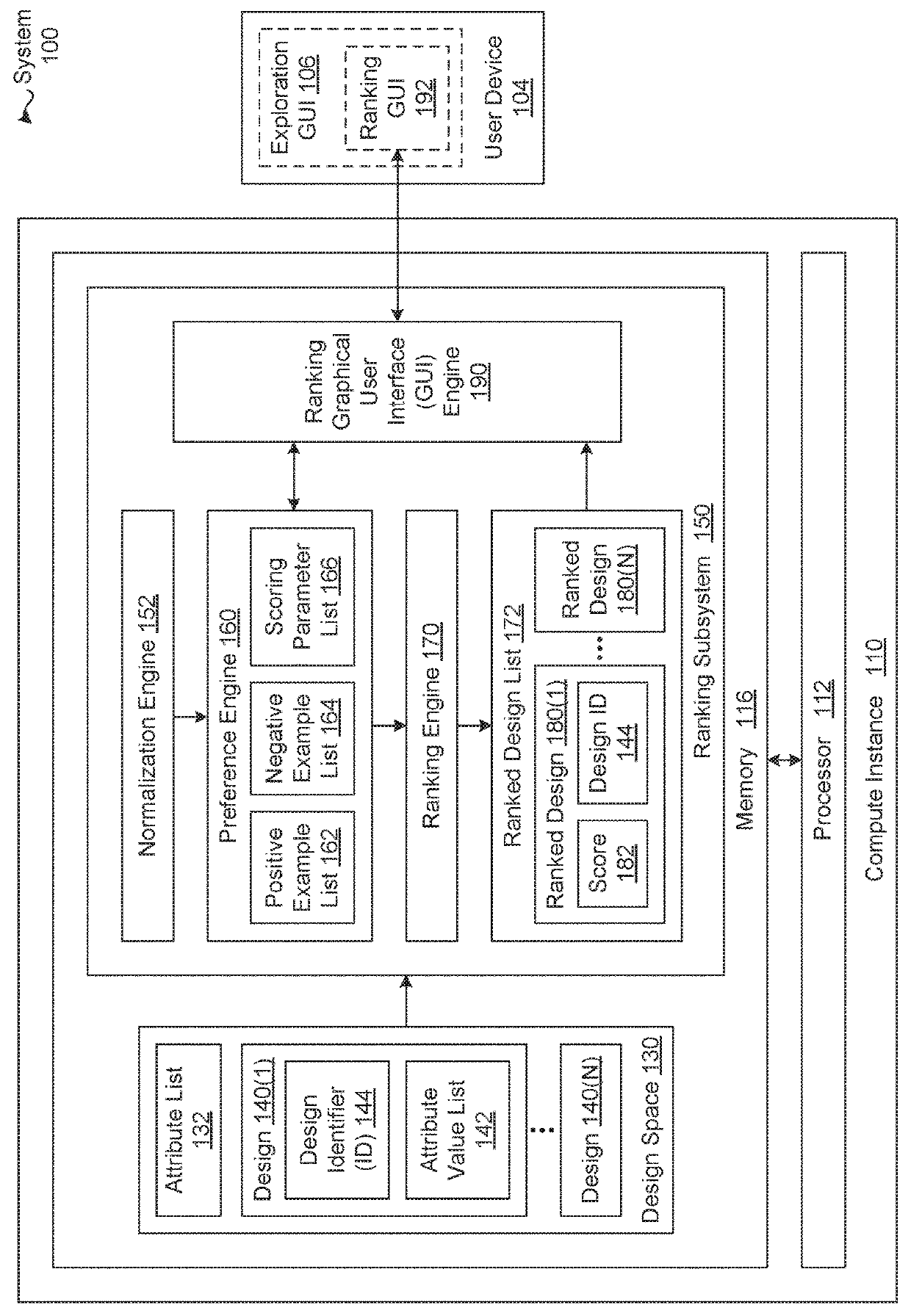

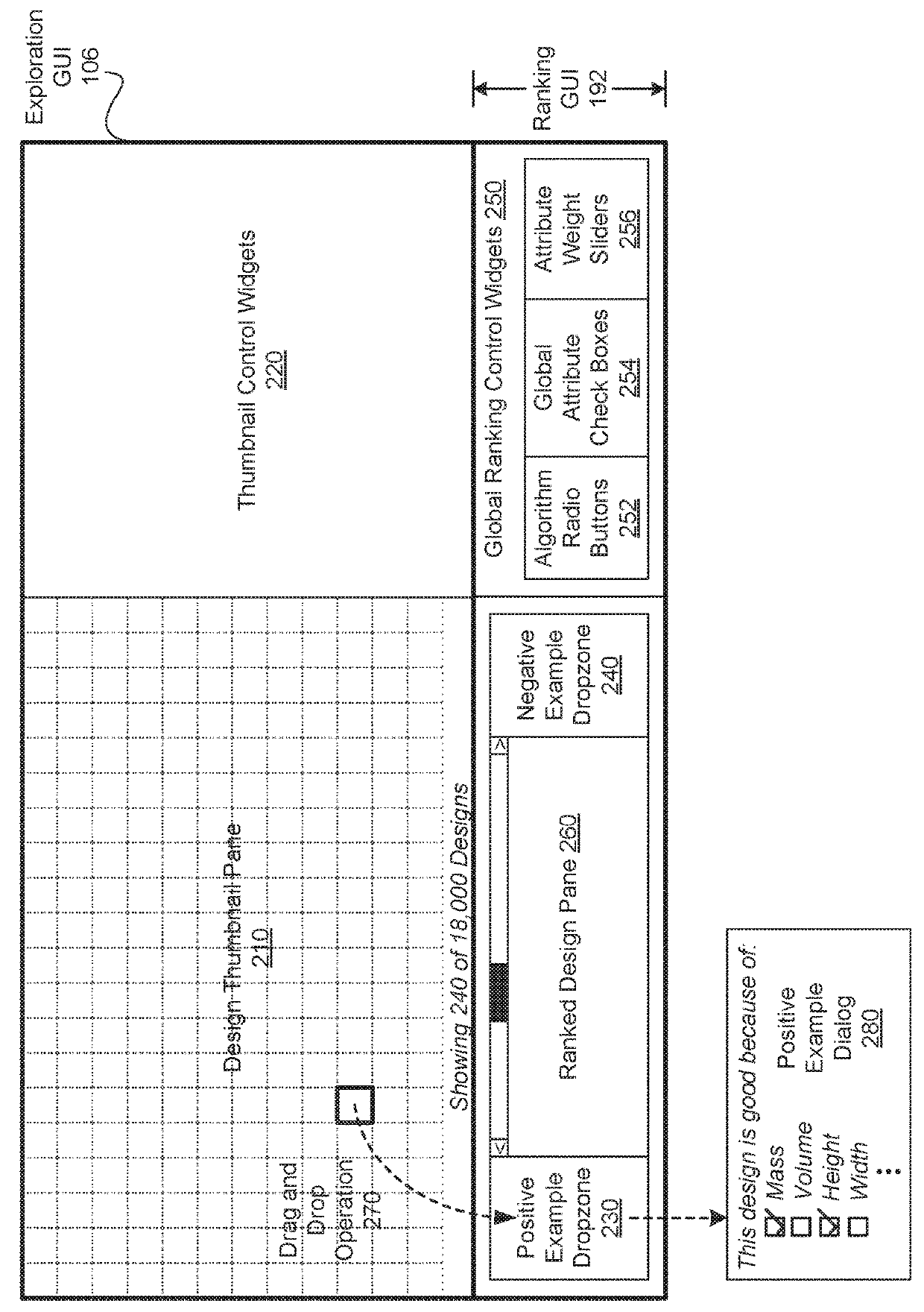

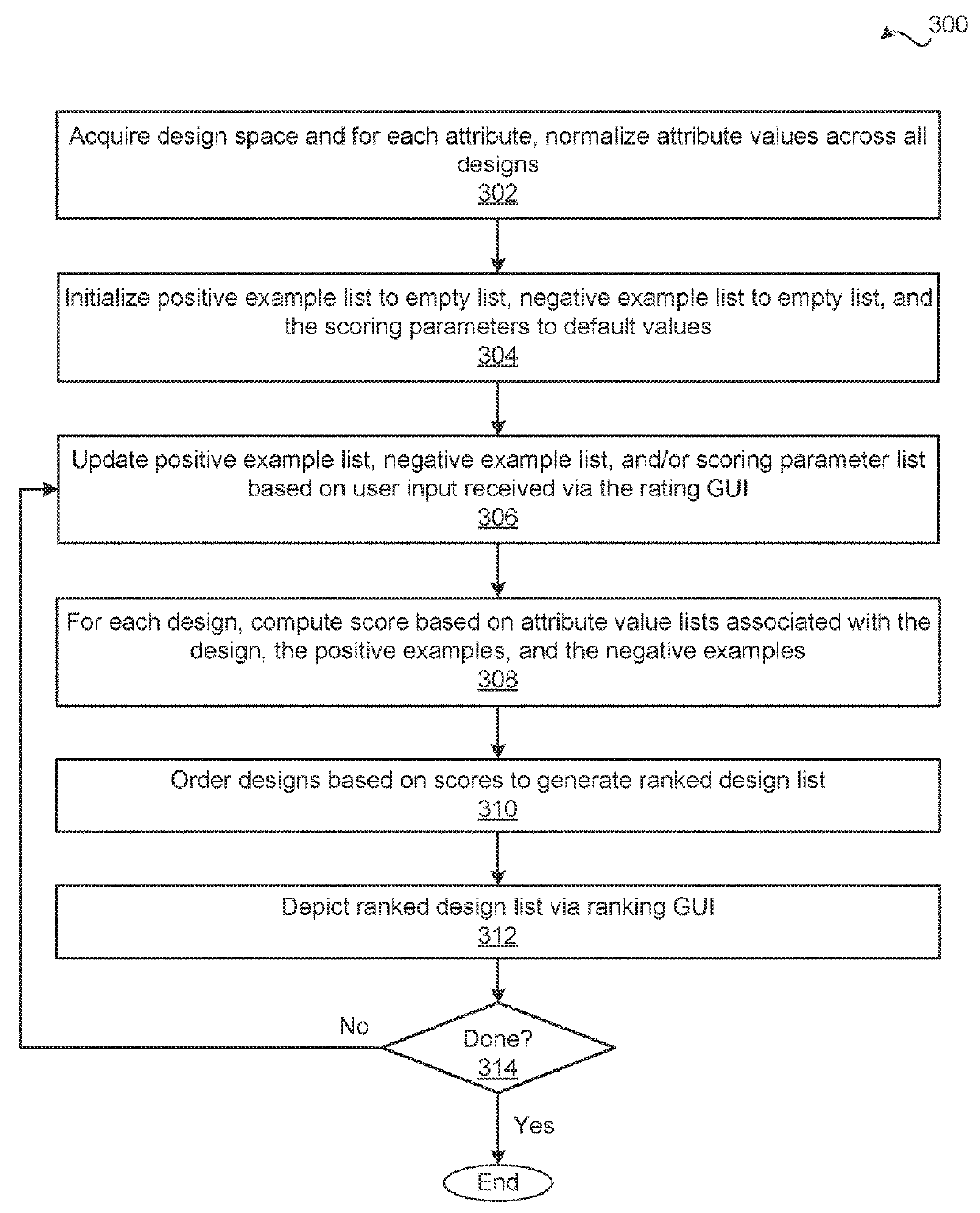

Example-based ranking techniques for exploring design spaces

ActiveUS20180267676A1Easy to exploreEfficiently and subjectively evaluateDigital data information retrievalConstraint-based CADGraphicsGraphical user interface

In various embodiments, a ranking application automatically ranks designs included in a design space based on user preference(s). The ranking application determines that a first design included in the design space is a first positive example of user preference(s). The ranking application then computes a score associated with a second design that is also included in the design space based on a first attribute value and a second attribute value. The first attribute value is associated with both the first design and an attribute and the second value is associated with both the second design and the attribute. Subsequently, the ranking application orders the designs based on the first score and a second score associated with the second design to generate a ranked list of designs. The ranking application then displays the ranked list of designs via a graphical user interface to facilitate exploration of the design space.

Owner:AUTODESK INC

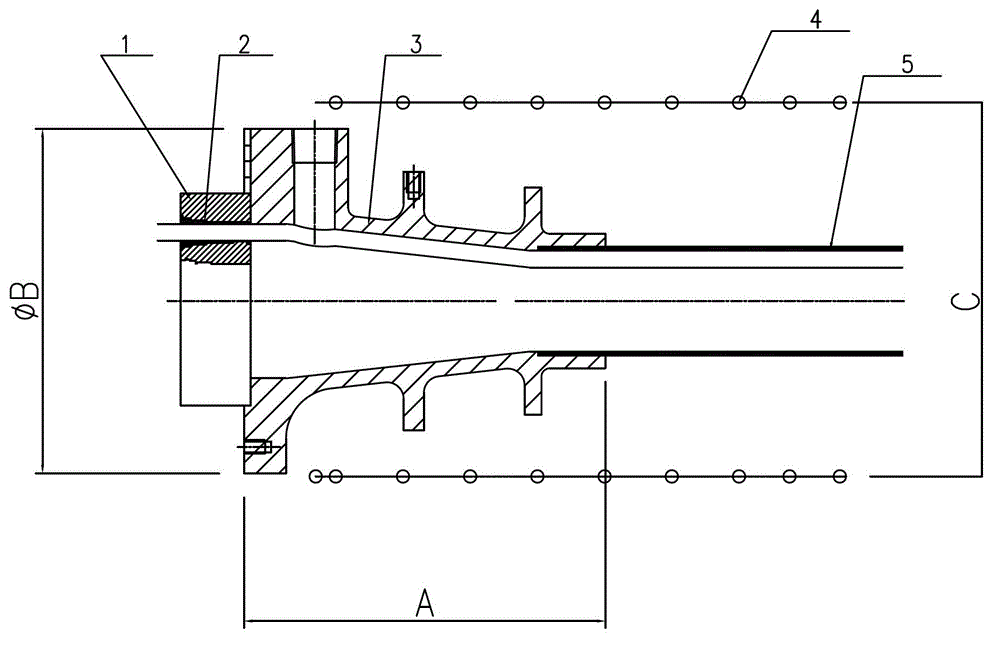

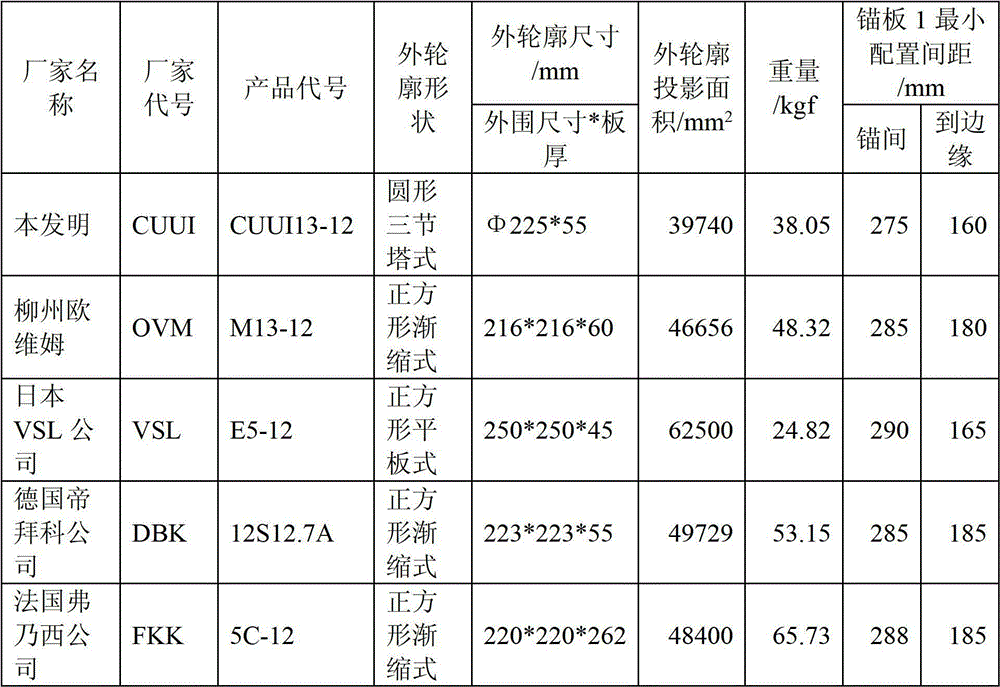

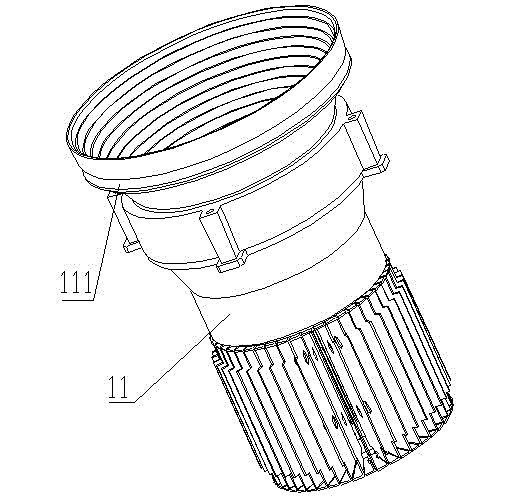

Anchor system for fixing steel strand in pre-stressed structure

InactiveCN102979253ACompressed footprintCompact footprintBridge structural detailsBuilding reinforcementsReinforced concreteSheet steel

The invention discloses an anchor system for fixing a steel strand in a pre-stressed structure. The anchor system comprises an anchor board, an anchor bearing plate, below-anchor spiral ribs and clamping pieces, wherein a main body of the anchor bearing plate is in a cylindrical form and gradually contracts from outside to inside; three round pressure-bearing steel boards are adhered to the outer side of the cylindrical main body at certain intervals; the sizes of the three-order steel boards are gradually reduced from outside to inside; and the middle part of the cylindrical main body is used for threading of pre-stressed steel. The anchor bearing plate of the anchor system adopts the form that the three-order round pressure-bearing boards are arranged along depth, a first-order pressure-bearing board shares more than a half of concentrated force, a second-order pressure-bearing board and a third-order pressure-bearing board share about 2 / 3 and 1 / 3 of the residual concentrated force, and the concentrated force of the anchor board is uniformly transmitted to the deep part of concrete below an anchor, so that not only can partial pressure stress under the anchor be prevented from being too concentrated, but also the limitation effect of the below-anchor spiral ribs can be effectively improved. Therefore, the occupied area and the space of the anchor bearing plate can be greatly reduced, and a design space and a construction property for anchor configuration in beam-column node positions of a reinforced concrete frame can be greatly enlarged and improved.

