Preparation method and application of nitrated chitosan/go/n-ti composite material

A technology of nitrated chitosan and composite materials, which is applied in the field of preparation of nitrated chitosan/GO/n-Ti composite materials, can solve problems that need to be improved, achieve rapid and stable combustion, improve safety performance, and burn full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Ultrasonic disperse 0.7g of n-Ti powder (100nm ~ 150nm) in 15mL of acetone solution to obtain n-Ti acetone suspension; stir and dissolve 0.1g of nitrated chitosan in 15mL of acetone solution to obtain nitrated chitosan Acetone solution; 4.0 mg of GO was ultrasonically dispersed in 15 mL of ethanol solution to obtain an ethanol suspension of graphene oxide (GO).

[0037] Then the acetone suspension of n-Ti was added dropwise to the nitrated chitosan acetone solution, and after being uniformly mixed by acoustic resonance, the ethanol suspension of graphene oxide (GO) was added dropwise, and then uniformly mixed by acoustic resonance, centrifuged After filtration and vacuum freeze-drying, a brown powder is obtained, which is the high-energy nanocomposite nitrated chitosan / GO / n-Ti.

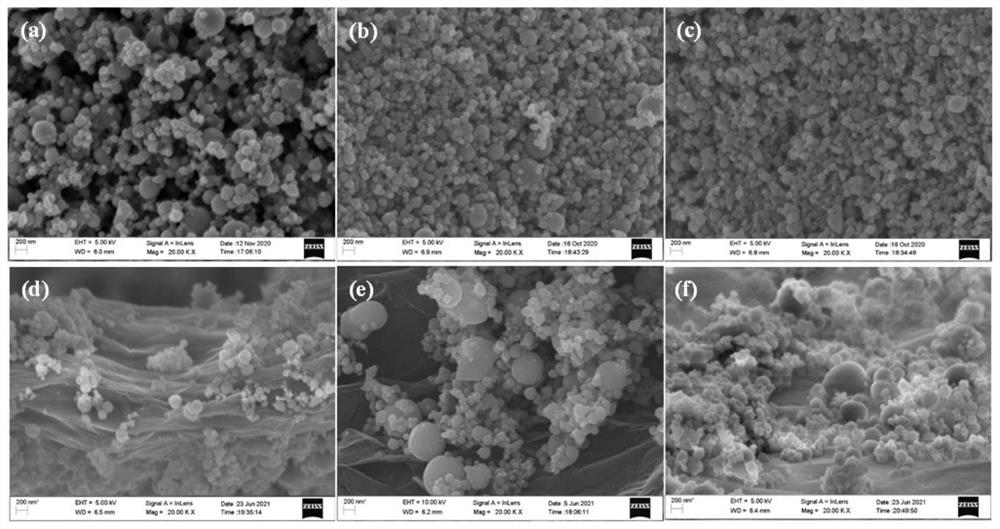

[0038] figure 1 Middle (d) is the SEM image of the nitrated chitosan / GO / n-Ti prepared in this example, and the results show that the n-Ti core-shell particles coated with nitrated chitosan are...

Embodiment 2

[0040] Ultrasonic disperse 0.7g of n-Ti in 15mL of acetone solution to obtain acetone suspension of n-Ti; stir and dissolve 0.1g of nitrated chitosan in 15mL of acetone solution to obtain acetone solution of nitrated chitosan; GO was ultrasonically dispersed in 15 mL of ethanol solution to obtain ethanol suspension of graphene oxide (GO).

[0041] Then the acetone suspension of n-Ti was added dropwise to the nitrated chitosan acetone solution, and after being uniformly mixed by acoustic resonance, the ethanol suspension of graphene oxide (GO) was added dropwise, and then uniformly mixed by acoustic resonance, centrifuged After filtration and vacuum freeze-drying, a brown powder is obtained, which is the high-energy nanocomposite nitrated chitosan / GO / n-Ti.

[0042] figure 1Middle (e) is the SEM picture of the nitrated chitosan / GO / n-Ti that this embodiment makes, and the result shows: the n-Ti core-shell particles coated with nitrated chitosan are successfully supported on the ...

Embodiment 3

[0045] Ultrasonic disperse 0.7g of n-Ti in 15mL of acetone solution to obtain an acetone suspension of n-Ti; stir and dissolve 0.1g of nitrated chitosan in 15mL of acetone solution to obtain a solution of nitrated chitosan in acetone; GO was ultrasonically dispersed in 15 mL of ethanol solution to obtain ethanol suspension of graphene oxide (GO).

[0046] Then the acetone suspension of n-Ti was added dropwise to the nitrated chitosan acetone solution, and after being uniformly mixed by acoustic resonance, the ethanol suspension of graphene oxide (GO) was added dropwise, and then uniformly mixed by acoustic resonance, centrifuged After filtration and vacuum freeze-drying, a brown powder is obtained, which is the high-energy nanocomposite nitrated chitosan / GO / n-Ti.

[0047] figure 1 Middle (f) is the SEM image of the nitrated chitosan / GO / n-Ti prepared in this example, and the results show that the n-Ti core-shell particles coated with nitrated chitosan are evenly loaded on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com