Combined adjustable elastic sealing disc high temperature and high pressure safety valve

An elastic sealing, high temperature and high pressure technology, used in safety valves, lift valves, balance valves, etc., can solve the problems of uneven matching between the sealing surface of the disc and the sealing surface of the valve seat, sealing failure, and lowering of the set pressure. Fear, motor performance safety, the effect of eliminating positional changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

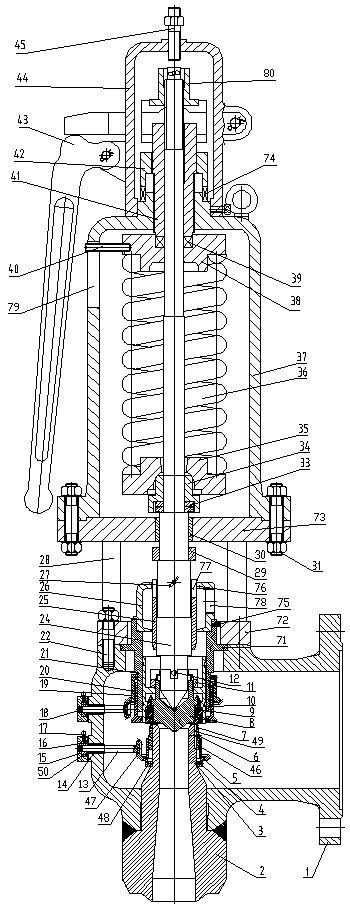

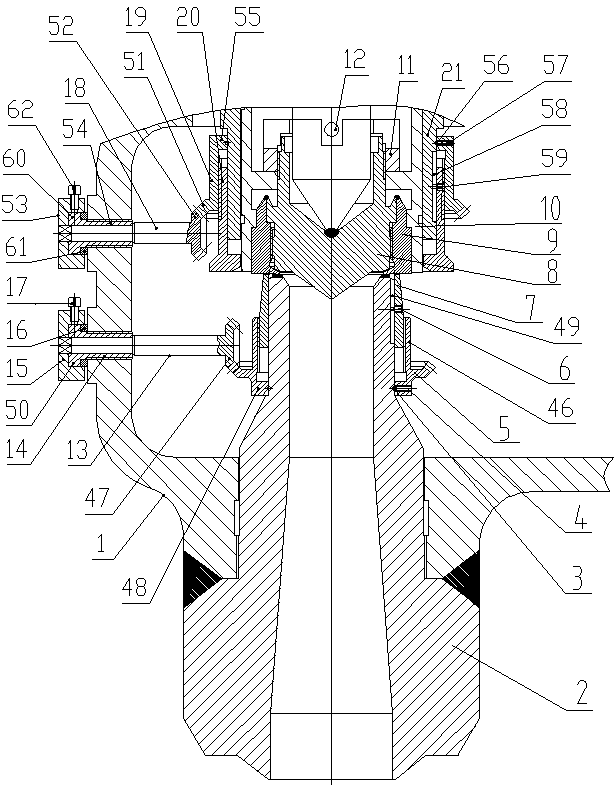

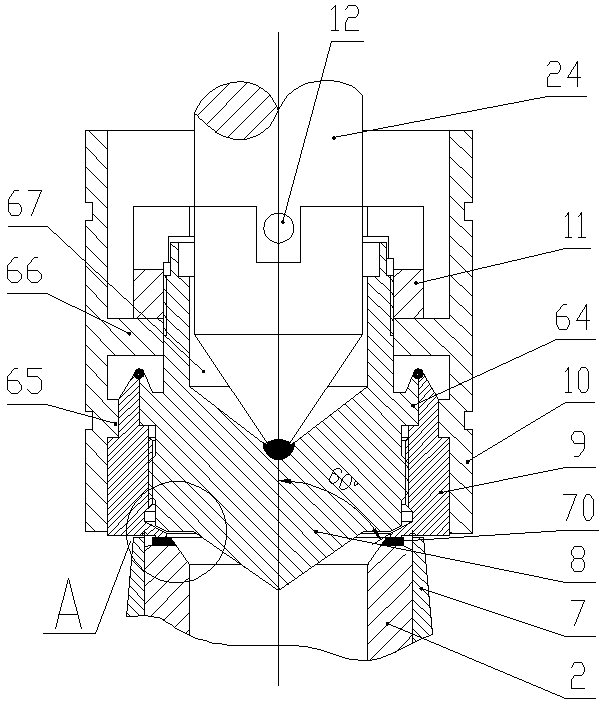

[0051] Such as Figure 1-Figure 7 As shown, the combined adjustable elastic sealing disc high temperature and high pressure safety valve of the present invention includes a valve body 1, a valve seat 2, a cooling fin 28, a valve stem 24, a valve cover 37 and a bonnet 44, the top, bottom and There are connection ports on the sides, the valve seat 2 extends upwards into the valve body 1 from the connection port at the bottom of the valve body 1, the connection port on the top of the valve body 1 is connected to the lower end of the cooling fin 28, and the upper end of the cooling fin 28 is connected to the valve cover 37 The lower end is connected, the bonnet 44 is set on the upper end of the bonnet 37, the valve stem 24 is located in the bonnet 37, the cooling fin 28 and the valve body 1 from top to bottom, and the valve stem 24 extends into the valve through the connection port on the top of the valve body 1. In the body 1, the lower end of the valve stem 24 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com