Preparation method of core-shell-shaped nano composite metal oxide

A nano-composite, oxide technology, applied in chemical instruments and methods, iron compounds, manganese oxide/manganese hydroxide, etc., can solve the problem of low catalytic performance, achieve simple synthesis method, improve the excellent functional properties of particles, and improve catalytic performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

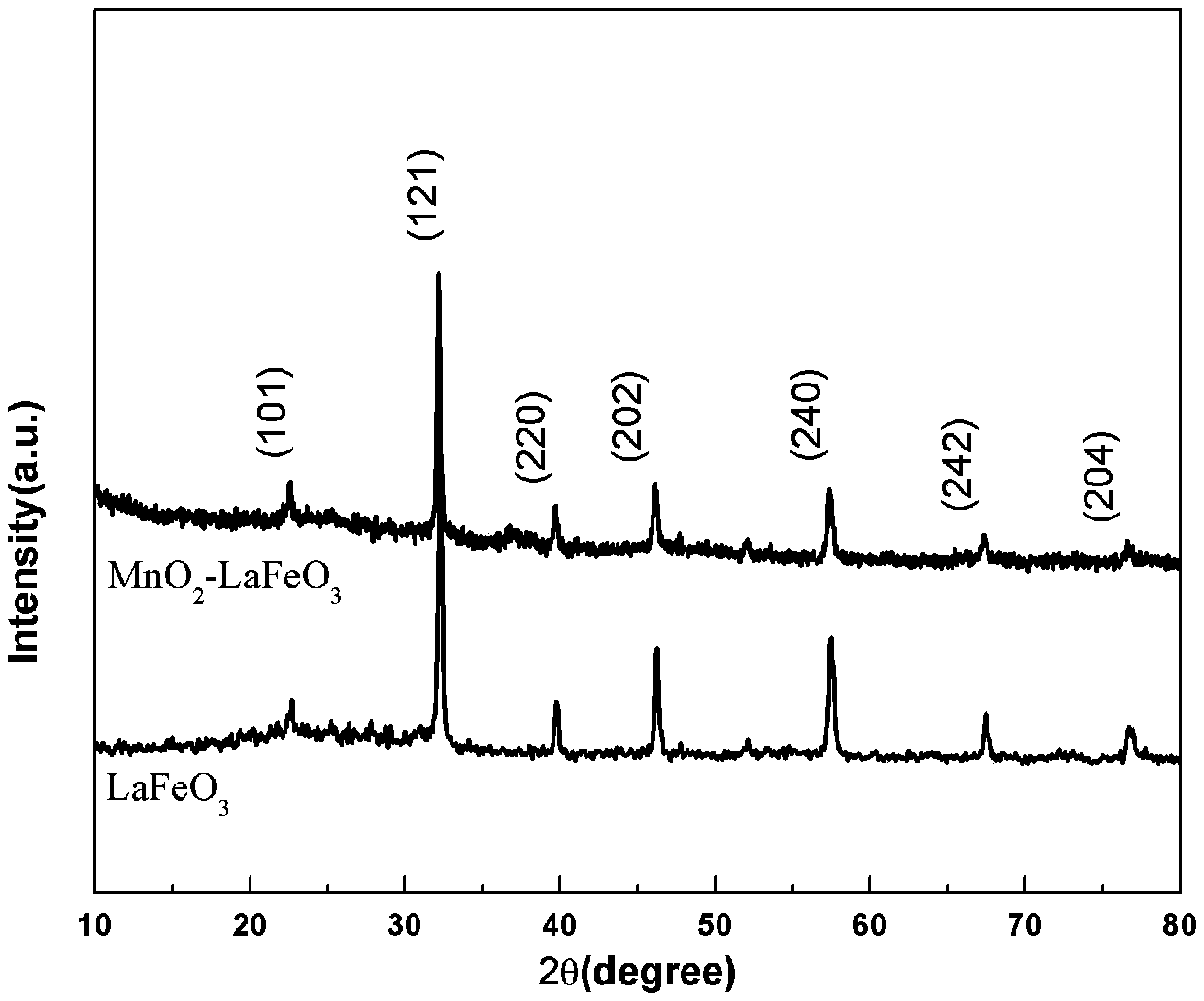

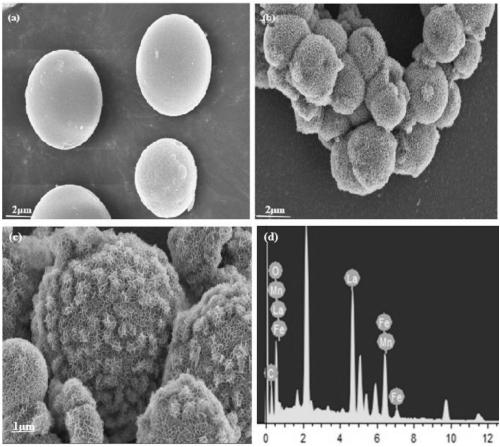

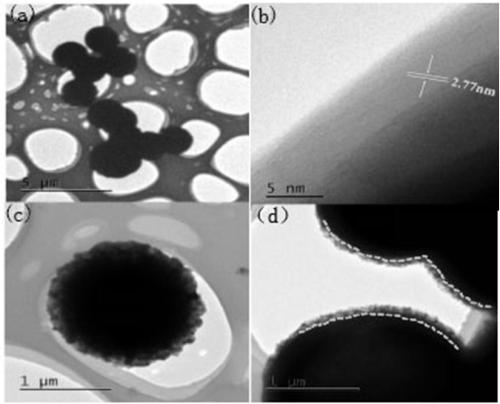

[0030](1) Dissolve 1.948g of lanthanum nitrate hexahydrate and 1.818g of ferric nitrate nonahydrate in a mixed solution of 90mL of ethanol and water (volume ratio of ethanol to water: 2:1), after vigorous stirring, add 0.08mol citric acid, Continue to stir until completely dissolved, then transfer the mixed solution to a polytetrafluoroethylene high-pressure reactor, react at 180°C for 24 hours, wash the precipitated product with ethanol and deionized water, dry to obtain a light green powder, and calcinate at 800°C for 4 hours to obtain iron Lanthanum acid powder.

[0031] (2) Disperse 100 mg of the obtained lanthanum ferrite in 30 mL of deionized water and sonicate for 1 h.

[0032] (3) Dissolve 0.142g of potassium permanganate in the above solution and stir for 1h.

[0033] (4) Put it in a 50mL hydrothermal kettle and react at 160°C for 12h.

[0034] (5) The precipitated product obtained from the reaction is repeatedly washed with ethanol and deionized water, and dried to...

Embodiment 2