Owner:DALIAN NATIONALITIES UNIVERSITY

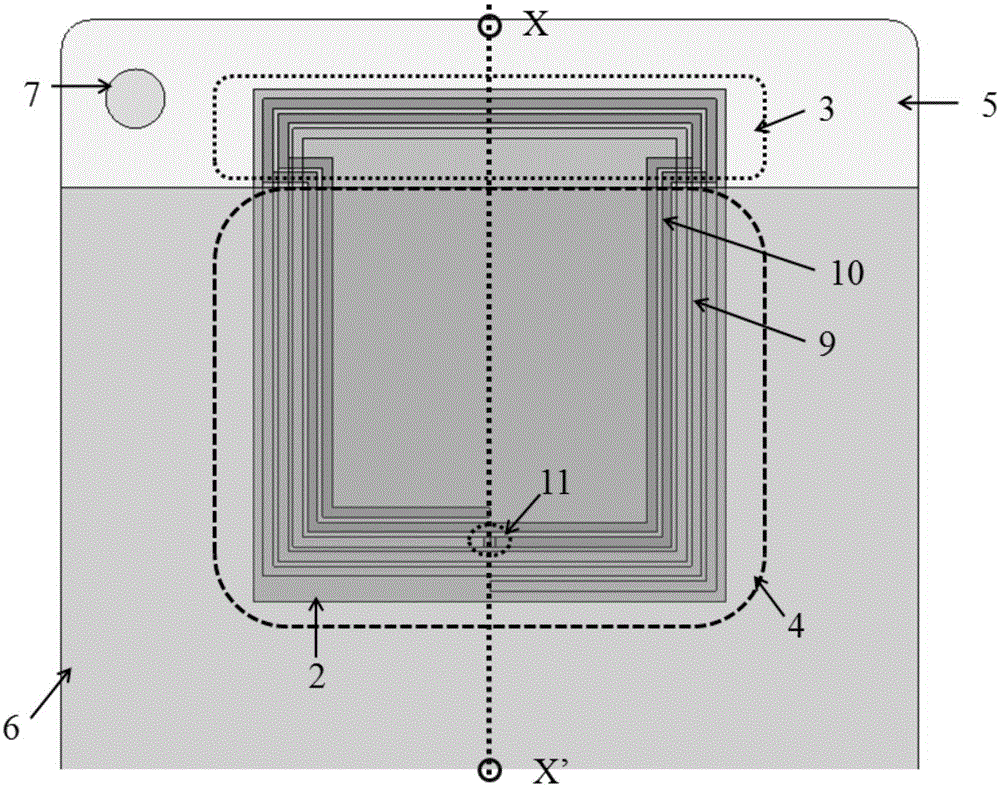

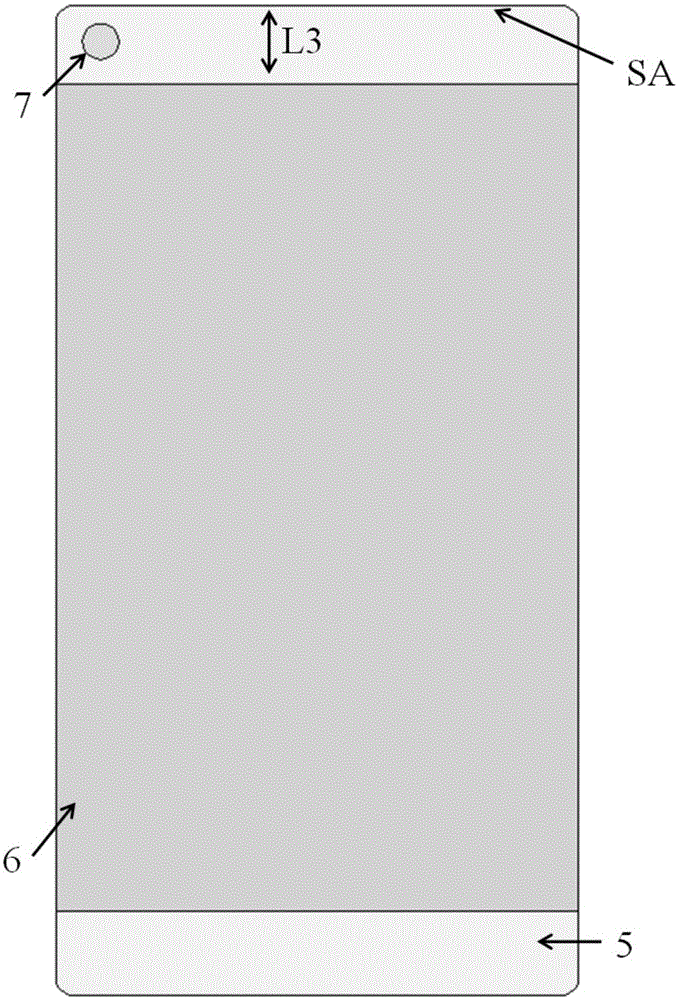

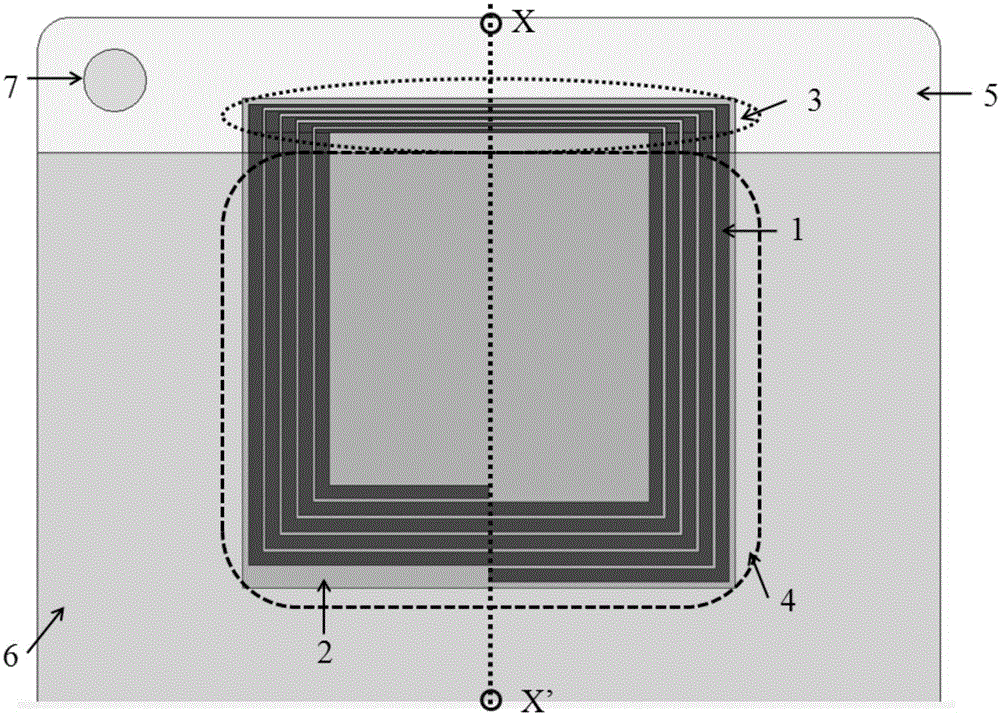

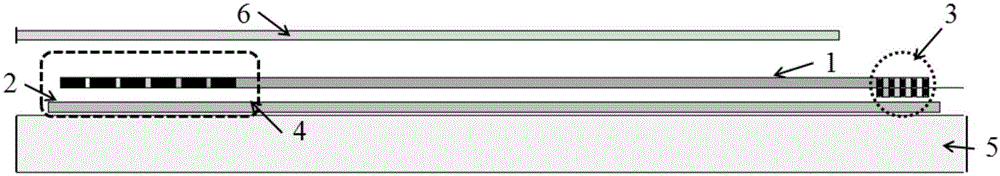

Near-field communication antenna device

ActiveCN105098324ARealize multi-turn windingImprove Radiation PerformanceLoop antennas with ferromagnetic coreAntenna supports/mountingsElectrical conductorDevice form

The invention provides a near-field communication antenna device, and belongs to the field of wireless communication. The antenna device is an antenna device formed in electronic equipment. The antenna device comprises a shell conductor layer, a first insulating layer, a first coil conductor, a flexible substrate, a second coil conductor, a second insulating layer and a magnetic material layer. The first coil conductor and the second coil conductor are respectively arranged at the two sides of the flexible substrate and connected via a through hole. When the first coil conductor is overlooked, the first coil conductor is divided into a first area in which the conductive wires of the first coil conductor and the second coil conductor are completely overlapped or partially overlapped; and a second area in which the conductive wires of the first coil conductor and the second coil conductor are not overlapped completely or not overlapped partially. Insulating processing is performed on the surfaces of the coil conductors of the two sides of the flexible substrate. The shell conductor layer completely covers the second area and does not cover the first area completely. Long-distance communication is realized by the antenna device without damaging the electronic equipment shell metal structure; and the size of the antenna device is reduced on the basis of guaranteeing antenna communication distance.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Hot forming method and hot forming mould

The invention discloses a hot forming method and a hot forming mould. The hot forming method includes providing the hot forming mould which is provided at least with a first portion and a second portion long the horizontal direction; guiding a heated austenitized steel plate into the hot forming mould to be subjected to forming process; cooling the first portion of the hot forming mould at a first cooling rate and cooling the second portion of the hot forming mould at a second cooling rate, wherein the first cooling rate is different from the second cooling rate, accordingly, an integrally formed component with changed transverse strength is formed in the hot forming mould. The structure of the hot forming mould is simple, components with diversified originations and different strength distribution can be obtained through simple process, performances of different positions of the components can have great differences, so that requirements of different occasions can be satisfied. Due to the hot forming method, not only the design space of steel plate materials can be improved, but also parameter setting is simplified, and the production cost is reduced.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

Tear-resistant antistatic EVA (ethylene-vinyl acetate copolymer) foamed shoe material

The invention discloses a tear-resistant antistatic EVA (ethylene-vinyl acetate copolymer) foamed shoe material which is prepared from the following raw materials in parts by weight: 45-55 parts of EVA, 25-35 parts of polyolefin block copolymer, 10-15 parts of ethylene-acrylic acid copolymer, 6-12 parts of calcium carbonate, 0.5-1 part of stearic acid, 1.5-2.5 parts of zinc stearate, 0.5-1.5 parts of magnesium oxide, 0.6-1.2 parts of dicumyl peroxide, 2-2.5 parts of azobisformamide and 2-3 parts of antistatic agent. Compared with the existing EVA foamed shoe material, the tear-resistant antistatic EVA foamed shoe material disclosed by the invention has the original physical properties of the EVA foamed material, overcomes the defects of high tear tendency and high damage tendency in the traditional EVA foamed shoe, increases the design space for various shoes, enhances the antistatic property of the shoe sole, and has very good use effect.

Owner:SUZHOU JINGRO TECH

Standard cells having transistors annotated for gate-length biasing

InactiveUS20130014073A1Reduce impactImpairing time delay performance only linearlyCAD circuit designSoftware simulation/interpretation/emulationSemiconductor chipEngineering

A standard cell library is disclosed. The standard cell library contains cells wherein at least one transistor in at least one cell is annotated for gate length biasing. Gate length biasing includes the modification of the gate length, so as to change the speed or power consumption of the modified gate length. The standard cell library is one used in the manufacturing of semiconductor devices (e.g., that result as semiconductor chips), by way of fabricating features defined on one or more layouts of geometric shapes. The annotations serve to identify which ones of the transistor gate features are to be modified before using the geometric shapes for manufacturing the semiconductor device.

Owner:RPX CORP

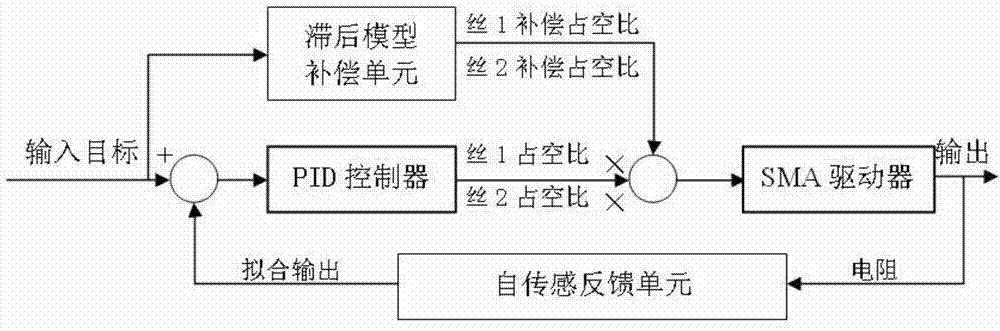

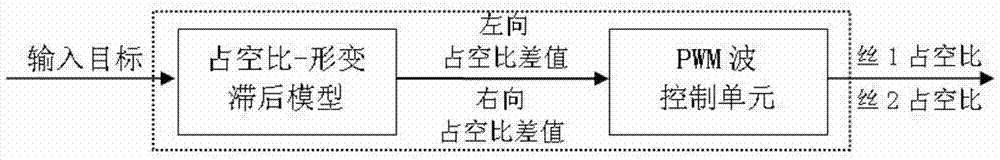

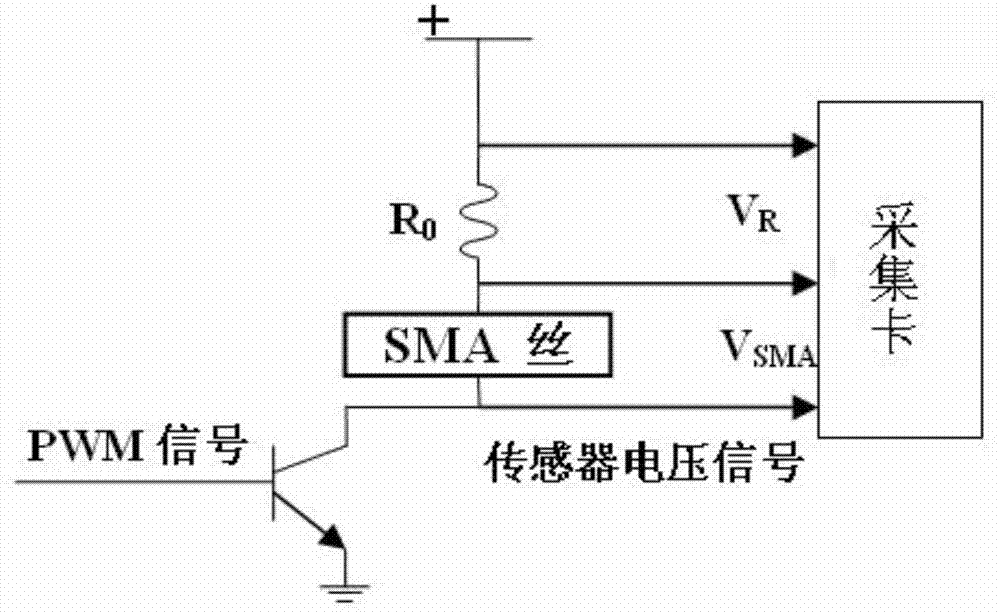

Self-feedback drive control system of double shape memory alloy wires and testing platform of drive control system

InactiveCN103076739AIncrease design spaceFlexible operationDiagnosticsControllers with particular characteristicsElectrical resistance and conductanceProportion integration differentiation

The invention discloses a self-feedback drive control system of double shape memory alloy wires and a testing platform of the drive control system. The drive control system comprises an SMA (Shape Memory Alloy) driver, wherein the output end of the SMA driver is used for outputting driving voltage and / or current to a first SMA wire and a second SMA wire, a PID (Proportion Integration Differentiation) controller is connected to the input end of the SMA driver, the PID controller is used for receiving input target position information and outputting voltage and / or current duty cycle signals of the first SMA wire and the second SMA wire to the SMA driver, a self-sensing feedback unit is connected between the output end of the SMA driver and the input end of the PID controller, and the self-sensing feedback unit is used for feeding displacement information, resistance information and force information back to the input end of the PID controller. The self-feedback drive control system and the testing platform thereof disclosed by the invention are simple in structure, small in size and free of an external sensor and have the advantages of realizing driving and executing integration actually, broadening the design space of a minimally invasive surgery instrument and providing a feasible scheme for a dedicated robot for single incision surgery.

