A rapid steam forming device for decorative panels

A decorative panel and molding device technology, applied in the field of rapid steam molding device, can solve the problems of low production efficiency, low qualification rate, increased manufacturing cost, etc., and achieve the effects of reducing molding time, saving human resources, and reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

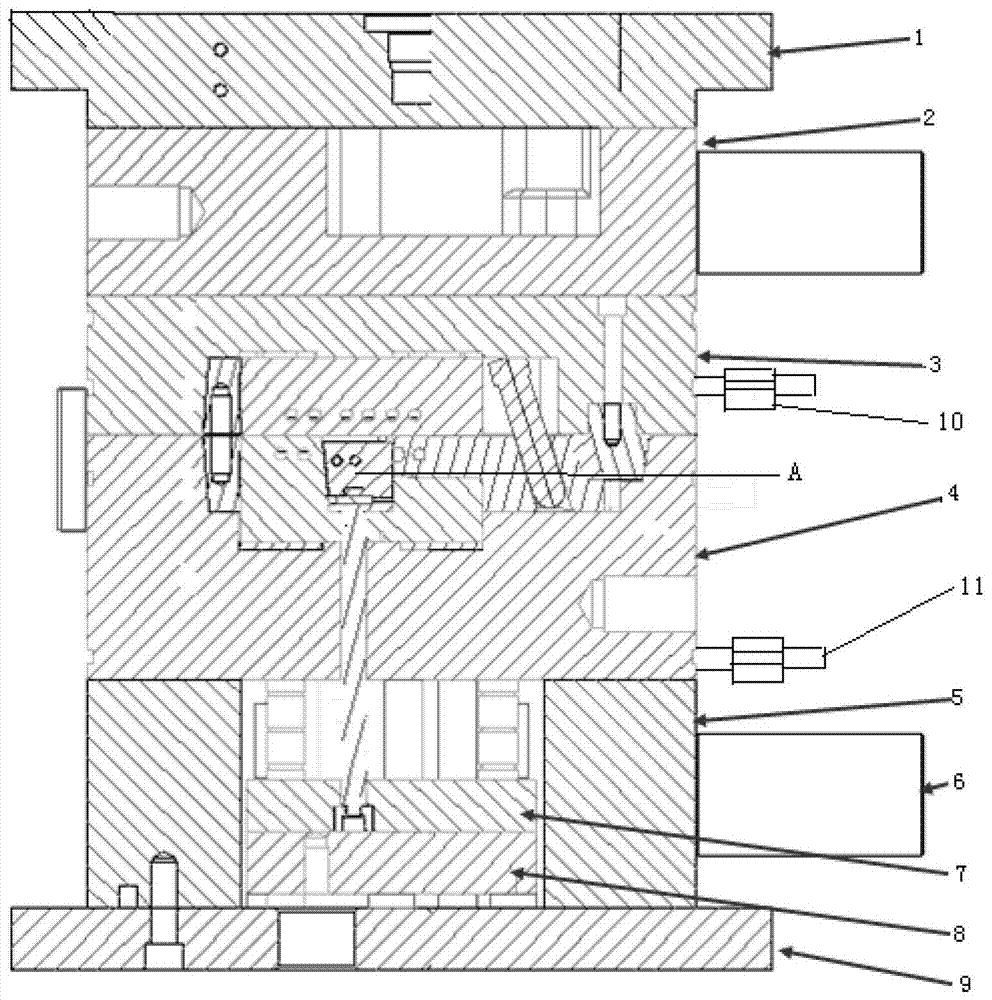

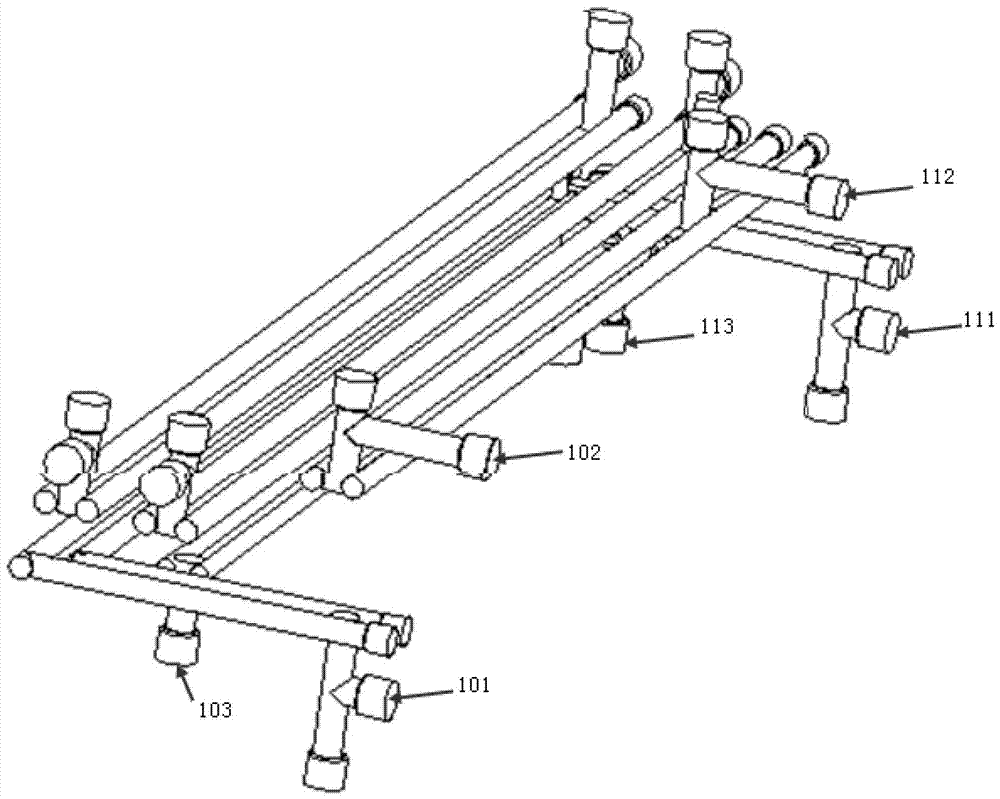

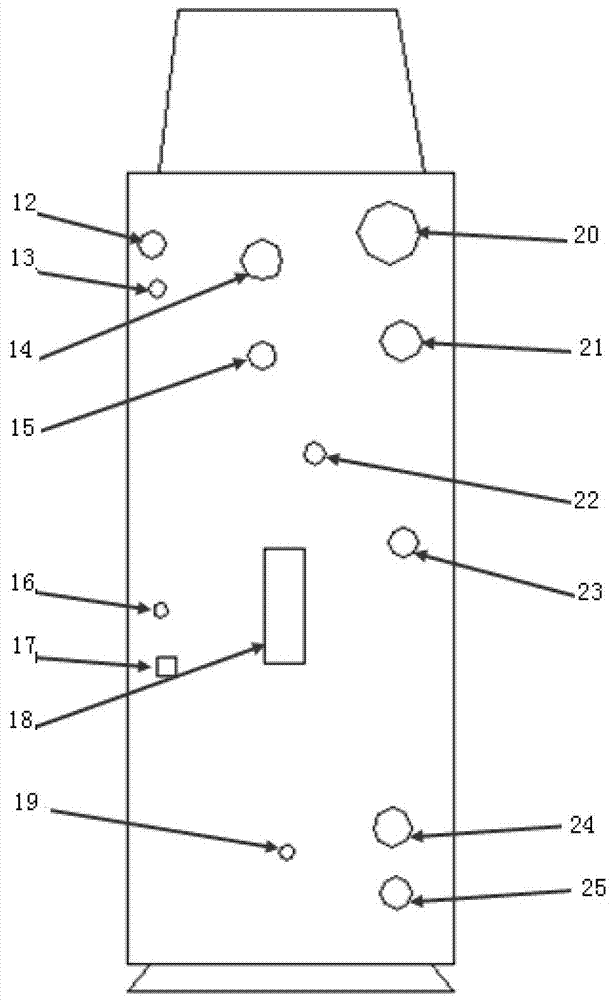

[0022] Such as Figure 1~3 As shown, a rapid steam forming device for a decorative panel, the device includes an injection mold and a steam forming machine device, the injection mold is provided with an inlet and outlet waterway, and the inlet and outlet waterway is connected to the steam forming machine device through a pipeline; the injection molding The mold includes an upper mold and a lower mold. The upper mold is composed of an I-shaped plate 1, a splitter plate 2 and an A plate 3 arranged sequentially from top to bottom. The lower mold is composed of a B plate 4, a square iron 5, and a foot 6. The upper needle plate 7, the bottom needle plate 8 and the bottom plate 9 are composed, wherein the A plate 3 is provided with a water outlet pipe 10, and the B board 4 is provided with a water inlet pipe 11; The water inlet pipe 11 is connected to the steam molding machine device; the water inlet and outlet waterways include three groups of parallel water inlet waterways (water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com