Screw feeder device

A conveying device and worm technology, which is applied in the field of worm conveying devices, can solve the problems of container damage, occupation and fall, and achieve the effect of avoiding falling or falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

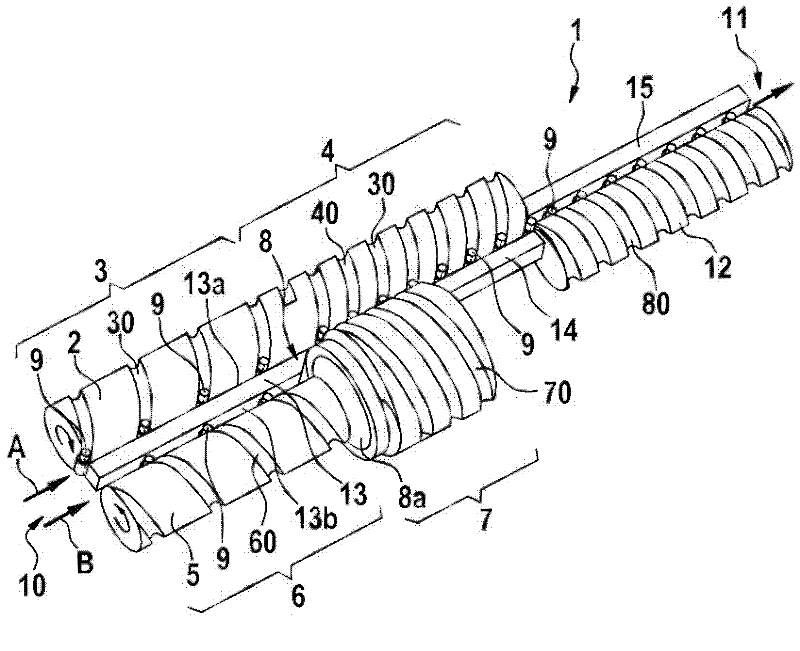

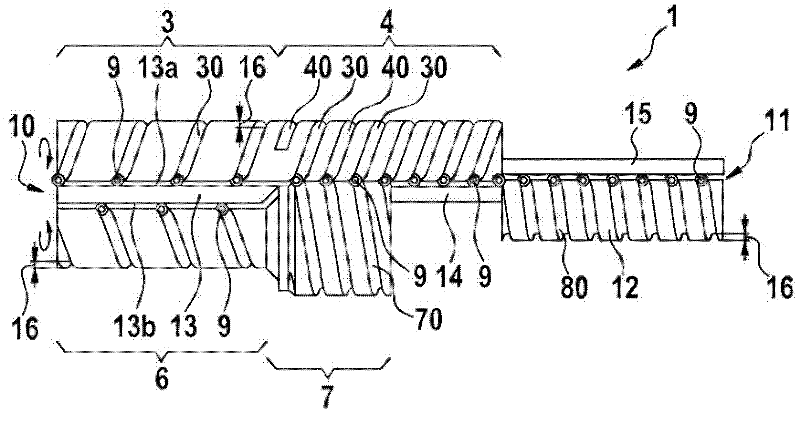

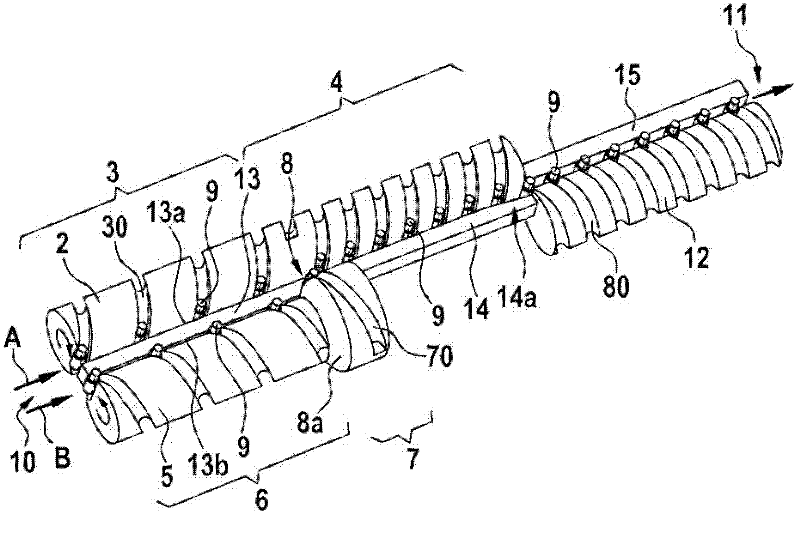

[0019] Refer below figure 1 and 2 The worm conveyor 1 according to a first preferred embodiment of the present invention will be described in detail.

[0020] as by figure 1 and 2 It can be seen that the screw conveyor 1 comprises a first input worm 2 with a first passage area 3 and a second passage area 4 . A first channel 30 is formed in the first channel region 3 , which also continues into the second channel region 4 . Also provided in the second channel region 4 is a second channel 40 which has the same pitch as the first channel 30 . The length of the first and second channel region 3 , 4 is here each half the overall length of the first input worm 2 . The first channel 30 and the second channel 40 are arranged on the same diameter of the first input worm 2 .

[0021] The screw conveyor 1 according to the first exemplary embodiment also includes a second input worm 5 with a third passage area 6 and a fourth passage area 7 . The third channel region 6 here has a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com