Owner:BEIHANG UNIV

Near-field communication antenna device

ActiveCN105048061AExcellent designIncrease design spaceAntenna supports/mountingsRadiating element housingsMobile electronicsNear field communication

The invention belongs to the field of wireless communication and relates to an antenna device used in a short-distance wireless communication system. The antenna device is the antenna device formed in mobile electronic equipment, and comprises a coil conductor, a flexible substrate, a magnetic material and a housing conductor layer, wherein the coil conductor is an annular or helical coil employing a winding center part as a coil opening part; the coil conductor and the flexible substrate which is attached to the coil conductor are assembled on the surface of a magnetic sheet material; the coil conductor is shielded and divided into two areas by the housing conductor layer; the first area is a non-shielding part of the housing conductor layer, namely an actual magnetic link coupling part of the antenna; a narrow linewidth design is adopted by the coil conductor of the part or the narrow linewidth design is mainly adopted; a dual-conductor layer parallel design is adopted; the second area is a shielding part of the housing conductor layer; and a wide line design is adopted by the coil conductor of the area. The antenna device has the beneficial effects that the structural integrity of the metal part of a mobile equipment housing is not destroyed; the occupied space is small; and the performance is high.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Dry etching equipment and method thereof

ActiveCN104022006AImprove uniformityEasy to manufactureElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringOperation mode

The invention discloses a set of dry etching equipment which comprises an etching chamber and an air exhausting system that is arranged at the bottom of the etching chamber. The air exhausting system comprises the components of: an air exhausting channel which is provided with a plurality of air exhausting openings and air discharging openings, an air exhauster, and controllable valves which are respectively mounted on each air exhausting openings. The invention further discloses a dry etching method which comprises the following steps: placing a workpiece to be etched into a base station in the etching chamber; selecting an air exhausting mode according to a step to be performed, wherein the air exhausting modes comprises a circulating operation mode and a non-circulating operation mode; and performing the dry etching step when air exhausting is performing according to the circulating operation mode or the non-circulating operation mode. The dry etching equipment according to the invention has functions of: further improving homogeneity of the dry etching process, improving homogeneity in manufacture of an array substrate, improving product quality and yield rate, reducing restriction of process homogeneity to product design, and improving product design space.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

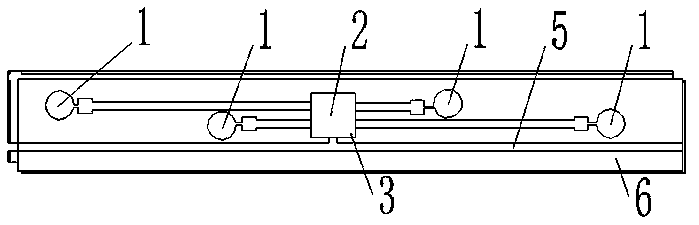

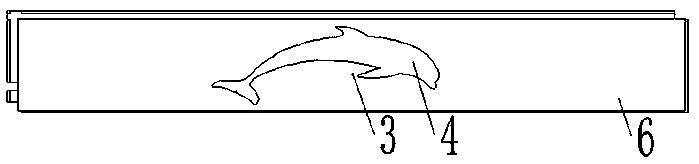

Intelligent luminous wood floor

PendingCN111236576AAdd funExtended service lifeCovering/liningsLighting elementsStructural engineeringDaylight

The invention belongs to the technical field of floor decoration, and relates to an in intelligent luminous wood floor. The intelligent luminous wood floor comprises a wood floor body, an upper grooveand a lower groove. A thin and narrow luminous pattern element is embedded in the upper groove, a sensor and a control circuit board are embedded in the lower groove, the upper groove and the lower groove communicate through a drill hole, the control circuit board in the lower groove is electrically connected with an illuminometer which is externally mounted and used for inducing sunlight intensity and a 5-24V power source, the lower groove is composed of a square groove in the middle and round grooves in the periphery, a circuit board is mounted in the square groove, sensors are mounted in the round grooves, and wire grooves are mounted between the round grooves and the square groove and communicate with an outer power line. A light-emitting unit is separated from a control part, the service life of the floor can be prolonged, the design space of the luminous pattern element is increased, the floor decoration property is improved, customer interest is increased, and the better marketprospect is achieved.

Owner:DAYA JIANGSU FLOOR +1

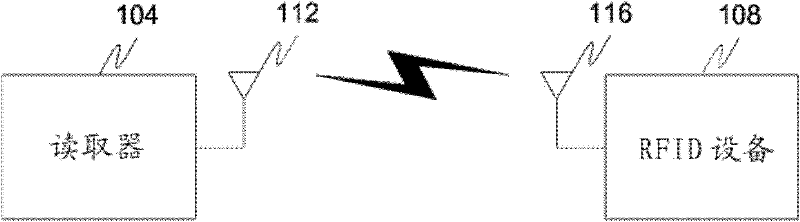

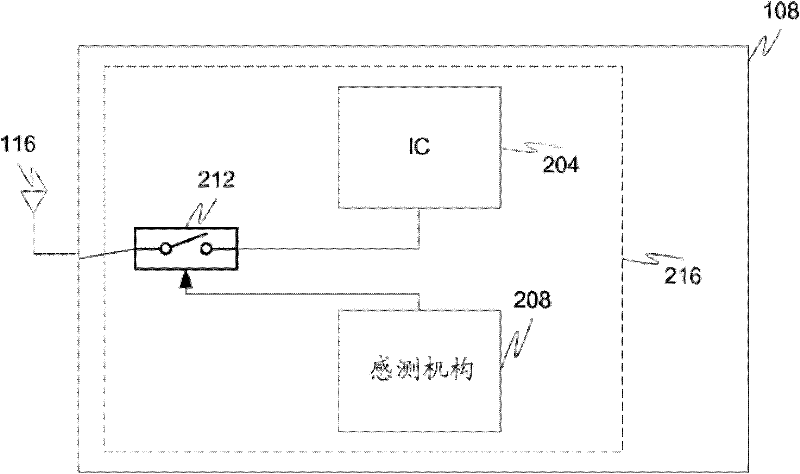

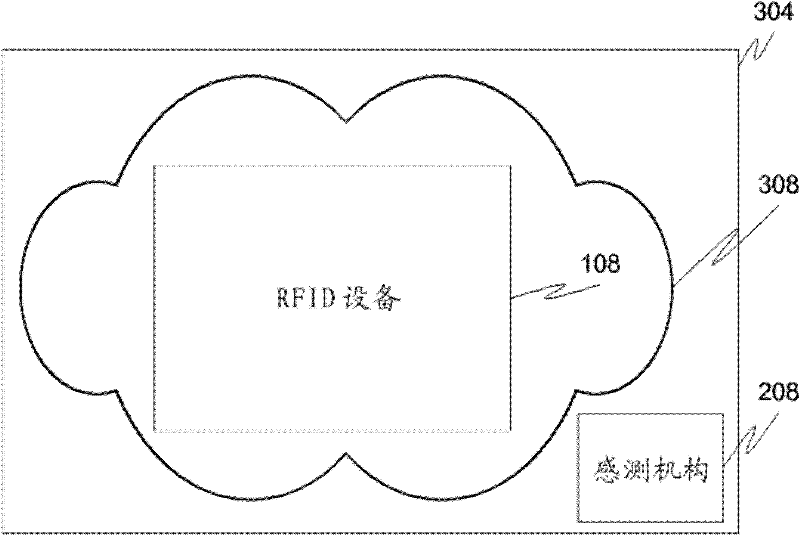

Directional sensing mechanism and communications authentication

InactiveCN102177535AImprove computing powerImprove perceptionUnauthorised/fraudulent call preventionDigital data processing detailsRf fieldMotion sensing

The present invention is directed toward an RFID device that includes a motion sensing mechanism. The motion sensing mechanism is adapted to sense motion of the RFID device and then selectively allow or restrict the RFID device's ability to transmit messages, which may include sensitive data, when the RFID device is placed in an RF field. Thus, the motion sensing mechanism is utilized to control access to data on the RFID device to only instances when the holder of the RFID device moves the RFID device in a predefined sequence of motion(s).

