Air expansion and air quenching forming die for strengthened aluminum alloy nearly-conical thin-walled piece and method

A technology for forming molds and aluminum alloys, which is applied in the field of precision sheet metal processing, can solve problems such as poor surface quality and difficulty in controlling the shape accuracy of parts, and achieve the effects of guaranteeing forming accuracy, shortening production cycle, and reducing structural weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

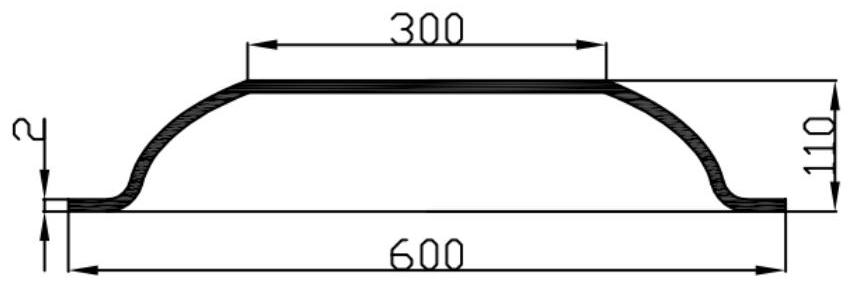

[0055] Heat-treatable strengthened aluminum alloy near-conical thin-walled parts, such as figure 1 As shown, the part material is 2A12 aluminum alloy, the shape is a pot-shaped part with a thickness of 2mm, the diameter of the large end is 600mm, the diameter of the small end is 300mm, and the height is 110mm.

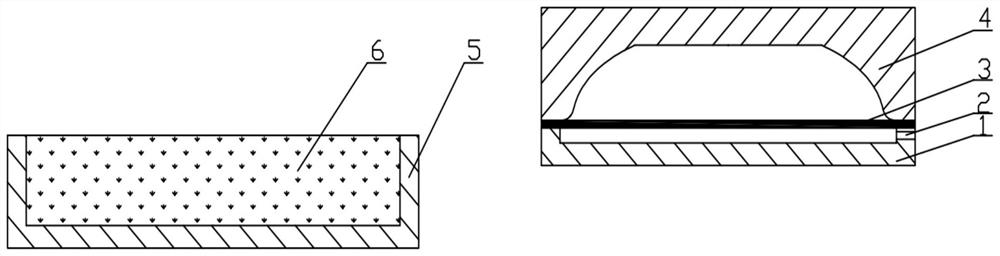

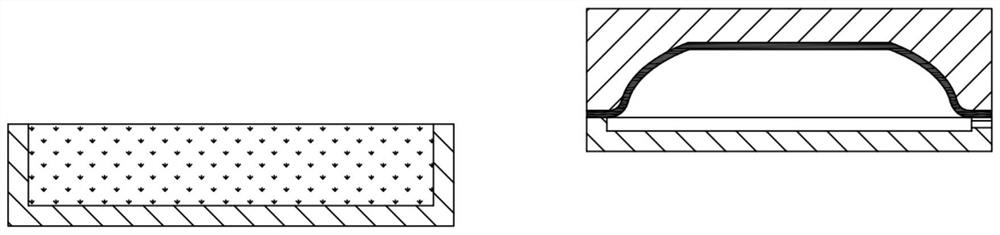

[0056] The heat-treatable and strengthened aluminum alloy near-conical thin-walled part inflated and gas-quenched forming die of this embodiment is as follows: figure 2 As shown, it includes an inflatable lower die 1, an air inlet 2, a sheet material 3, an inflatable upper die 4 and a gas quenching mold 5, the gas quenching mold 5 is equipped with gas quenching nitrogen 6, and the thickness of the sheet material 3 is t=2mm. The material of the air expansion lower mold 1, the air expansion upper mold 4, and the gas quenching mold 5 is 45# steel. Inflatable upper die 4 has an inner profile that matches the outer profile of the formed thin-walled part. The cavity of the...

Embodiment 2

[0064] Heat-treatable strengthened aluminum alloy near-conical thin-walled parts, such as figure 1 As shown, the part material is 2A12 aluminum alloy, the shape is a pot-shaped part with a thickness of 2mm, the diameter of the large end is 600mm, the diameter of the small end is 300mm, and the height is 110mm.

[0065] The heat-treatable and strengthened aluminum alloy nearly conical thin-walled thin-walled parts inflated and gas-quenched forming method of this embodiment are carried out according to the following process steps:

[0066] Step 1: Clip the sheet material 3 between the lower inflatable die 1 and the upper inflatable die 4, and the material of the sheet material 3 is 2A12 aluminum alloy;

[0067] Step 2, heating the lower inflatable mold 4, the upper inflatable mold 1 and the sheet material 3 together to the forming temperature, and the forming temperature is 505°C;

[0068] Step 3, feed gas into the lower mold 1 through the air inlet 2 of the lower mold, the gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com