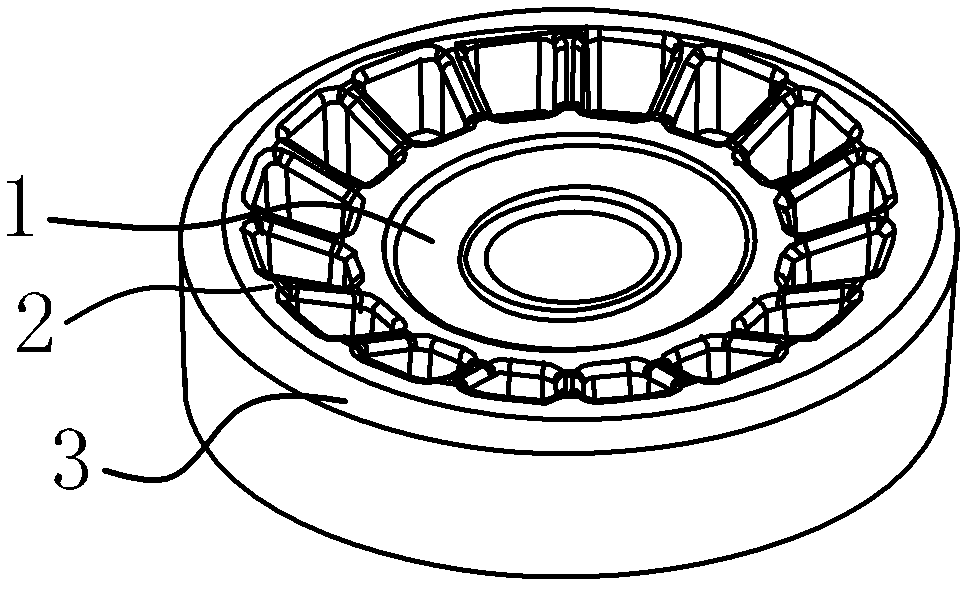

Method for manufacturing escalator roller

A production method and technology of rollers, which are applied in the mechanical field, can solve the problems of high assembly efficiency and assembly difficulty, unsatisfactory adhesion, etc., and achieve the effects of improving quality, improving connection firmness, and eliminating weld lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

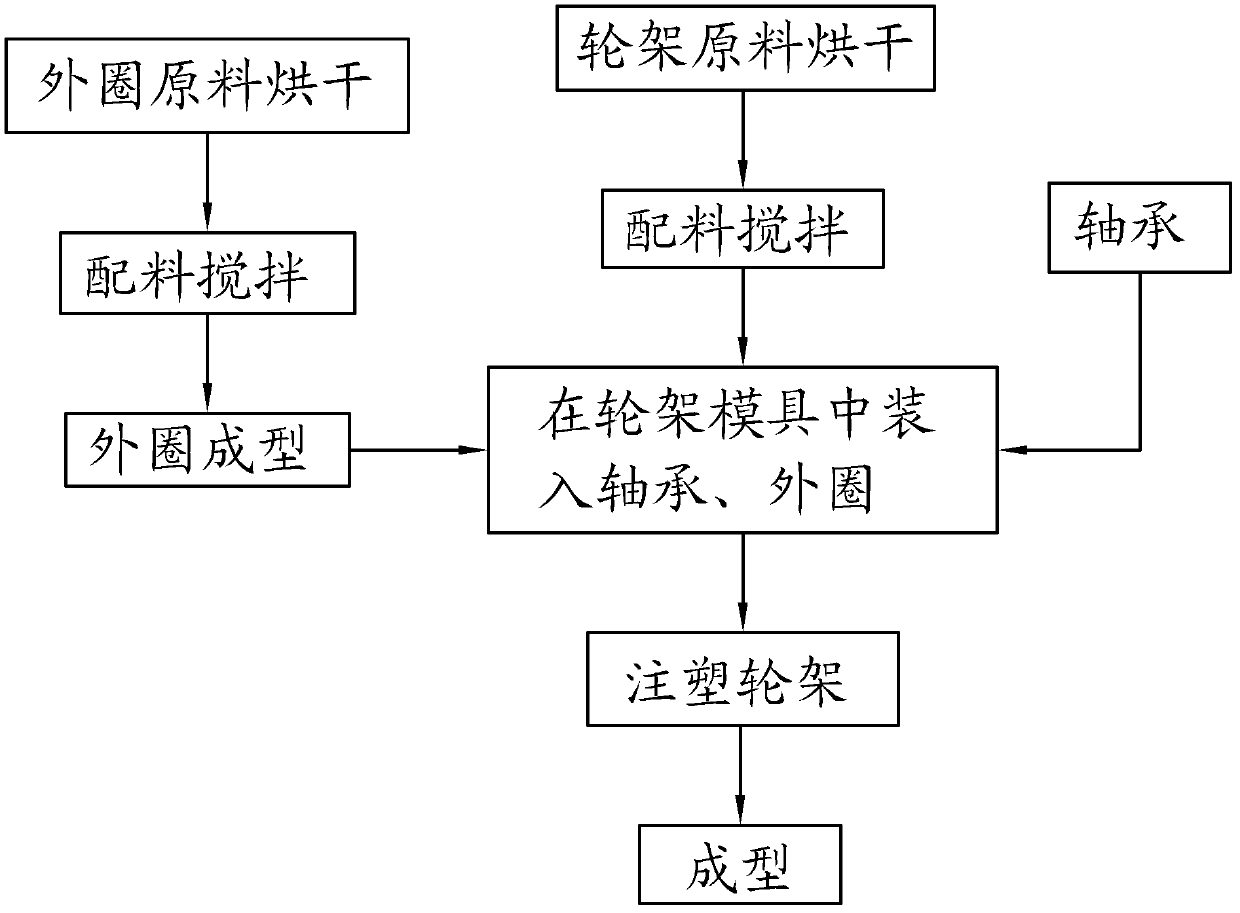

Method used

Image

Examples

Embodiment 2

[0034]Example 2 is basically the same as Example 1, the difference is that the contact time between two adjacent strands of viscous liquid wheel frame materials is controlled within 10 seconds, the temperature is 275°C and the pressure is 130MPa until the weld line of the two strands is two The ends are fully fused.

Embodiment 3

[0036] Example 3 is basically the same as Example 1, the difference is that the contact time between two adjacent viscous liquid wheel frame materials is controlled within 7 seconds, the temperature is 277°C and the pressure is 100 MPa until the weld line of the two materials is two The ends are fully fused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com