Owner:ASSA ABLOY AB

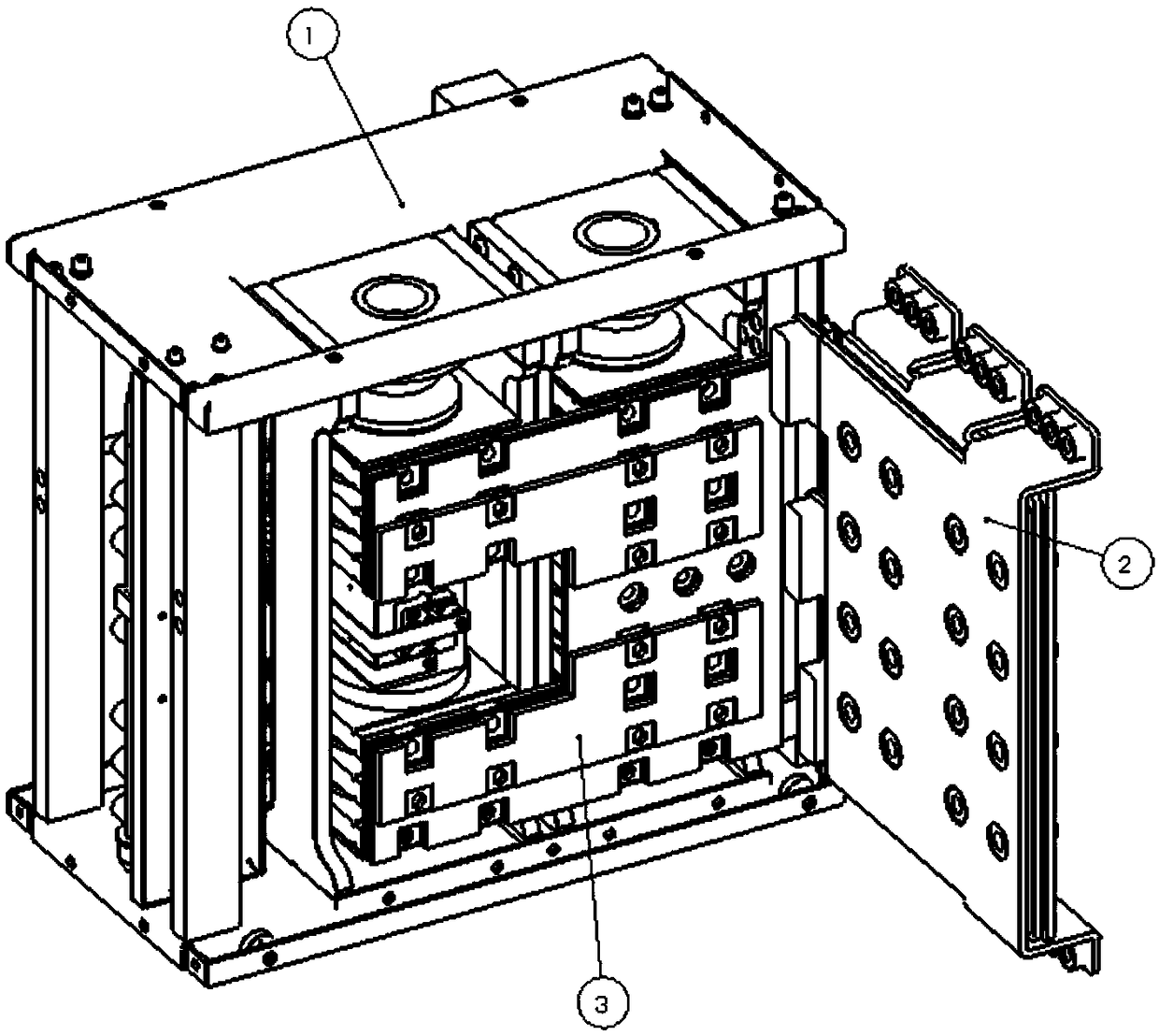

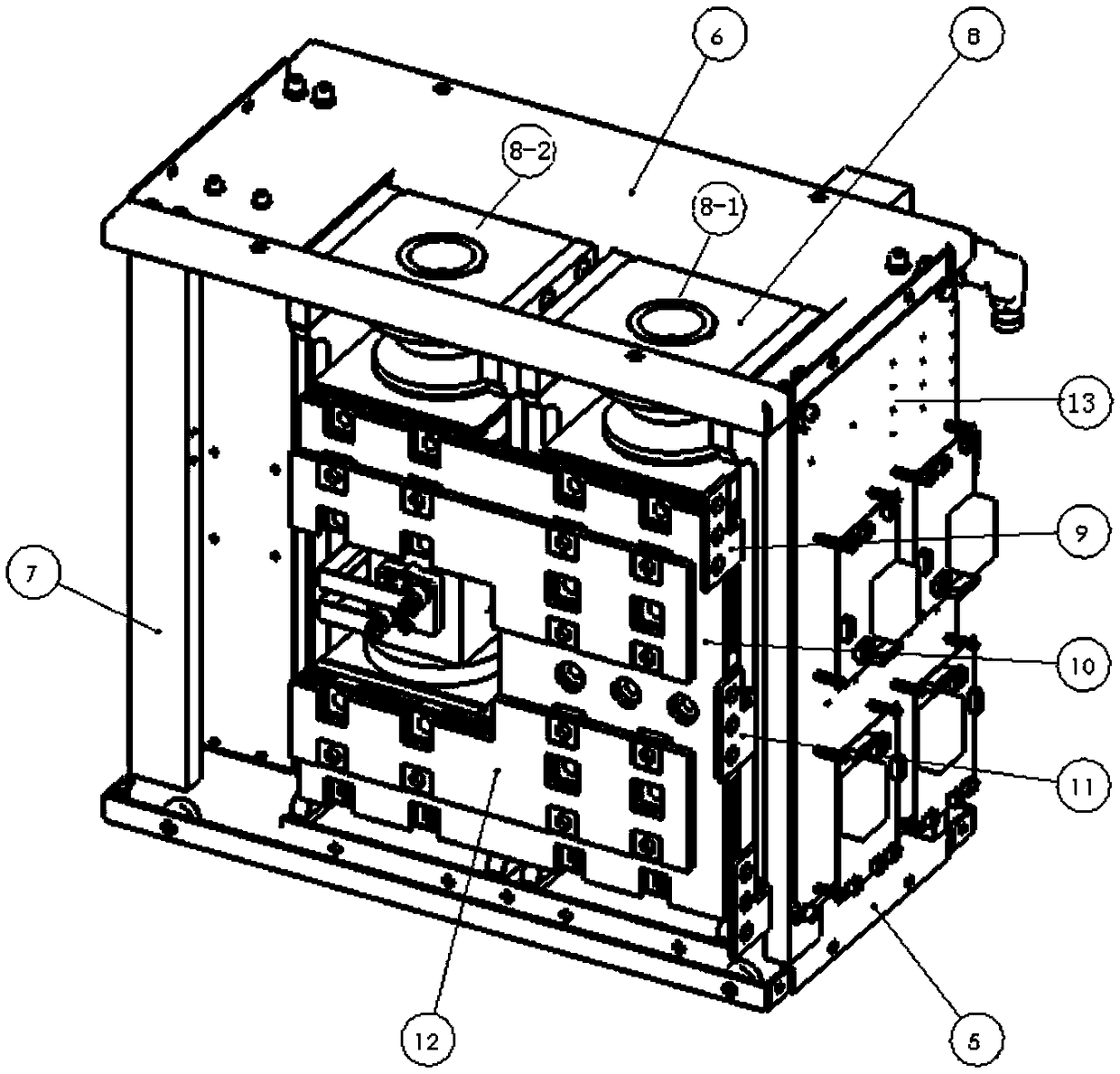

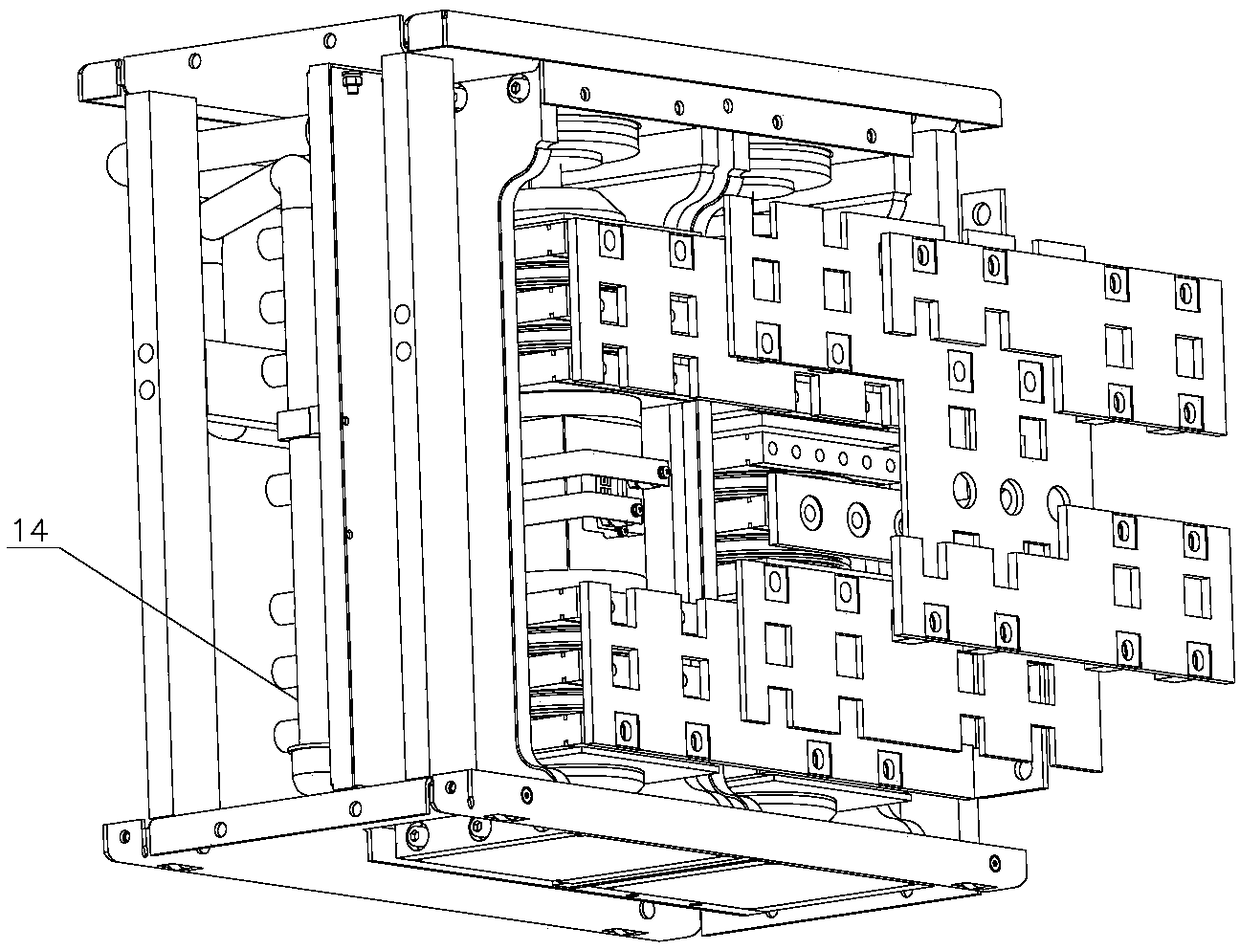

A power unit module of a frequency converter with an open frame structure

PendingCN109217641AEasy to take outEasy to assembleCooling/ventilation/heating modificationsPower conversion systemsFrequency changerComputer module

The invention provides a power unit module of a frequency converter with an open frame structure, which is a power unit module of a water-cooled heat dissipation structure, comprising a power device crimping module unit, comprising a frame composed of an upper top plate, a bottom plate and a support column and two power device crimping modules in the frame; The two power device crimping modules are two independent frame structure power device crimping modules, the top plate and the bottom plate openings of the frame are exposed on two end faces respectively, the two power device crimping modules realize the electrical connection of the power devices in the two power device crimping modules through a composite bus bar, Two independent power modules which can be extracted directly from the outside of the frame and a composite bus-bar structure which can be used for parallel connection of two independent power modules simultaneously are adopted to solve the problems of large size and highcost of large-capacity power units, great assembly difficulty, long time and difficulty for new assembling workers to get started.

Owner:RONGXIN HUIKO ELECTRIC TECH CO LTD +1

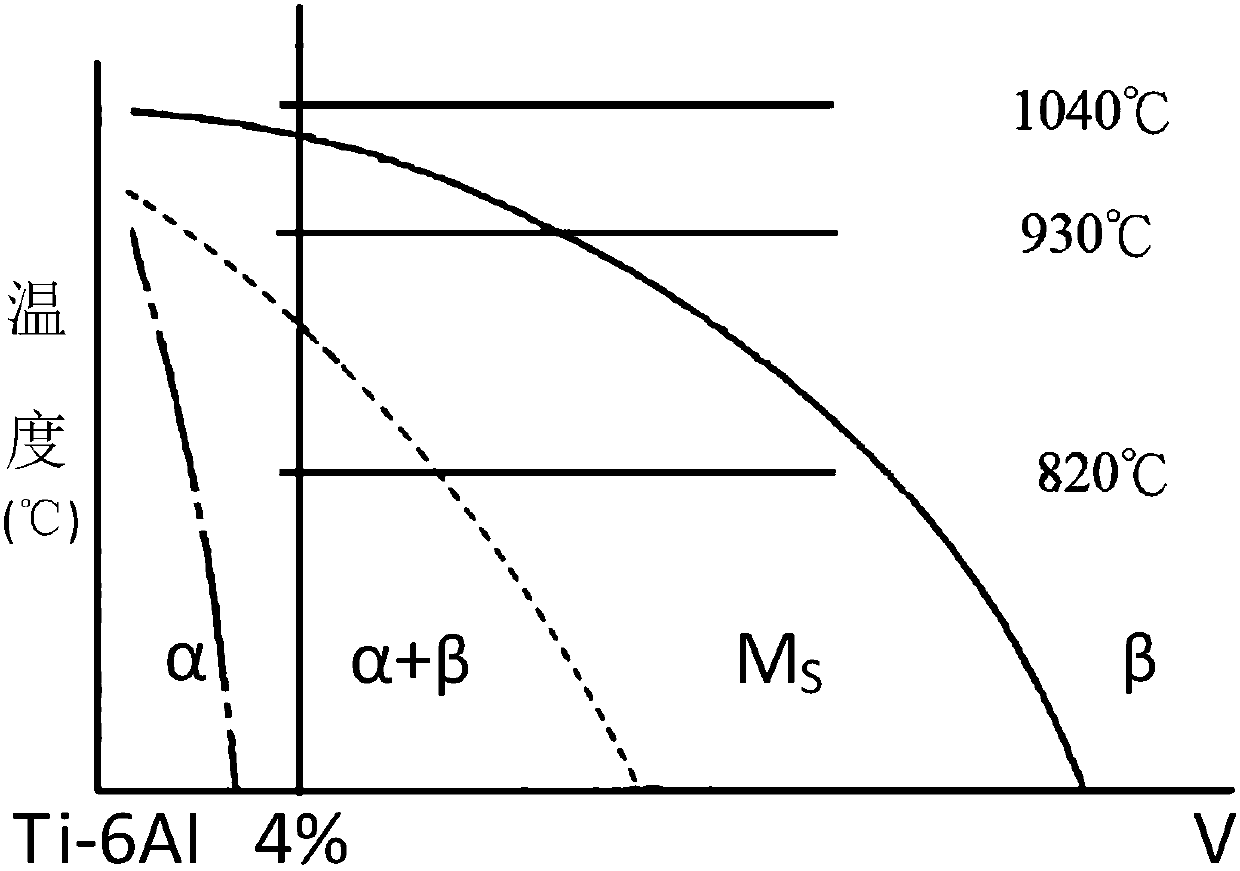

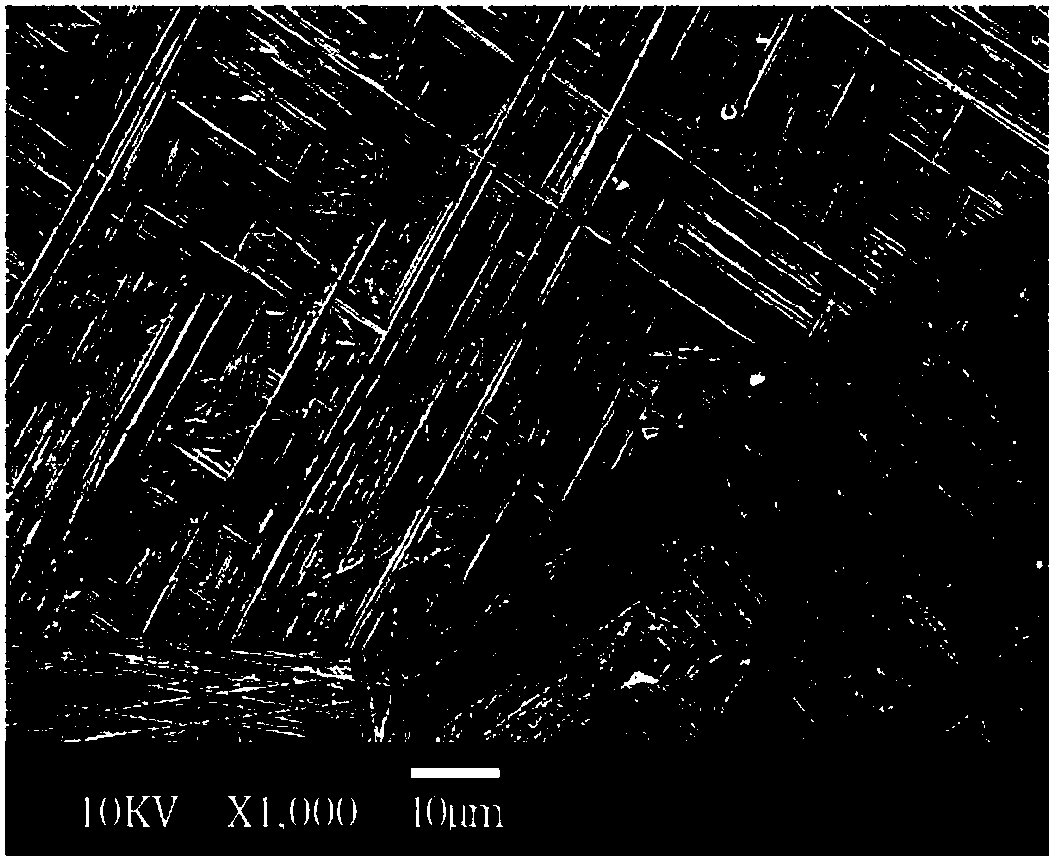

Duplex-phase golf club head titanium alloy

The present invention discloses a duplex-phase golf club head titanium alloy, which contains 6.0-7.5 wt% of aluminum, 1.5-2.5 wt% of vanadium, 1.5-2.5 wt% of chromium, 0.1-0.5 wt% of iron, 1.5-2.5 wt%of tin, 1.5-2.5 wt% of zirconium, 0.1-0.5 wt% of silicon, and other trace elements inevitable in an alloy material manufacturing process and with the ratio by using titanium as a base material. According to the present invention, after the duplex-phase golf club head titanium alloy is subjected to 780-840 DEG C plastic processing and heat treatment, the alloy structure with the alpha phase and the beta phase can be obtained; and due to the combination of the multiple alloying elements, the subgrain and high-density differential arrangement structure is generated in the alloy matrix, and the trace amount of the fine omega-phase precipitate can be formed, such that the duplex-phase golf ball bar head titanium alloy can have the tensile strength of 1300-1450 MPa, have the yield strength of 1250-1400 MPa, and the elongation of 6-12% so as to improve the design space of the golf club head structure.

