Single pump type sewage bioreaction treatment system

A sewage biological and treatment system technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult maintenance and treatment, expensive equipment, expensive equipment, etc., to achieve The effect of short and compact equipment structure, obvious competitive advantage, and shortened aeration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

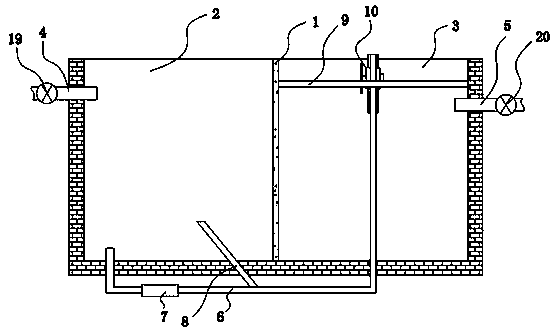

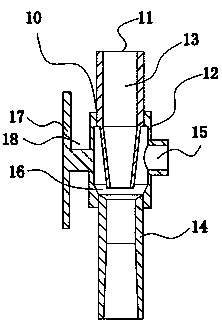

[0019] Refer to attached figure 1 with 2 , the single-pump sewage biological reaction treatment system in the figure includes A pool 2 and O pool 3 separated by a partition 1, and a waste water feed pipe 4 communicating with the inner cavity of A pool 2 and communicating with the inner cavity of O pool 3 The treated water drainage pipe 5, the inner cavity of the A pool 2 is communicated with the inner cavity of the O pool 3 through a suction pipe 6, and the suction pipe 6 is provided with a water pump 7; it is characterized in that: the suction pipe 6 The water inlet is located at the bottom of the inner chamber of the A pool 2, and a return pipe 8 is arranged at the bottom of the inner chamber of the A pool 2, and the water inlet end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com