Application and preparation method of nanometer metal composite oxide bismuth tungstate

A technology of composite oxides and nano-metals, applied in the field of nano-materials, can solve problems such as poor compatibility of propellant components, poor chemical stability, and environmental pollution by lead elements, so as to reduce the pressure index, facilitate industrial production, and synthesize The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Utilize commercially available nanometer metal composite oxide bismuth tungstate, particle diameter 50~100nm, add in the solid double-base propellant of main body with nitrocellulose / nitroglycerin with 2% addition amount, carry out propellant burning rate measurement, the result It shows that it has a catalytic combustion effect.

Embodiment 2

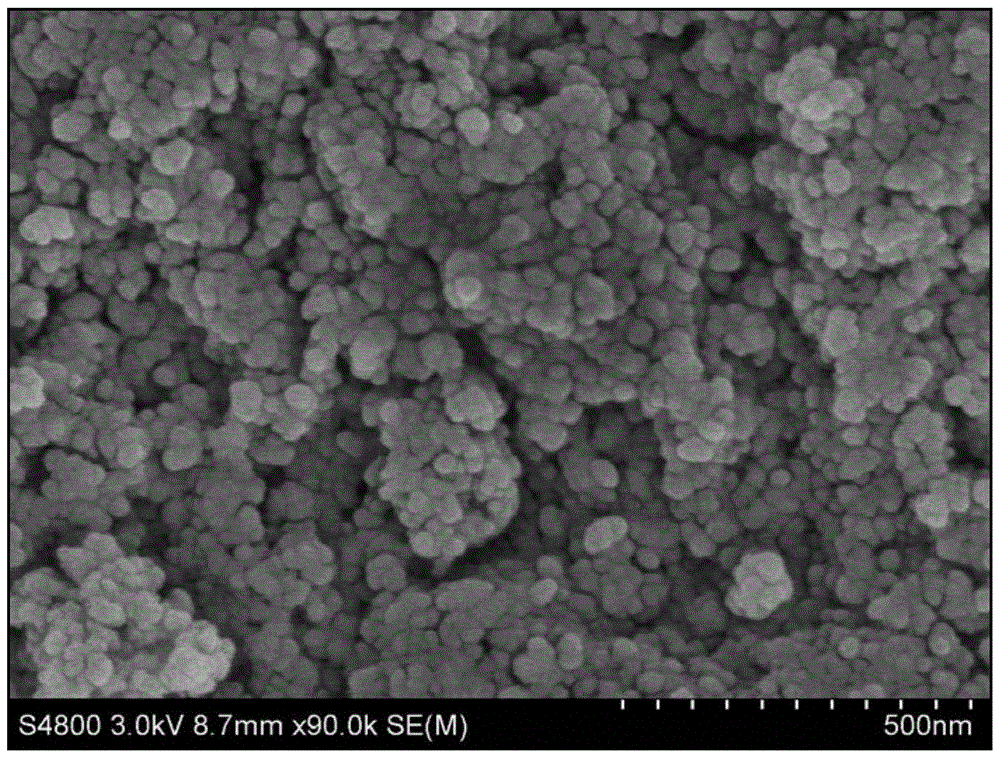

[0037] 5mmol (2.43g) Bi(NO 3 ) 3 ·5H 2 O and 2.5mmol (0.824g) NaWO 4 2H 2 O was dissolved in 20 mL of 10% dilute nitric acid solution and 20 mL of deionized water respectively, and the two solutions were mixed and stirred for 30 min; after mixing evenly, the pH was adjusted to 11 with 10% NaOH solution, and the solution became a suspension For the turbid solution, continue to stir for 1 hour; transfer the suspension to a 50mL autoclave and place it in a constant temperature drying oven at 160°C for 20 hours; centrifuge the precipitate obtained after the reaction, wash it with distilled water and ethanol, and dry it in vacuum at 80°C to obtain the target The product is bismuth tungstate. Yield 84%.