Owner:O TA PRECISION IND

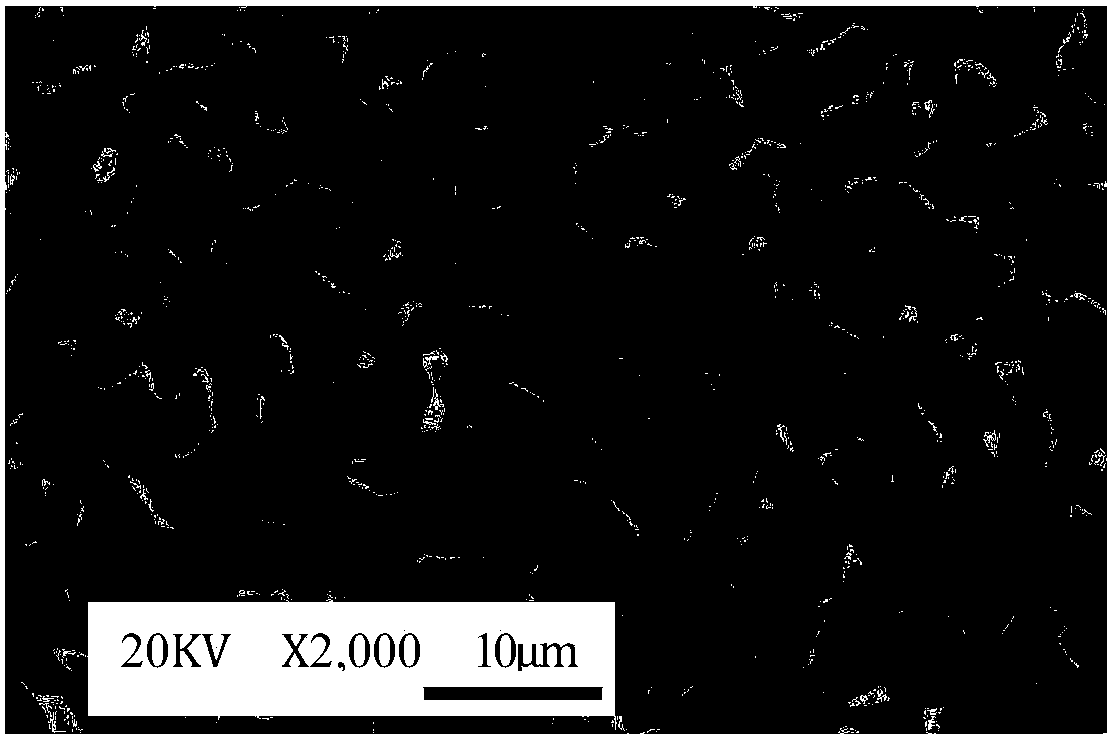

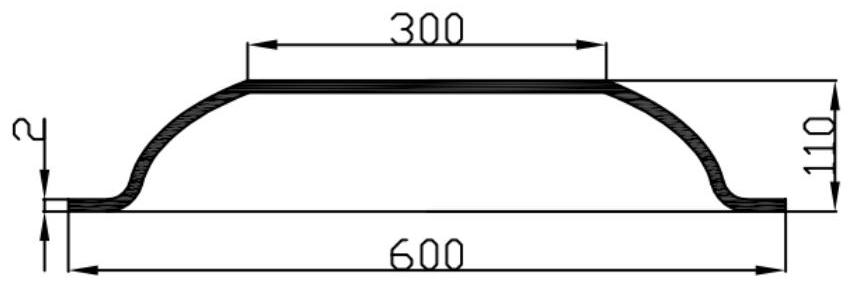

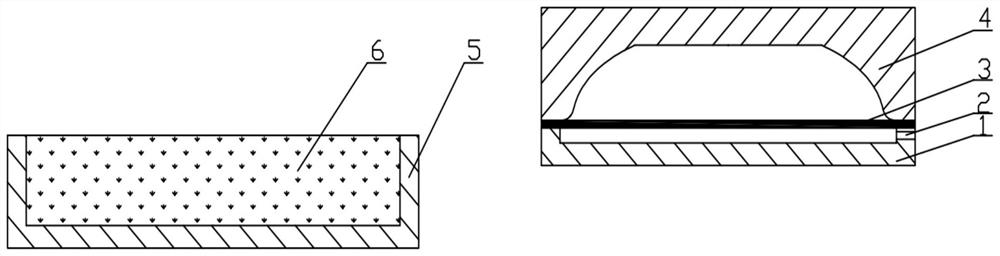

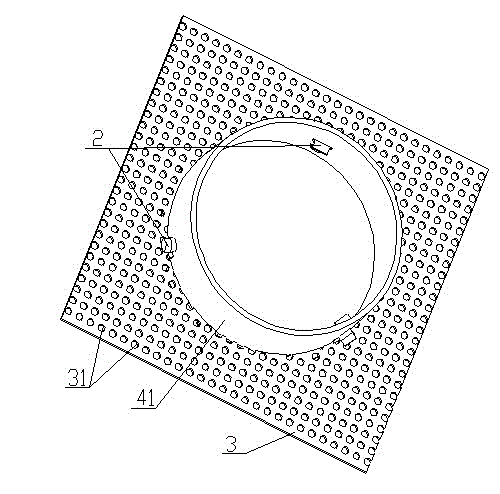

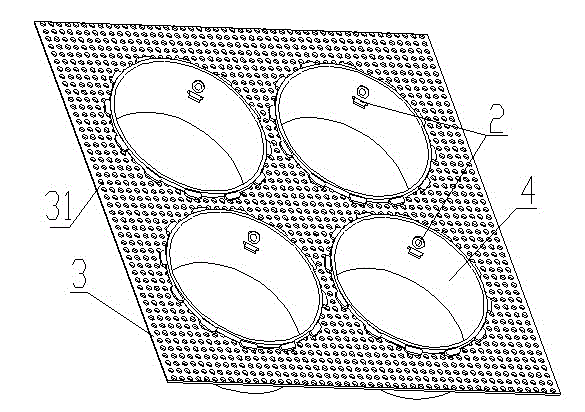

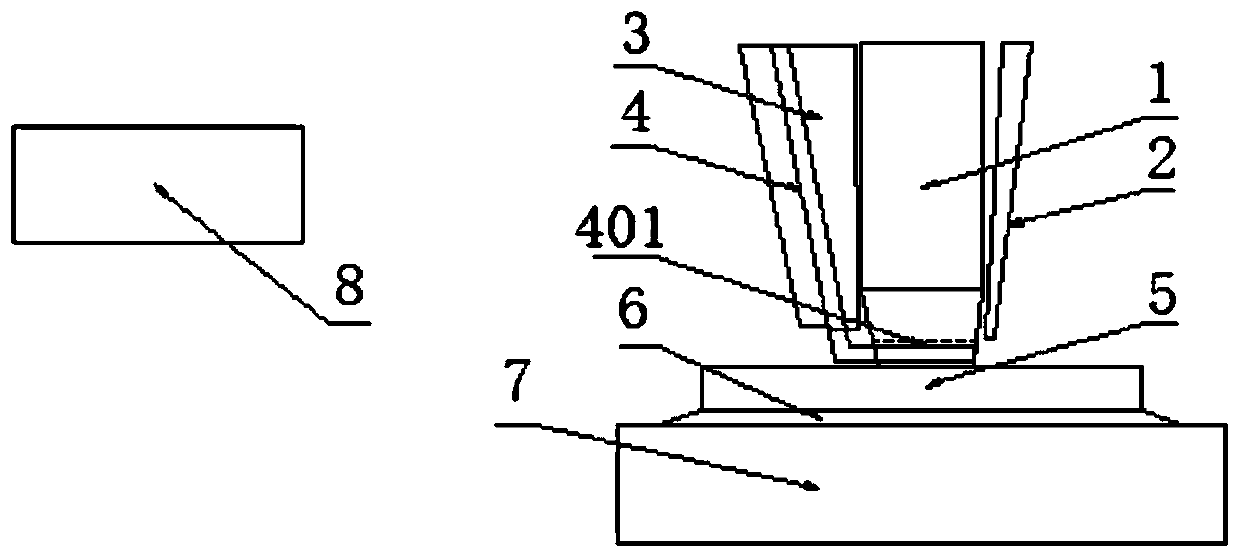

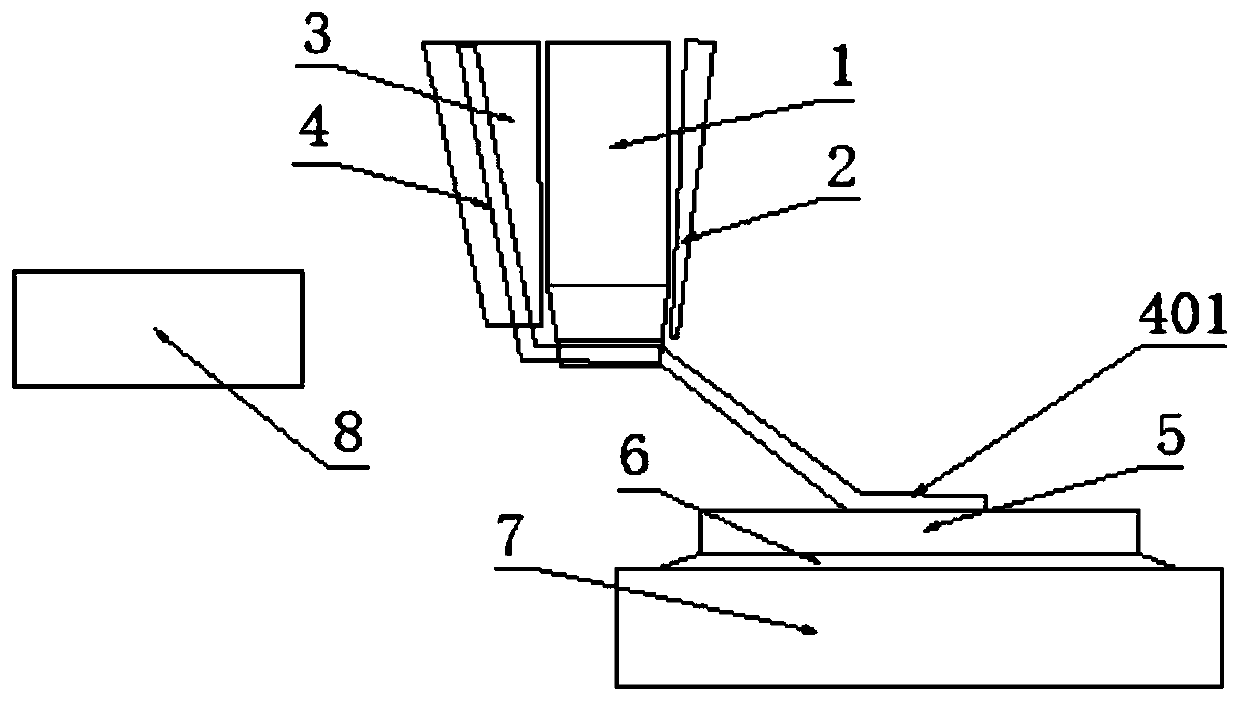

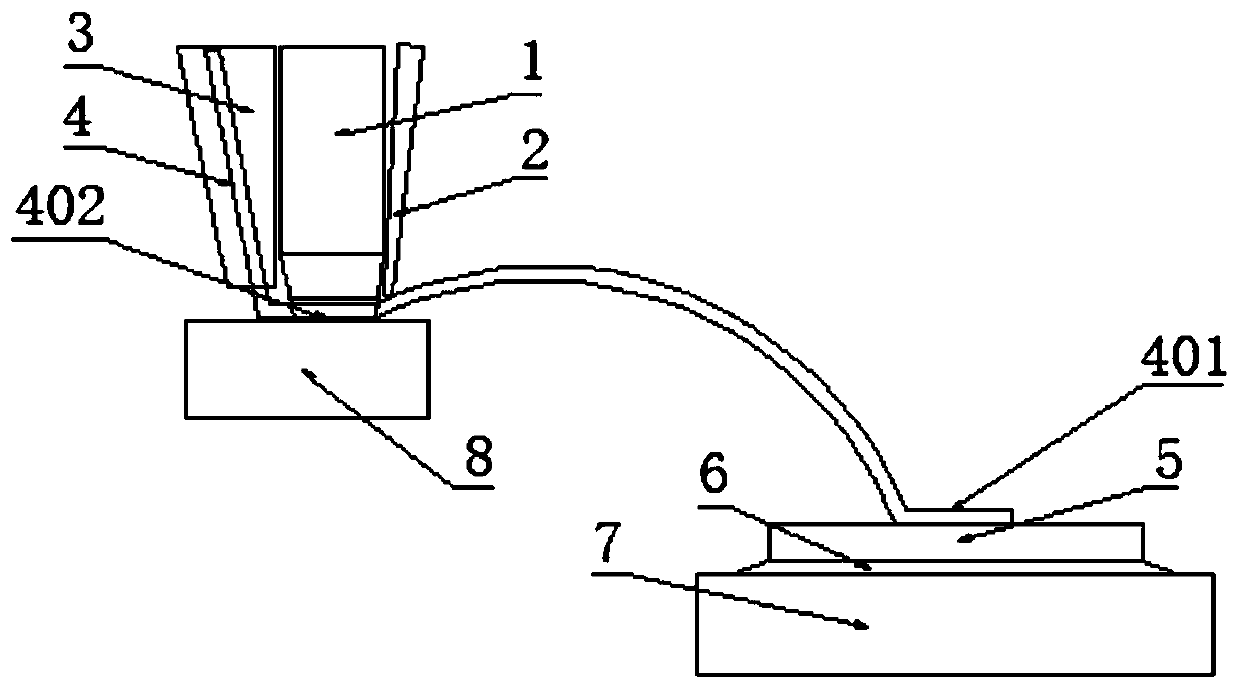

Air expansion and air quenching forming die for strengthened aluminum alloy nearly-conical thin-walled piece and method

ActiveCN111745030AImprove mechanical propertiesIncrease design spaceShaping toolsQuenching agentsMachine partsNitrogen gas

The invention discloses an air expansion and air quenching forming die for a strengthened aluminum alloy nearly-conical thin-walled workpiece and a method, and belongs to the technical field of precision metal plate machining. The problems that in the prior art, the appearance precision of a machined part is difficult to control, and the surface quality is poor are solved. The air expansion and air quenching forming die comprises an air expansion lower die (1), an air expansion upper die (4) and an air quenching die (5); and a plate material (3) is clamped between the air expansion lower die (1) and the air expansion upper die (4), the air expansion lower die (1) is provided with an air inlet (2), and the air quenching die (5) is filled with air quenching nitrogen (6). According to the dieand method, precise forming of the aluminum alloy structural part can be effectively guaranteed.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Light-emitting diode (LED) frameless multifunctional installation system

InactiveCN103604100ASimple and convenient installation structureIncrease design spacePoint-like light sourceLight fasteningsEngineeringDesign space

The invention belongs to the technical field of lamp installation structures and particularly relates to a light-emitting diode (LED) frameless multifunctional installation system. The LED frameless multifunctional installation system is characterized by mainly comprising a light source lamp body and an installing module. The light source lamp body is provided with a clamping groove, the installing module is provided with a movable clamp body matched with the clamping groove and is further provided with a mounting plate, and at least two mounting holes are distributed in the mounting plate. The light source lamp body is provided with the clamping groove, and the installing module is provided with the movable clamp body matched with the clamping groove to let the movable clamp body be clamped in the clamping groove, so that the light source lamp body is connected with the installing module. The installing module is further provided with the mounting plate, the at least two mounting holes are distributed in the mounting plate, and accordingly installing convenience and universe adaptation are improved. The lamp installation structure is simple and convenient and suitable for any lamp model and is also not subjected to limitation of the number of the light source lamp bodies, and design space for the lamp installation structure is greatly improved.

