Concentrated brine evaporation crystallization system

A technology of evaporation crystallization and concentrated brine, applied in the direction of heating water/sewage treatment, mechanical oscillation water/sewage treatment, etc., can solve the problems of scaling on the membrane surface, large dosage of antiscalant, poor economy, etc., to improve evaporation capacity, efficiency improvement, and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

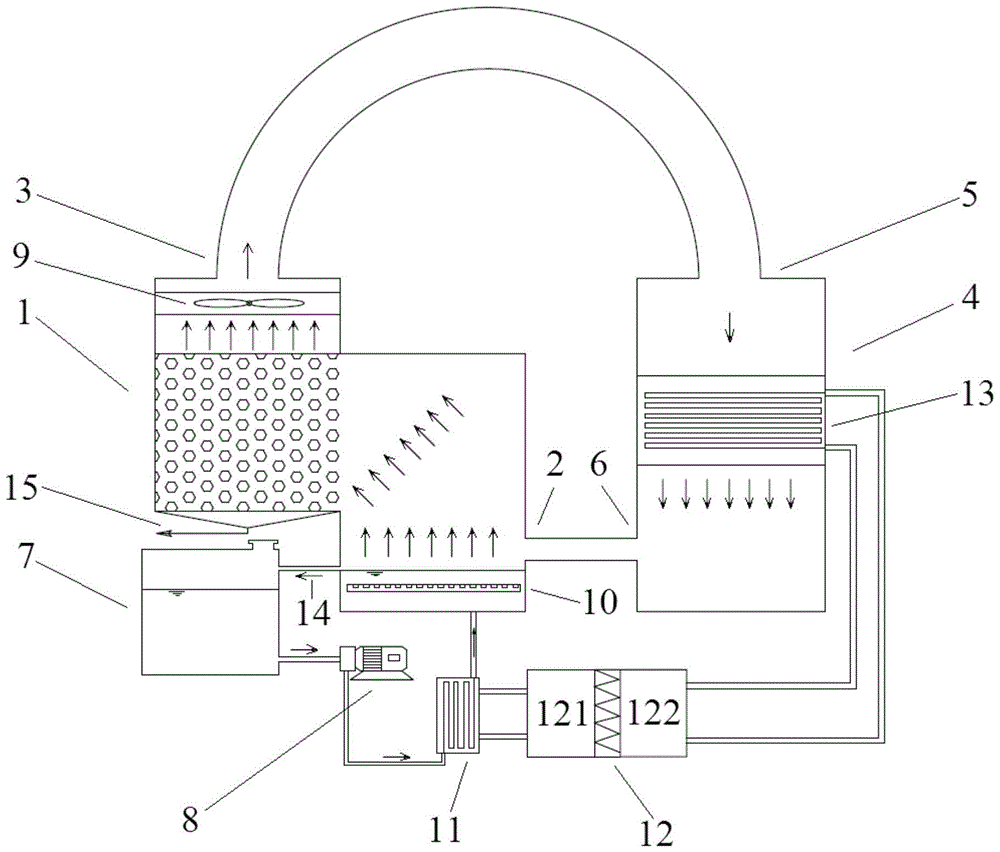

[0020] Now describe concentrated brine evaporation crystallization system of the present invention with reference to accompanying drawing. It should be noted that the concentrated brine involved in the present invention is a concentrated brine with a conductivity > 5000 μs / cm and a TDS (total dissolved solids) > 4000 mg / l.

[0021] Such as figure 1 Shown is a schematic structural view of the concentrated brine evaporation and crystallization system of the present invention, which includes an evaporation chamber 1 , a condensation chamber 4 and a concentrated brine tank 7 . Wherein, the evaporation chamber 1 has a first inlet 2 and a first outlet 3, and the condensation chamber 4 has a second inlet 5 and a second outlet 6, and the first inlet 2 of the evaporation chamber 1 communicates with the second outlet 6 of the condensation chamber 4 ; And the first outlet 3 of the evaporation chamber 1 communicates with the second inlet 5 of the condensation chamber 4, thereby construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com