A kind of polyolefin reinforced material and preparation method thereof

A reinforced material and polyolefin technology, applied in the field of polyolefin reinforced materials and its preparation, can solve the problems such as the inability to greatly increase the strength of weld lines, reduce the formation of pores and micro-cracks, improve the degree of melt fusion, and the strength of weld lines Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

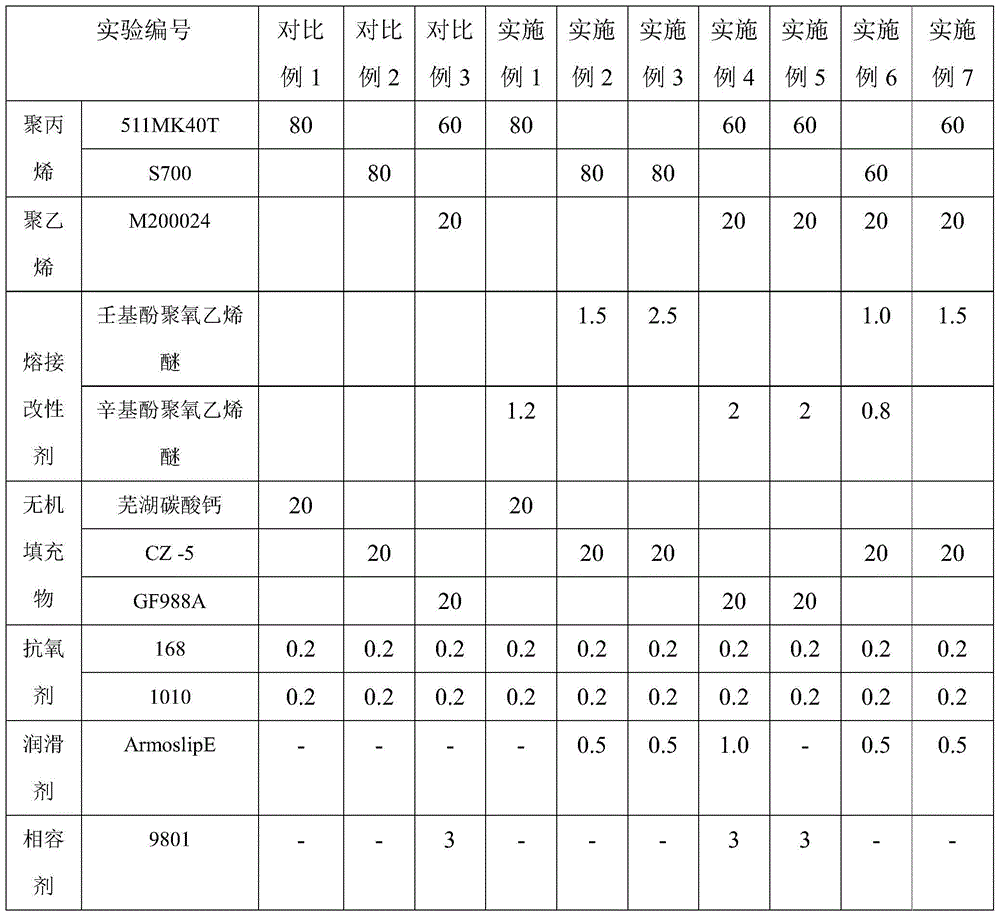

Examples

Embodiment 8

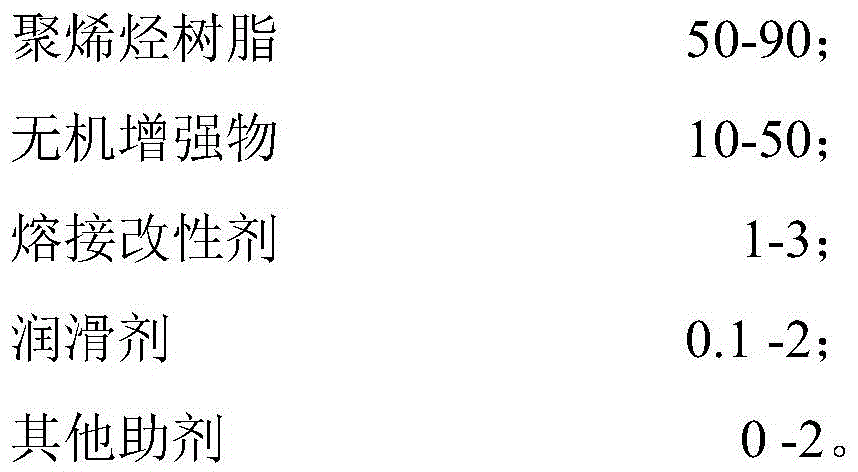

[0038] A polyolefin reinforced material, comprising the following components in parts by weight:

[0039]

[0040] Welding modifiers are selected from the group consisting of compound; in the above molecular formula, R is a chain segment containing 12 carbons, and the value of n is 5.

[0041] Among them, other additives include one or a combination of antioxidants, weather resistance agents, nucleating agents, antibacterial agents or compatibilizers.

[0042] The antioxidant is selected from the mixture of benzophenone functional group compound stabilizer and hindered phenol stabilizer with a weight ratio of 1:1;

[0043] The weather resistance agent is selected from benzophenone compounds;

[0044] The nucleating agent is selected from carboxylate metal salt compounds;

[0045] The compatibilizer is selected from maleic anhydride grafted polypropylene compounds.

[0046] A preparation method of polyolefin reinforced material, comprising the following steps:

[0047]...

Embodiment 9

[0049] A polyolefin reinforced material, comprising the following components in parts by weight:

[0050]

[0051] The inorganic reinforcement kaolin is treated with a silane coupling agent.

[0052] Welding modifiers are selected from the group consisting of In the above molecular formula, R is a chain segment containing 18 carbons, and n is 1.

[0053] Among them, other additives include one or a combination of antioxidants, weather resistance agents, nucleating agents, antibacterial agents or compatibilizers.

[0054] Antioxidant is selected from phosphite stabilizer or hindered amine stabilizer;

[0055] The weather resistance agent is selected from benzotriazole compounds;

[0056] The nucleating agent is selected from metal phosphate compounds;

[0057] The compatibilizer is selected from maleic anhydride grafted polypropylene compounds.

[0058] A preparation method of polyolefin reinforced material, comprising the following steps:

[0059] Produced by melt extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com