Owner:ZHONGSHAN DIKELI LIGHTING ELECTRICAL APPLIANCE

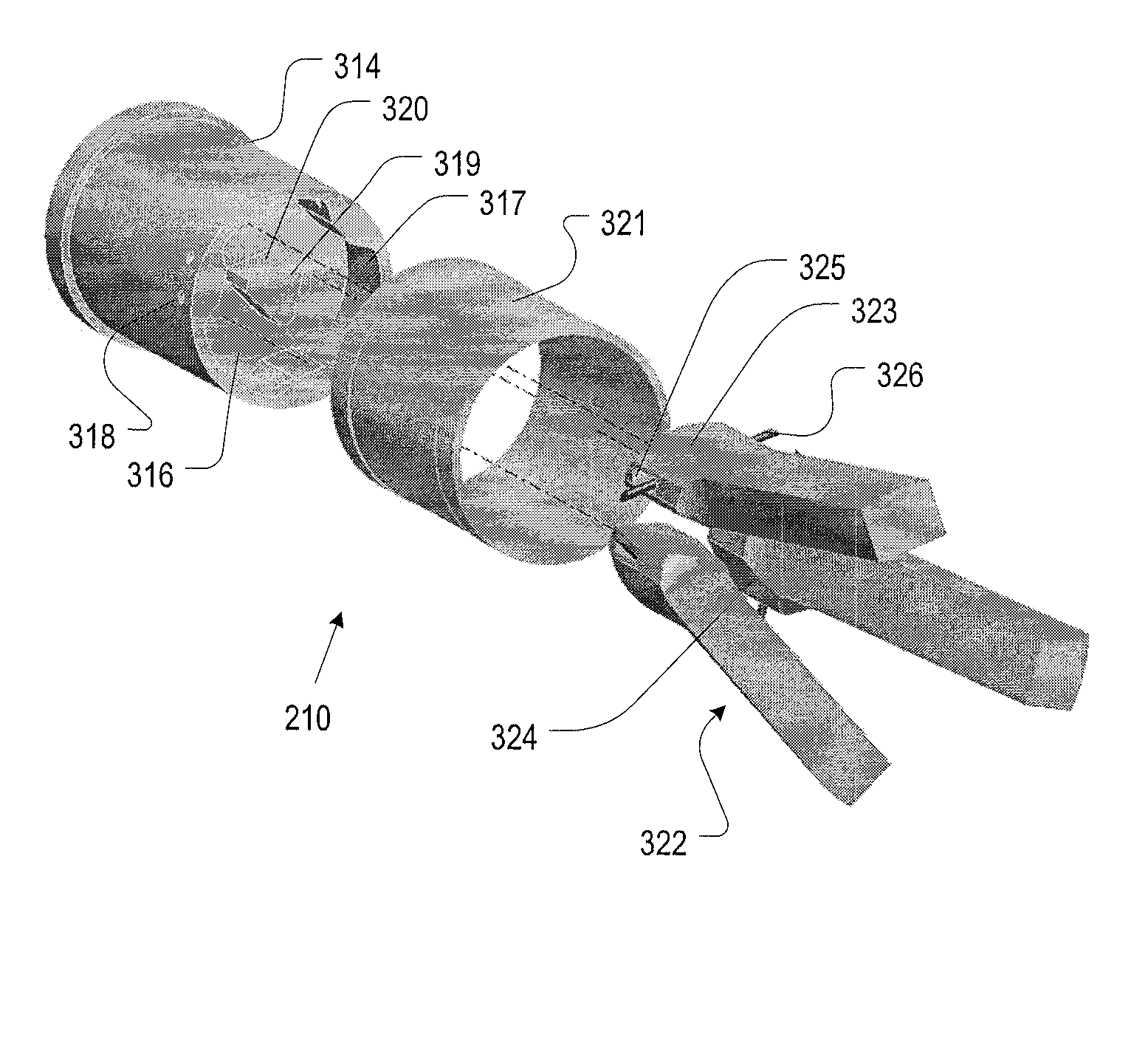

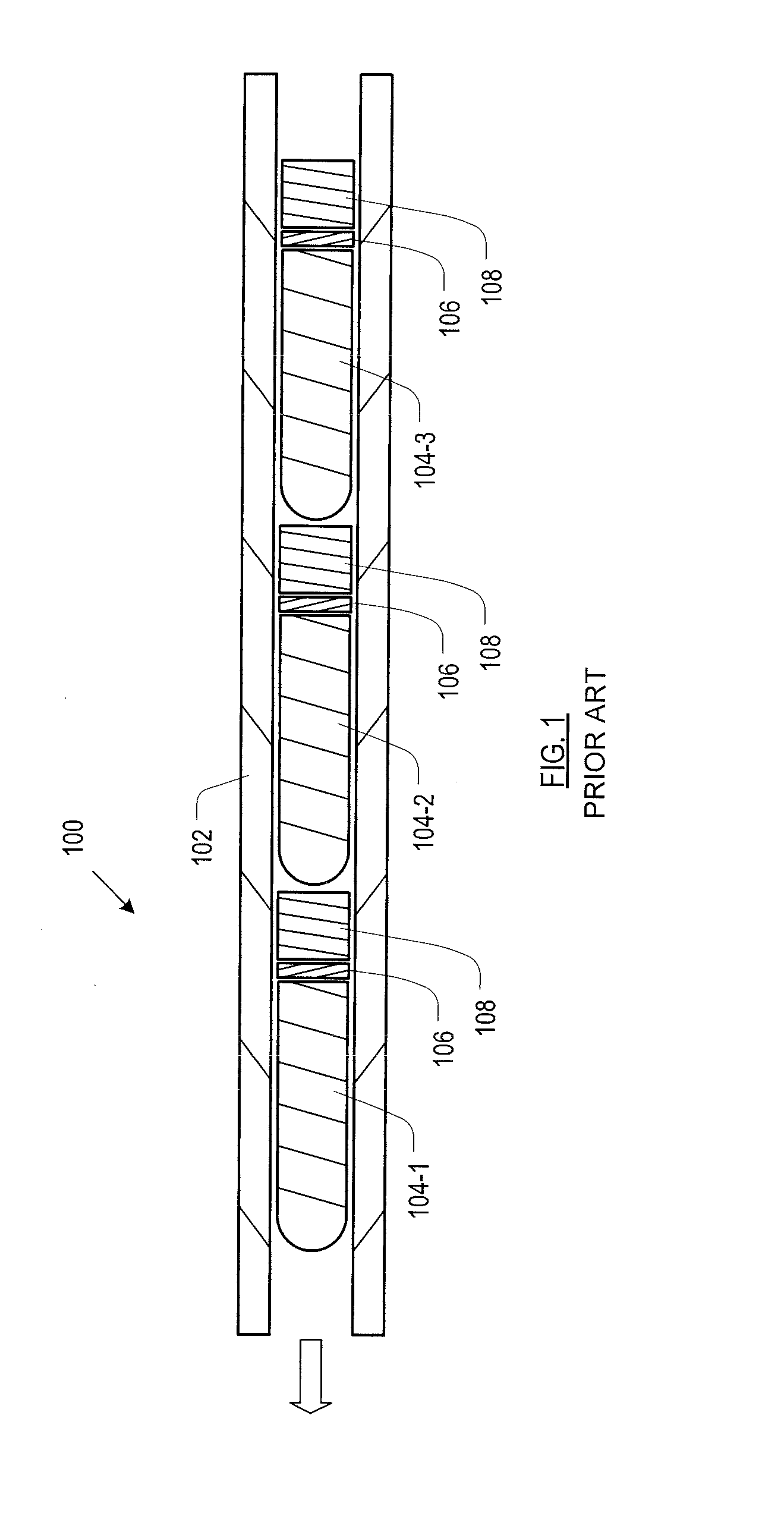

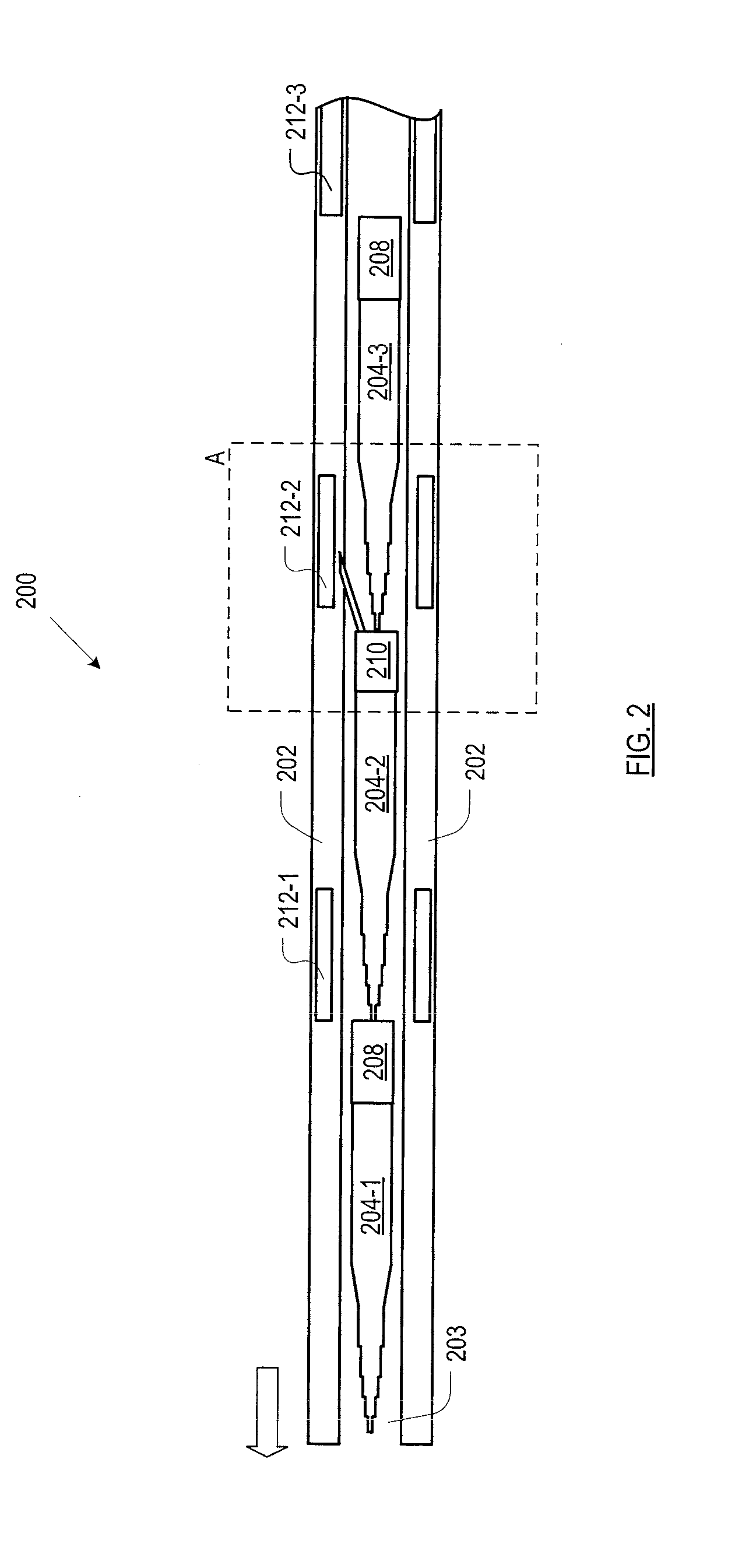

Multi-Shoot Launcher Comprising a Load-Redirecting Pusher Plate

InactiveUS20120210856A1Reduce resistanceIncrease speedAmmunition projectilesTorpedo launchersEngineeringCompression member

Stacked munitions are launched at high velocity from a launcher by redirecting, to the barrel of launcher, the static load that would otherwise be borne by the nose the projectile in position three for launch. This is accomplished via a load-redirecting pusher plate comprising a load-receiving surface and a plurality of compression members.

Owner:LOCKHEED MARTIN CORP

Efficient welding method for semiconductor packaging

InactiveCN111063622AIncrease design spaceAvoid spaceSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor packagePhysics

The invention belongs to the technical field of semiconductor packaging, and particularly relates to an efficient welding method for semiconductor packaging. The efficient welding method comprises thesteps of according to the number of welding wires of a product, selecting a multi-purpose spool, a multi-hole threading pipe, a multi-head wire conduit and a multi-welding-wire-groove chopper which match one another; carrying out multi-purpose spool fixing and welding wire conveying; welding a welding wire on the chip; forming a line arc; and carrying out frame pin welding. By means of the welding method, multiple welding wires can be welded to a single product at a time, and the wire welding operation efficiency is improved extremely efficiently. By means of the welding method, when multiplewelding wires are welded at a time, gaps and spaces reserved in a traditional welding mode can be avoided, and higher design space is brought to the design of a chip pressure area. The original chippressure area can contain the welding wires with the larger wire diameter, and the requirement for higher breakover current is met.