[0043] Dissolve ferric nitrate and lanthanum nitrate in a mixed solvent of ethanol and water, then add citric acid, react in a high-pressure reactor at 180°C for 24 hours, filter and calcinate at 800°C for 6 hours to obtain lanthanum ferrite; among them, ferric nitrate The ratio of the amount of substance to lanthanum nitrate is 1:1. The volume ratio of ethanol and water in the mixed solvent of ethanol and water is 2:1. The ratio of lanthanum nitrate to the mixed solvent of ethanol and water is 1.948g:90mL. The ratio of lanthanum nitrate to citric acid is 1.948g:0.08mol.

[0044] Disperse the obtained lanthanum ferrite in deionized water, add potassium permanganate, react in a hydrothermal reaction kettle at 180° C. for 12 hours, wash and dry to obtain a core-shell structure core-shell nano-composite metal oxide. Wherein, the ratio of lanthanum ferrite to deionized water is 100mg:30mL. The mass ratio of lanthanum ferrite to potassium permanganate is 1:1.5.

Embodiment 3

[0045] Example 3 Dissolve ferric nitrate and lanthanum nitrate in a mixed solvent of ethanol and water, then add citric acid, react in an autoclave at 190°C for 24 hours, filter and calcinate at 900°C for 4 hours to obtain lanthanum ferrite; , the ratio of the amount of iron nitrate to lanthanum nitrate is 1:1.2. The volume ratio of ethanol and water in the mixed solvent of ethanol and water is 2.1:1. The ratio of lanthanum nitrate to the mixed solvent of ethanol and water is 1.948g:90mL. The ratio of lanthanum nitrate to citric acid is 1.948g:0.08mol.

[0046] Disperse the obtained lanthanum ferrite in deionized water, add potassium permanganate, react in a hydrothermal reaction kettle at 170° C. for 18 hours, wash and dry to obtain a core-shell structure core-shell nano-composite metal oxide. Wherein, the ratio of lanthanum ferrite to deionized water is 100mg:30mL. The mass ratio of lanthanum ferrite to potassium permanganate is 1:1.42.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com