Label peeling device and labeling machine comprising same

A label and label stripping technology, which is applied in the field of label stripping equipment, can solve the problems of large footprint, small application range, and low efficiency, and achieve the effects of high degree of automation, short and compact structure, and low manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

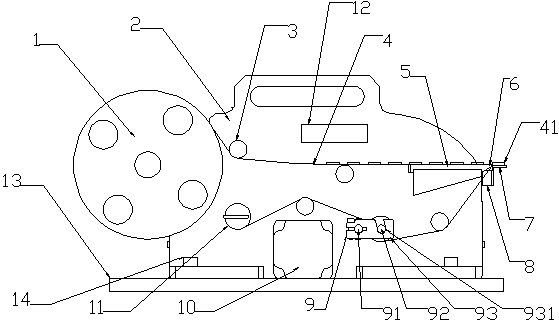

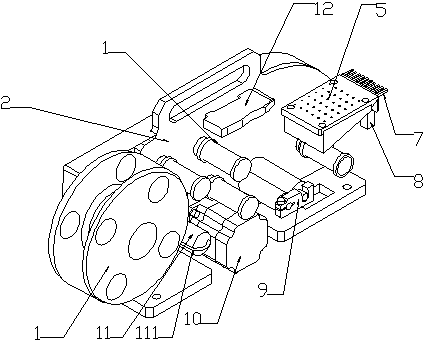

[0031] Such as Figure 1-2 As shown, a label stripping device includes a mounting frame 13 and a label stripping unit fixedly arranged on the mounting frame, wherein the label stripping unit is detachably connected to the mounting frame through positioning pins.

[0032] The label stripping unit includes: a mounting plate 2 and a transmission mechanism, a label stripping mechanism, a control mechanism and a driving mechanism respectively arranged on the mounting plate 2 . The conveying mechanism is used for conveying the label tape 4 , and includes an unwinding material rack 1 , a rewinding shaft 11 and a feeding assembly 9 vertically installed on the mounting plate. The unwinding rack includes a reel and a baffle (not shown in the figure), the label tape roll is set on the reel, and the baffle is used to block the label tape roll from moving back and forth in the lateral direction of the label tape; the rewinding shaft 11 is used for recycling For the strip backing paper who...

Embodiment 2

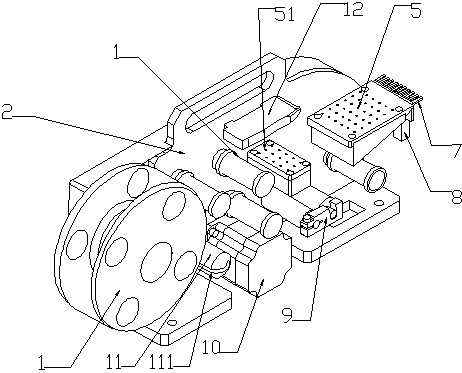

[0038] All the other are identical with embodiment 1, and difference is, as image 3 shown. There is also a vacuum suction cup in front of the label stripping knife plate to make the conveying path of the label tape more accurate; the positioning plate is a grid plate.

Embodiment 3

[0040] All the other are identical with embodiment 2, and difference is, as Figure 4 As shown, the label stripping device includes a mounting frame 13 and four label stripper units fixedly arranged on the mounting frame, wherein each label stripper unit is detachably connected to the mounting frame 13 through respective positioning pins 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com