Anchor system for fixing steel strand in pre-stressed structure

A prestressed structure and steel strand technology, applied in the field of anchoring systems, can solve the problems of difficult configuration of beam-column main reinforcement and node shear stirrups, volume, unit area and self-weight, and difficulty in setting, so as to improve the design. Space and constructability, improving restraint effect, compressing floor space and space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

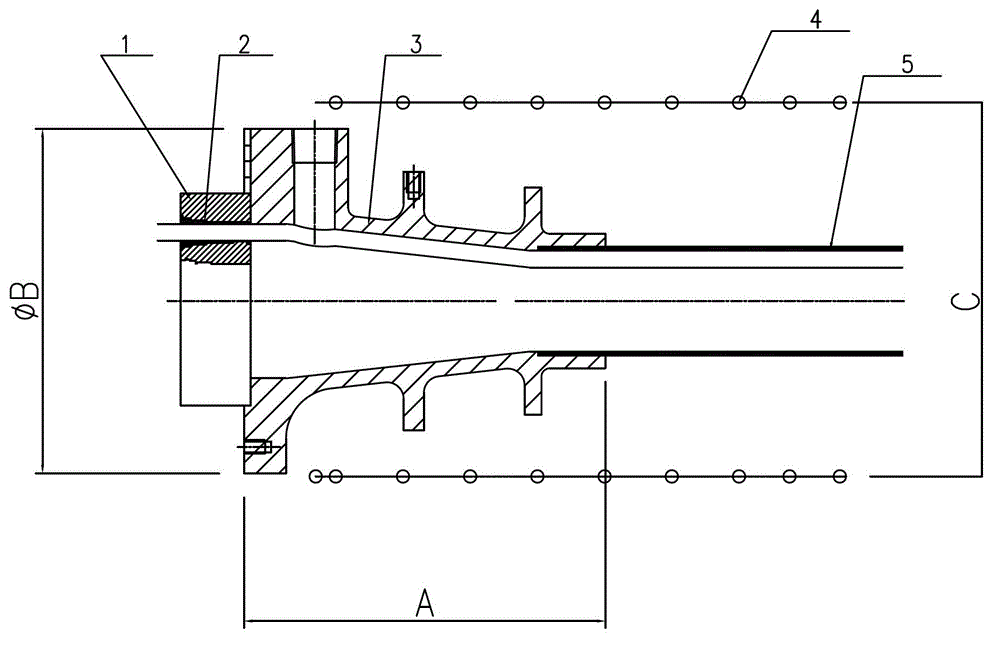

[0017] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, an anchorage system for fixing steel strands in a prestressed structure includes an anchor plate 1, an anchor backing plate 3, an anchoring spiral rib 4 and a clip 2; the anchor plate 1 has 12 Circular anchor plate 1 with three oblique holes, installed on the outermost side of the tension side of the steel strand; there are 12 sets of clips 2, which are respectively matched with 12 oblique holes, and each set of clips 2 consists of three clips. Use a hard rubber ring to form a set; the anchor plate 1 is installed directly below the anchor plate 3, and the circular hole in the middle of the anchor plate 3 is nested inside the bellows 5 reserved in the concrete member. The lower spiral rib 4 is installed on the outer periphery of the anchor backing plate 3; the main body of the anchor backing plate 3 is in the form of a tapered cylinder from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com