Owner:常州市润祥电子科技有限公司

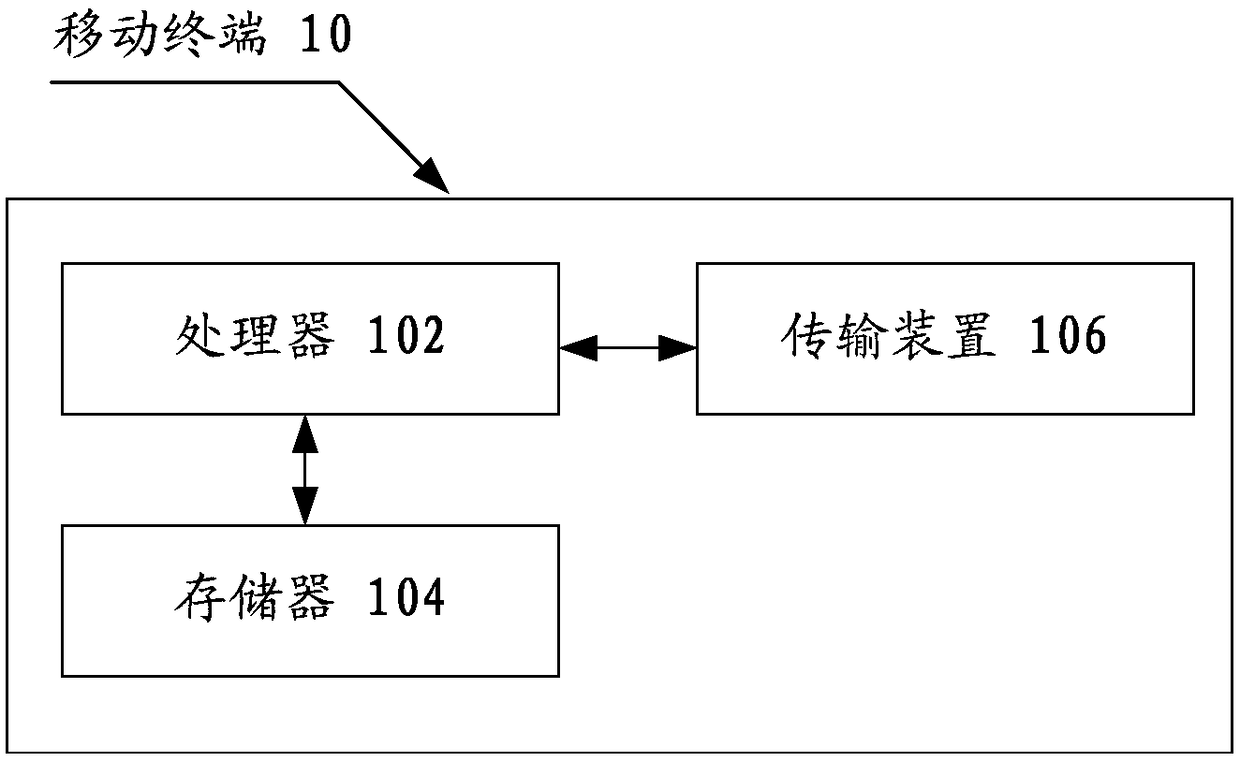

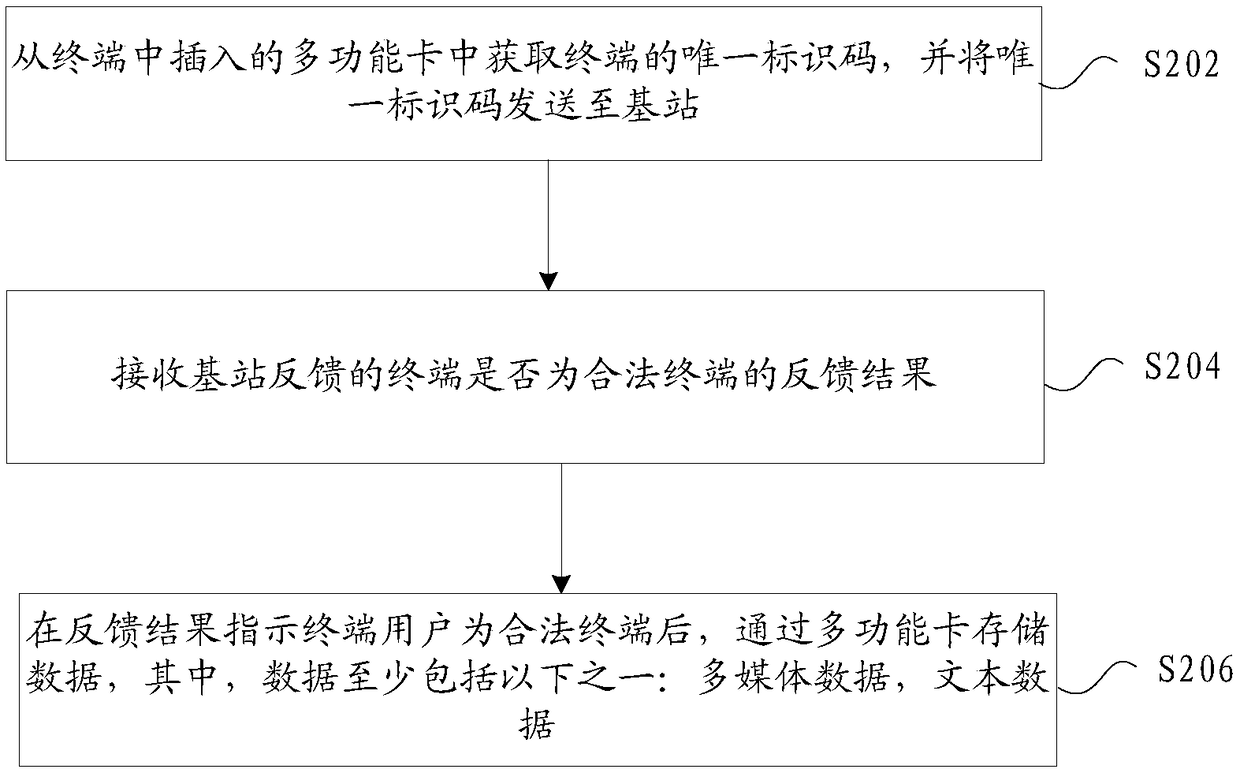

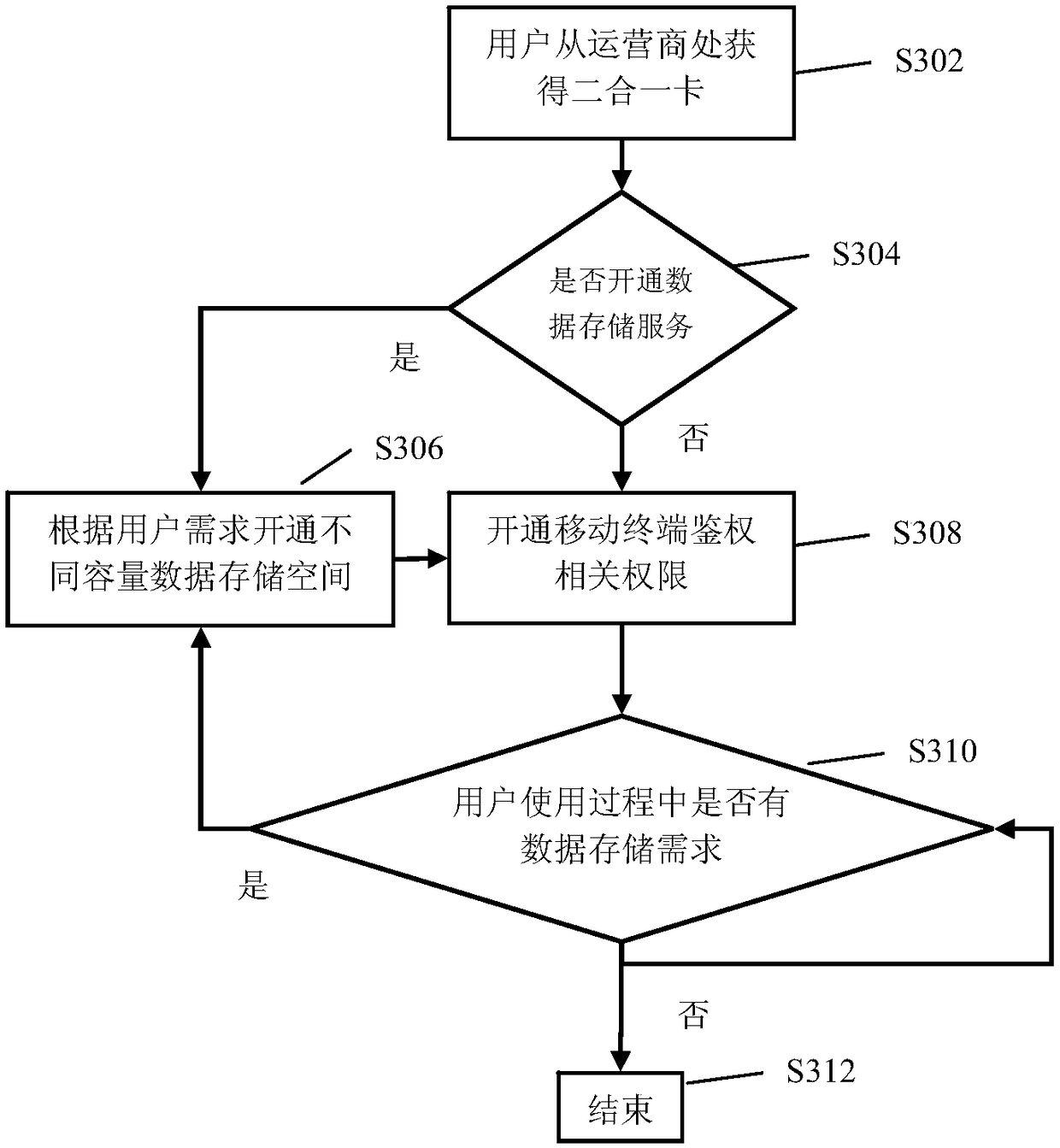

Data storage method and device, multi-function card, and storage medium

PendingCN109117081AIncrease profit pointLow costInput/output to record carriersSecurity arrangementComputer terminalBase station

The invention provides a data storage method and device, a multi-function card and a storage medium, wherein, the method comprises the following steps: obtaining a unique identification code of a terminal from a multi-function card inserted in the terminal, and sending the unique identification code to a base station; receiving a feedback result of whether the terminal fed back by the base stationis a legitimate terminal; after the feedback result indicates that the terminal is a legitimate terminal, data is stored through the multi-function card, wherein the data includes at least one of multimedia data and text data. The adoption of the technical scheme, in the related art, when the terminal simultaneously applies the SIM card and the Micro SD card, the appearance of the card slot is affected, the design requirement of the PCB version is high, and the operation of the researcher is complicated in the research and development stage, and the functions of the SIM card and the Micro SDcard can be realized by a multi-function card. The invention solves the problems that the terminal simultaneously applies the SIM card and the Micro SD card in the card slot design, and the like.

Owner:ZTE CORP

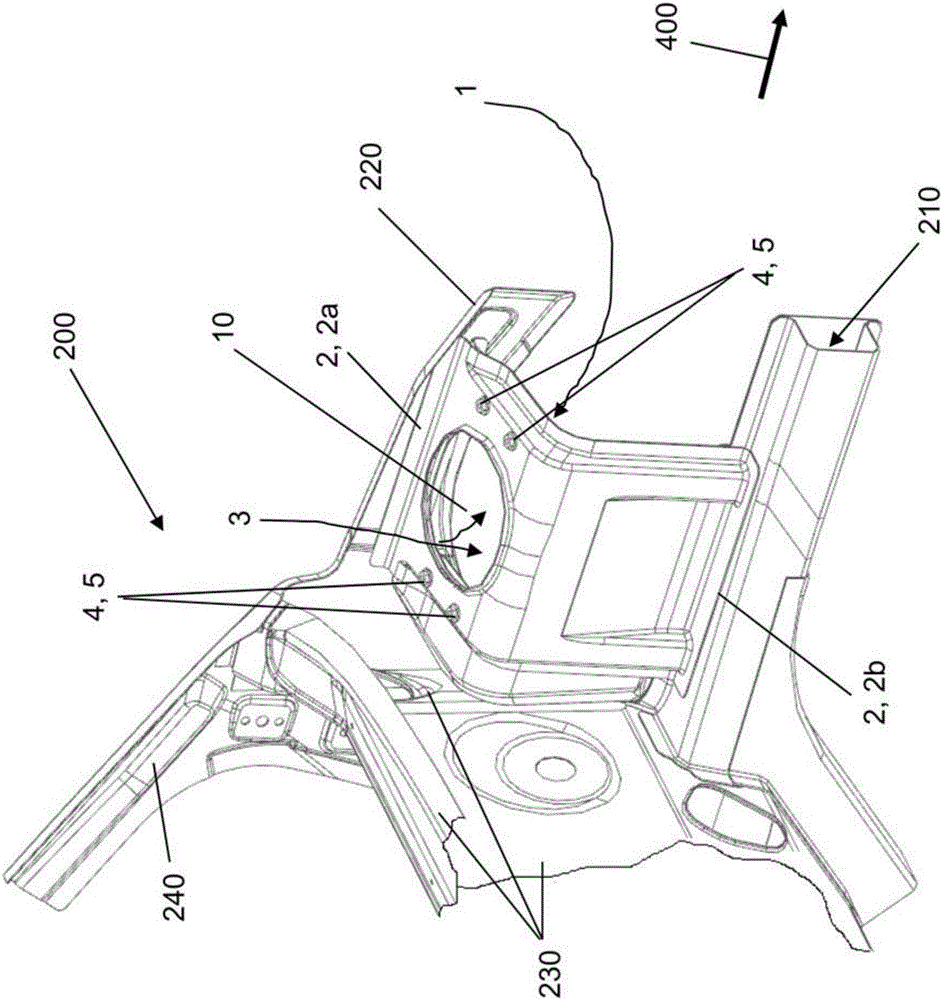

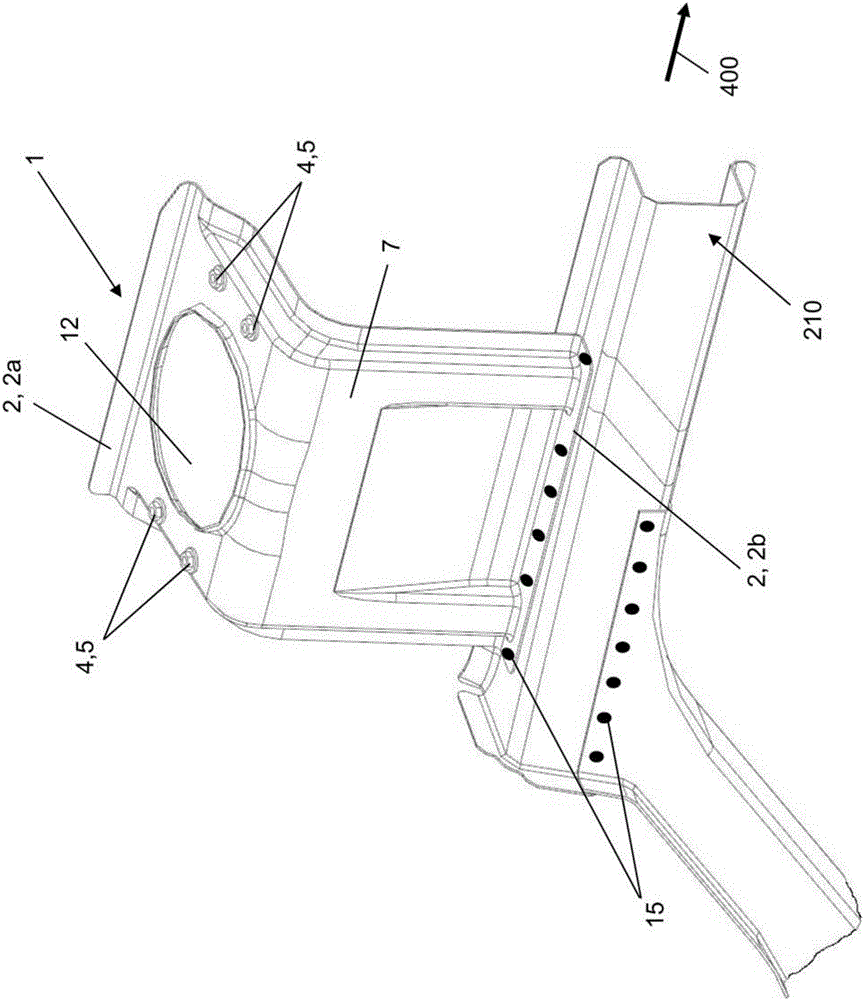

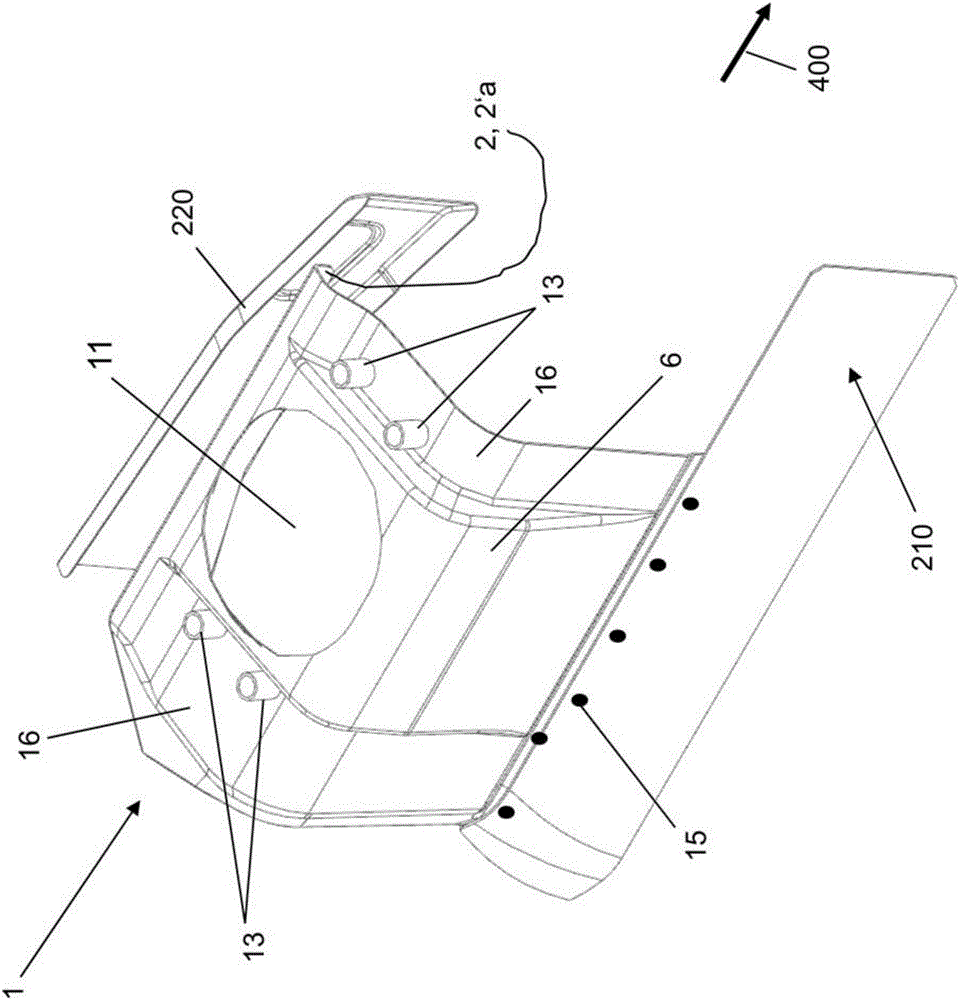

Support structure component for connecting a spring strut to a vehicle body, method for mounting a spring strut on a vehicle body and vehicle body

ActiveCN105523089AFixed and durableBottom downSuperstructure subunitsResilient suspensionsEngineeringFlange

The invention relates to a support structure component (1) for connecting a spring strut (100) to a vehicle body (200) with at least one connection section (2) for connection to a vehicle body (200) and with at least one flange section (3), which is designed for attaching a spring strut mounting (50), on which a spring strut (100) is mounted. The invention furthermore relates to a spring strut mounting (50) for attaching to the support structure component (1) with a basic body (51), on which a spring strut (100) for a motor vehicle can be mounted. In addition, the invention comprises a construction unit (300) with a spring strut mounting (50) and a spring strut (100). The invention also comprises a vehicle body (200) and a method for mounting a spring strut (100) to a vehicle body (200) provided with a support structure component (1).