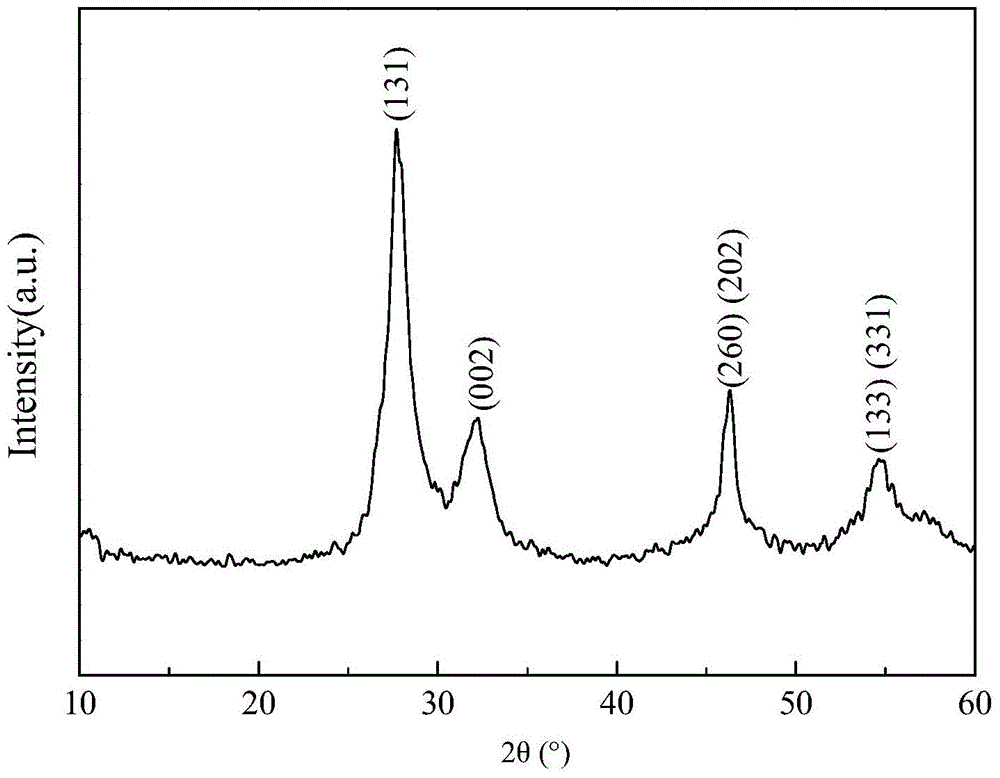

[0038] figure 1 It is the XRD spectrum of the bismuth tungstate of the present invention, and the XRD results show that the crystal phase of the nanocomposite metal oxide bismuth tungstate has a high purity and belongs to the orthorhombic tungstobismuth mineral structure (JCP...

Embodiment 3

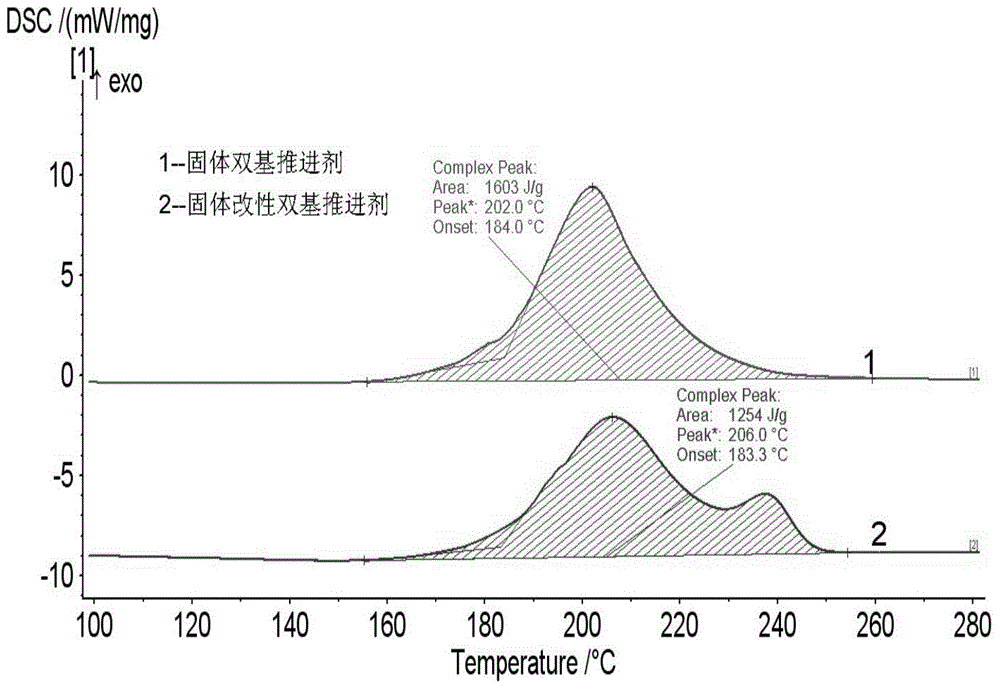

[0041] The nano-metal composite oxide bismuth tungstate synthesized by the method in Example 1 is added to the nitrocellulose / nitroglycerin solid double-base propellant and the nitrocellulose / nitroglycerin modified double-base propellant respectively with an additional amount of 2%. In the propellant, the DSC measurement was carried out to obtain image 3 The results shown show that the decomposition peak temperatures of solid double-base and modified double-base propellants added with nano-metal composite oxide bismuth tungstate are 202.0°C and 206.0°C, respectively, and the total heat release is 1603J / g and 1254J / g, respectively. High heat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com