Self-feedback drive control system of double shape memory alloy wires and testing platform of drive control system

A technology of memory alloy wire and drive control, which is applied in the direction of electric controllers, controllers with specific characteristics, medical science, etc., can solve the problems of insufficient surgical operation space, occupying a large external space, and increased difficulty of surgery, and achieve improved design The effect of space, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

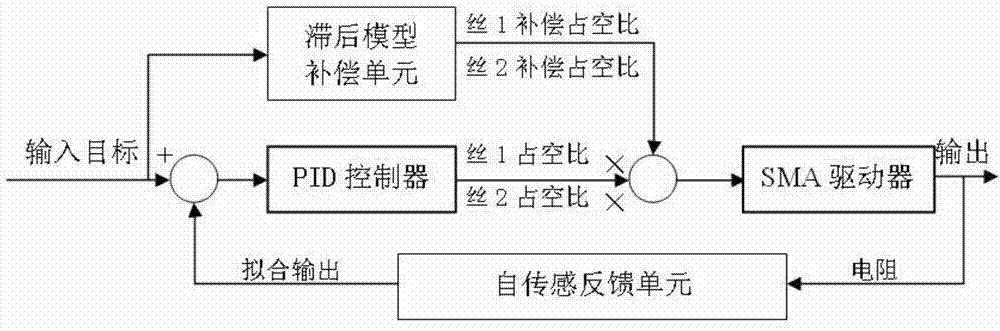

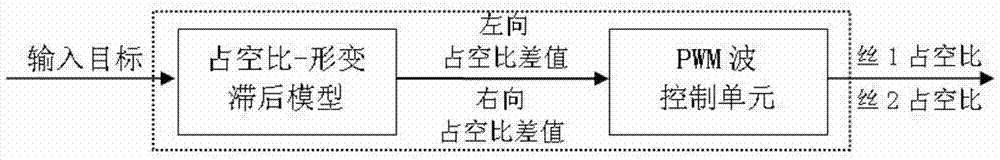

Method used

Image

Examples

specific Embodiment

[0038] The end effector used to couple and drive the endoscopic surgical robot, including the double SMA wire drive control test platform for establishing the control model and verifying the control effect and accuracy of the drive:

[0039] like image 3 As shown, the circuit control module outputs different PWM wave duty ratios to the first SMA driving wire and the second SMA driving wire at the same time, and the SMA wire drives the slider to move along the guide rail. The LVDT displacement sensor measures the travel distance of the slider in real time, that is, the actual strain of the SMA driving wire. The first S-type force sensor and the second S-type force sensor test in real time the stress generated by the contraction or stretching of the two SMA driving wires during the movement of the slider.

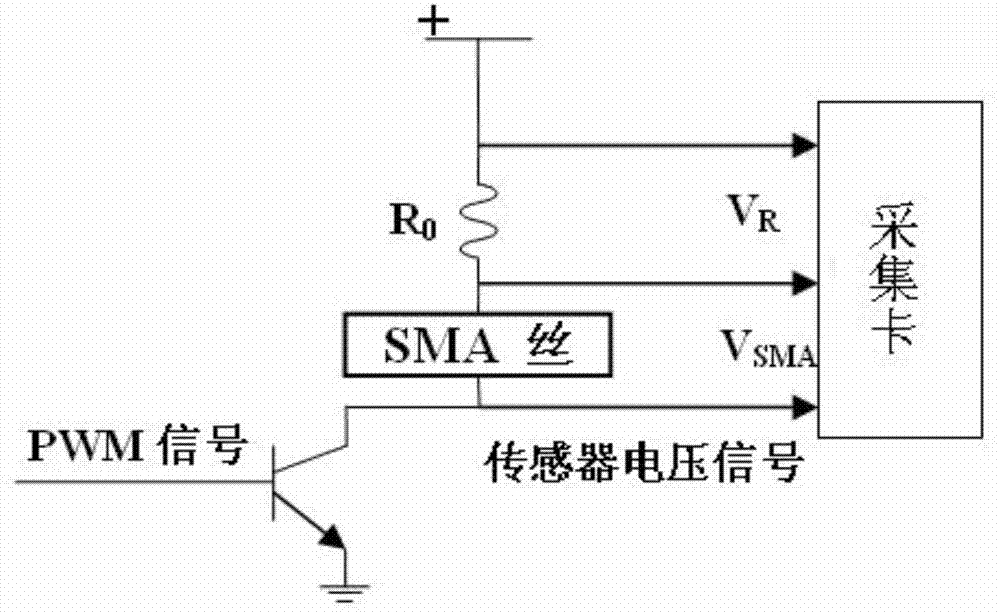

[0040] like figure 2 As shown in the figure, the standard resistor and SMA wire are connected in series with the drive circuit, and the SMA wire resistance R is obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com