Owner:GM GLOBAL TECH OPERATIONS LLC

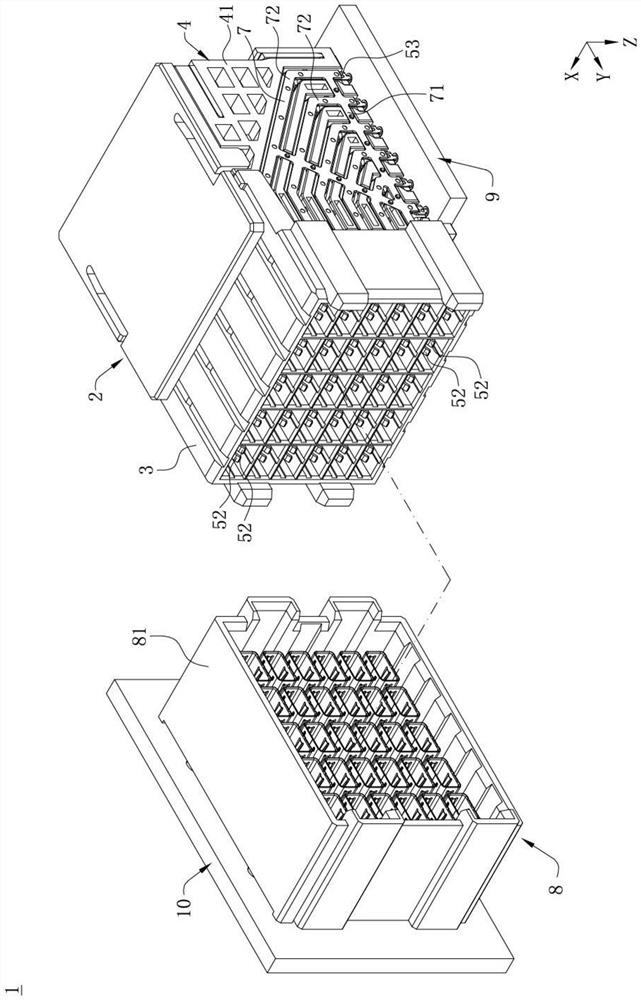

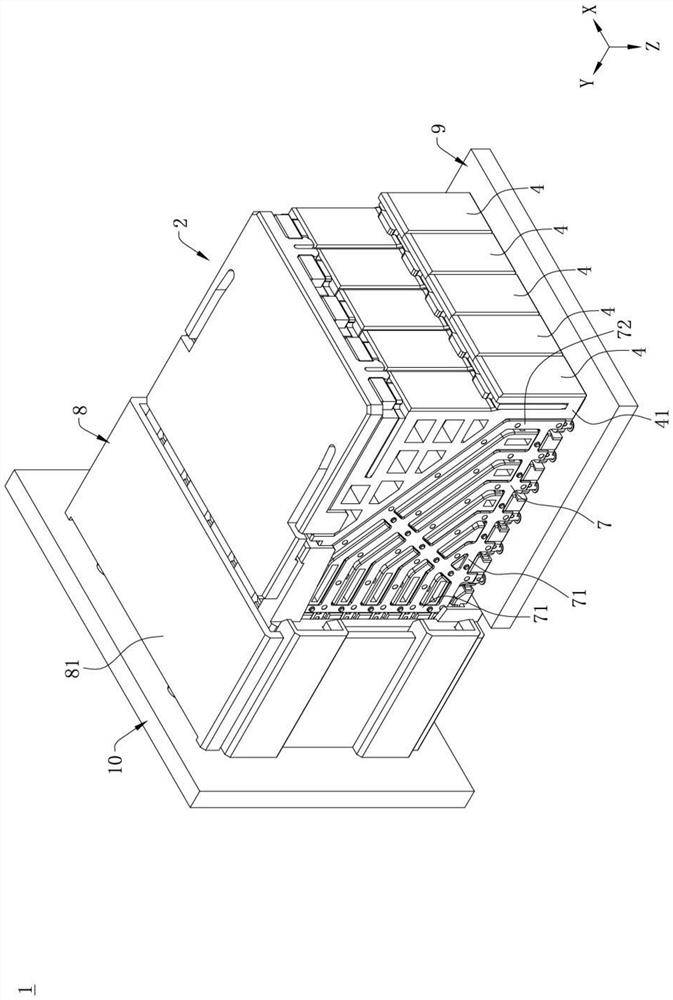

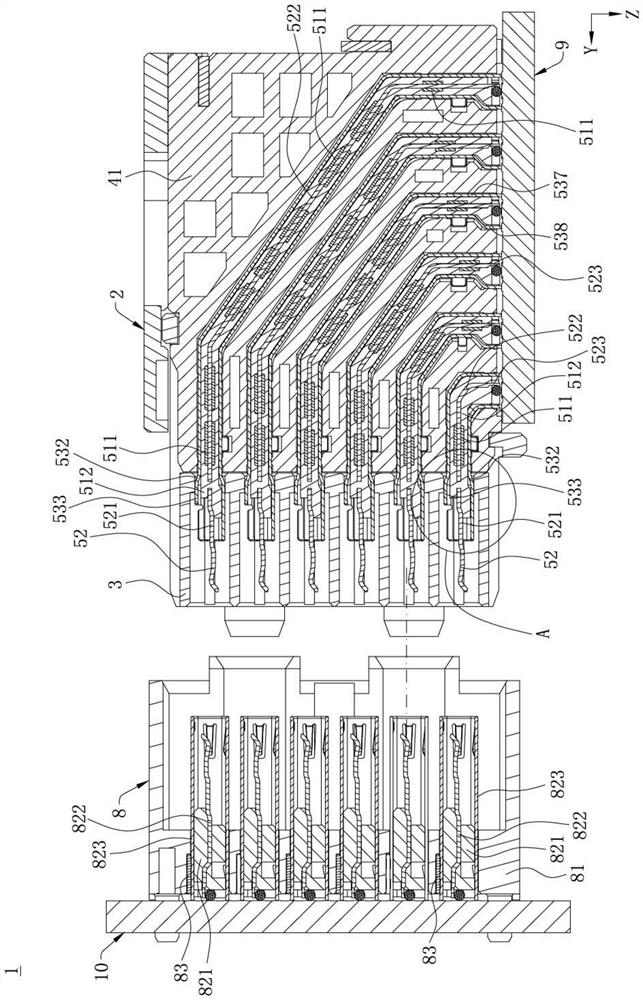

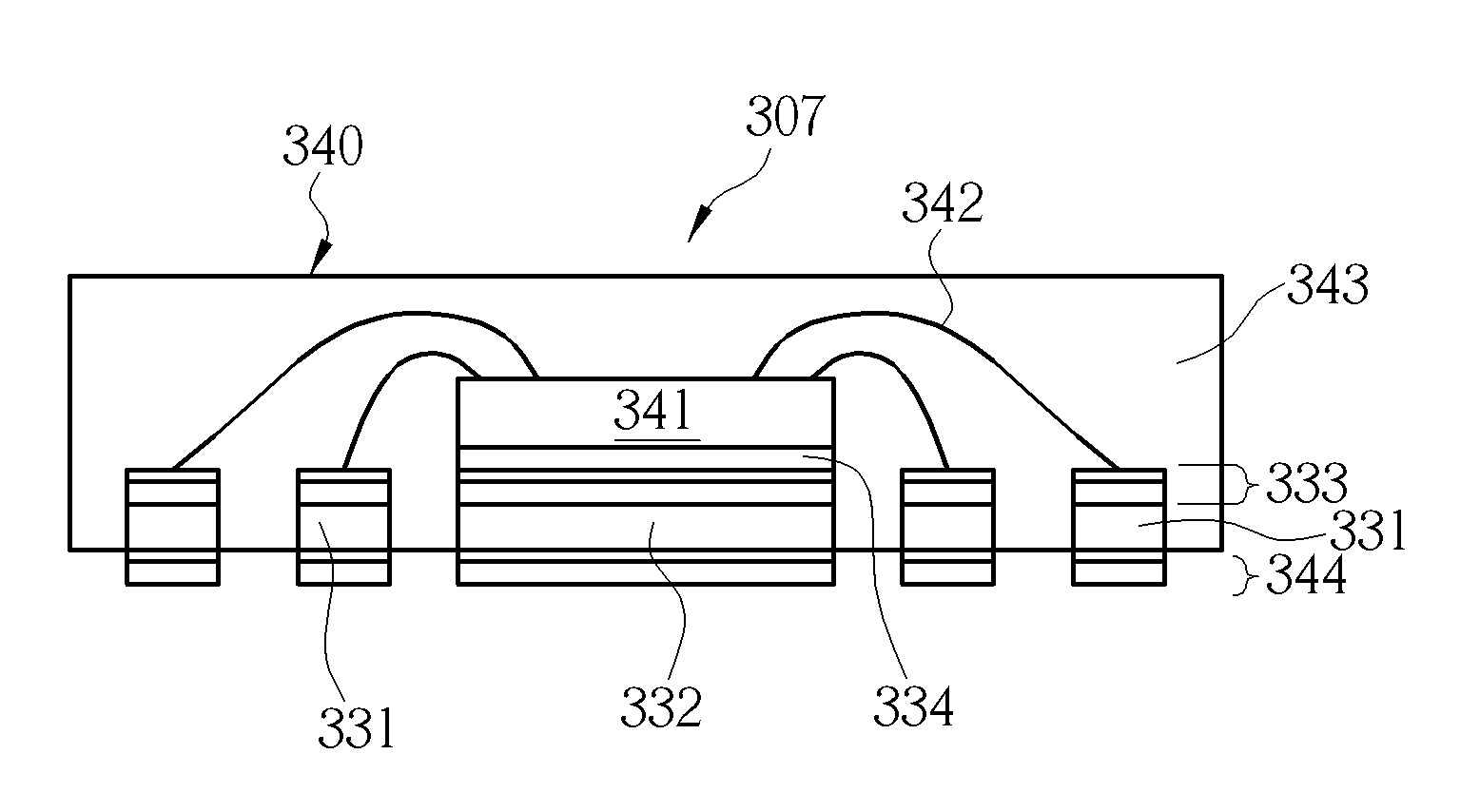

Electric connector

ActiveCN113193407AReduce signal transmission delayEasy transferSecuring/insulating coupling contact membersCoupling protective earth/shielding arrangementsElectrical connectionPhysics

The invention discloses an electric connector, which comprises at least one electric module, and is characterized in that the electric module comprises: a plurality of terminal assemblies, wherein each terminal assembly comprises two signal terminals with the same length, the two signal terminals are arranged along a first direction to form a differential pair, and the narrow sides of the two signal terminals are coupled; an insulating body which is provided with a plurality of accommodating grooves which are arranged in a second direction perpendicular to the first direction, wherein each accommodating groove is used for accommodating the corresponding terminal assembly; and at least one shielding piece which is fixed on the insulating body and is electrically isolated from the signal terminals, wherein two sides of the terminal assembly in the first direction are defined as a first side and a second side respectively, the shielding piece only shields one of the first side and the second side of each terminal assembly in the first direction, and one of the signal terminals in each differential pair is adjacent to the shielding piece in the first direction relative to the other signal terminal. The electric connector is good in high-frequency performance, interference attacks of differential pairs to outward emission can be reduced, and interference to the outside is reduced.

Owner:中山得意电子有限公司

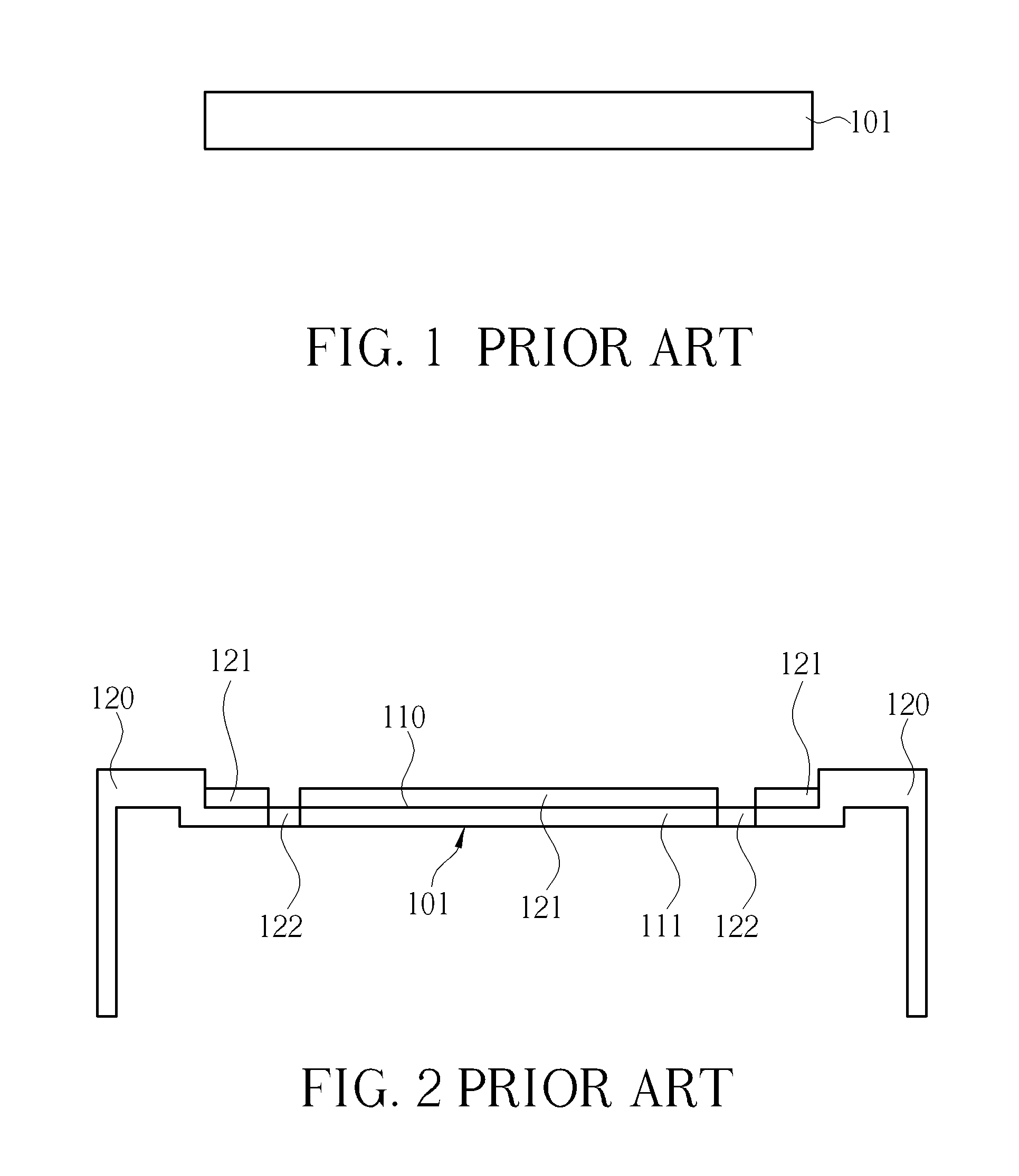

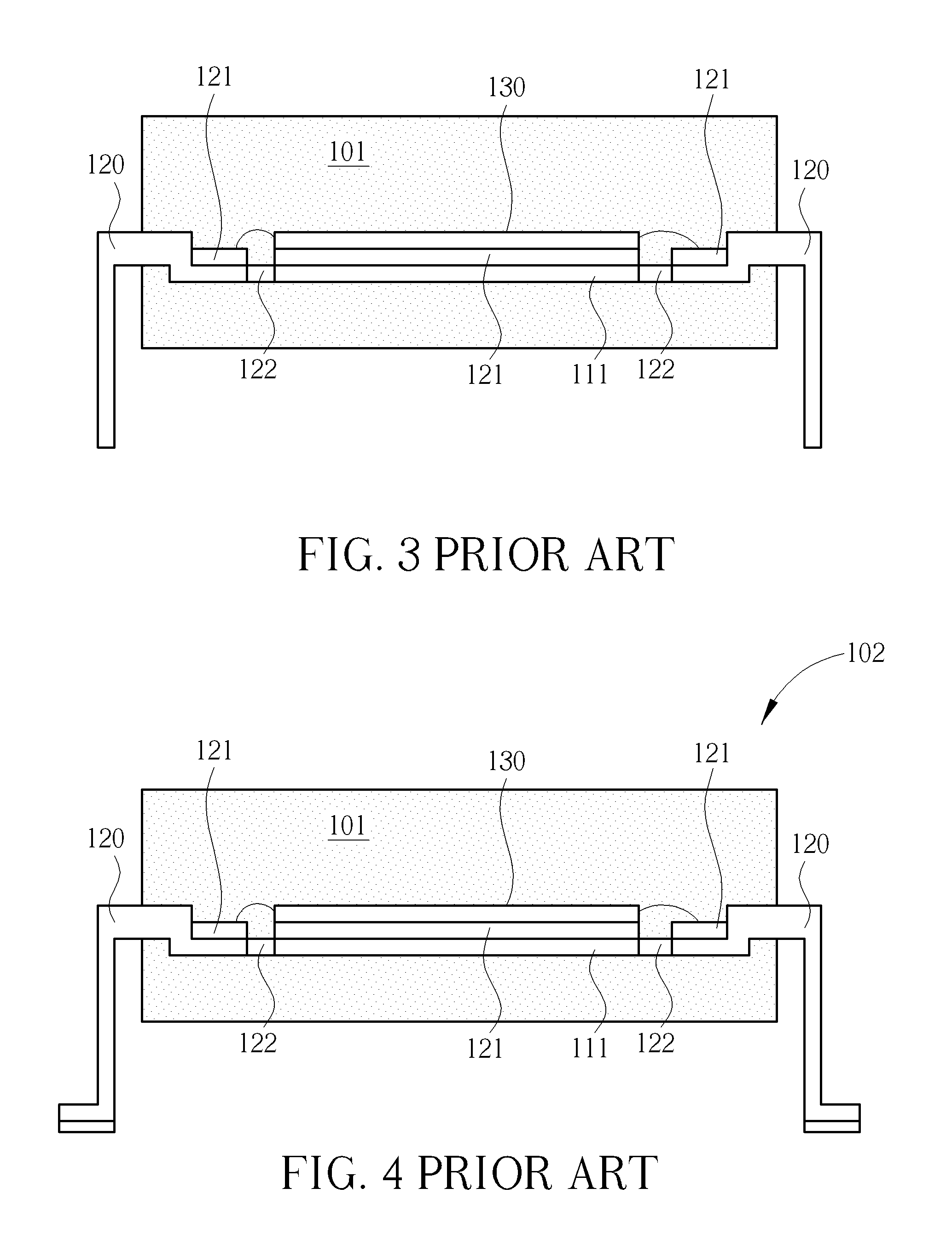

Circuit board structure, packaging structure and method for making the same

InactiveUS20110260340A1Reduce package sizeIncrease design spaceSemiconductor/solid-state device detailsSolid-state devicesBoard structureElectrical and Electronics engineering

A method for making a circuit board structure is disclosed. First, a substrate is provided. The substrate includes a carrier, a copper film and a release film disposed between them. Next, the copper film is patterned to form a connecting pattern and a die pad. Later, a passivation layer is formed to cover the connecting pattern and the die pad.

Owner:ADVANCE MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com