Intelligent luminous wood floor

A wooden floor, intelligent technology, applied in the field of floor decoration, can solve the problems of reducing the service life of the floor, high calorific value and energy consumption, destroying lamp beads, etc., to achieve the effect of improving the service life, improving the design space, and increasing the decorative performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

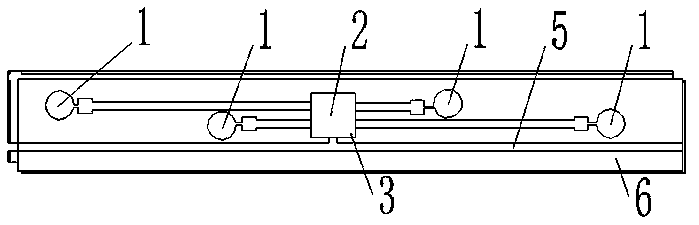

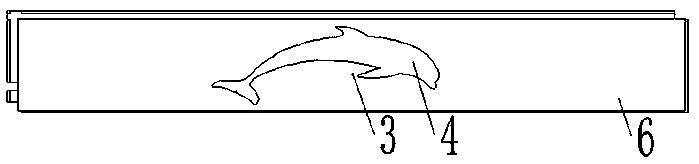

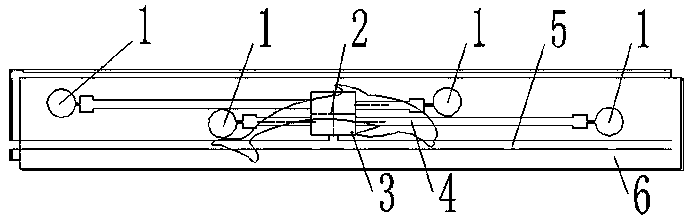

[0025] An intelligent luminous wooden floor, comprising a wooden floor body 6, an upper groove, and a lower groove. The upper groove is inlaid with a thin and narrow luminous pattern element 5, and the luminous pattern element 5 is waterproofed and sealed with epoxy resin and then coated. Covered with paint, the lower groove is inlaid with a vibration sensor and a control circuit board, the upper groove and the lower groove are connected through a drill hole 3, and the control circuit board in the lower groove is connected to the external sensor for inducing sunlight intensity. The illuminance meter is electrically connected to a 5~24V power supply. The lower groove is composed of a quadrilateral groove 2 in the middle and a circular groove 1 around it. A circuit board is arranged in the quadrilateral groove 2, and a vibration sensor is installed in the circular groove 1. For the sensor, a wire groove 4 is arranged between the circular groove 1 and the quadrangular groove 2 and...

Embodiment 2

[0028] An intelligent luminous wooden floor, comprising a wooden floor body 6, an upper groove, and a lower groove. The upper groove is inlaid with a thin and narrow luminous pattern element 5, and the luminous pattern element 5 is waterproofed and sealed with epoxy resin and then coated. Covered with paint, the lower groove is inlaid with a pressure sensor and a control circuit board, the upper groove and the lower groove are connected through a drill hole 3, and the control circuit board in the lower groove is connected to the external sensor for sensing the intensity of sunlight. The illuminance meter is electrically connected to a 5~24V power supply. The lower groove is composed of a quadrilateral groove 2 in the middle and a circular groove 1 around it. A circuit board is arranged in the quadrilateral groove 2, and a pressure gauge is respectively set in the circular groove 1. For the sensor, a wire groove 4 is arranged between the circular groove 1 and the quadrangular gr...

Embodiment 3

[0031] An intelligent luminous wooden floor, comprising a wooden floor body 6, an upper groove, and a lower groove. The upper groove is inlaid with a thin and narrow luminous pattern element 5, and the luminous pattern element 5 is waterproofed and sealed with epoxy resin and then coated. Covered with paint, the lower groove is inlaid with a microwave sensor and a control circuit board, the upper groove and the lower groove are communicated through a drill hole 3, and the control circuit board in the lower groove is connected to the external sensor for sensing the intensity of sunlight. The illuminance meter is electrically connected to a 5~24V power supply. The lower groove is composed of a quadrilateral groove 2 in the middle and a circular groove 1 around it. A circuit board is arranged in the quadrilateral groove 2, and a microwave oven is respectively arranged in the circular groove 1. For the sensor, a wire groove 4 is arranged between the circular groove 1 and the quadra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com