A cable tunnel multifunctional inspection shaft

A technology for cable tunnels and inspection wells, applied in the field of cable tunnels, can solve the problems of water accumulation, backflow, and low depth in cable tunnels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

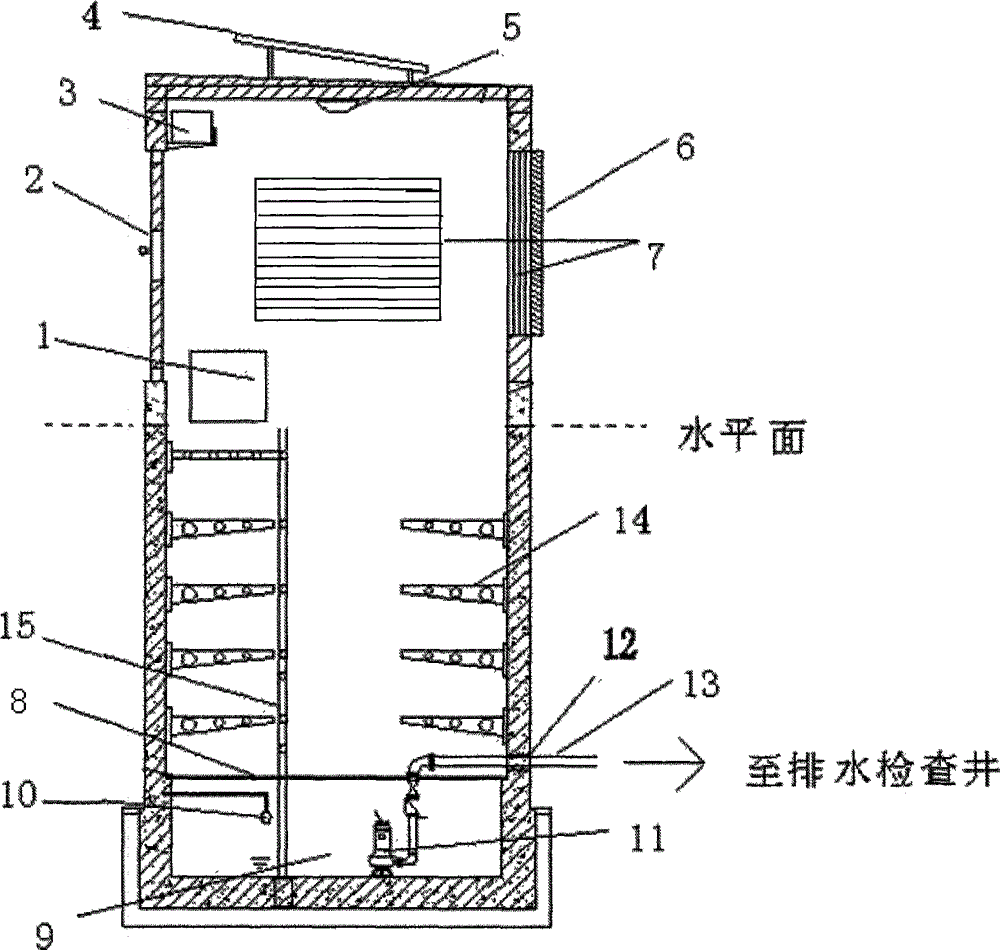

[0015] Such as figure 1 As shown, a cable tunnel multifunctional inspection well, including intelligent sewage control box 1, switch door 2, battery 3, solar panels 4, lamps 5, rain shutters 6, protective net 7, galvanized safety cover 8, A sump 9, a liquid level gauge 10, a submersible sewage pump 11, a flexible waterproof casing 12, a drainage pipe 13, a cable bracket 14, and a ladder 15. The intelligent sewage control box 1 is installed on one side of the upper house wall of the inspection well. The switch door 2 is set on the road surface of the upper house of the inspection well, the solar cell panel 4 is installed on the top of the upper house of the inspection shaft, the battery 3 is installed in the upper house of the inspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com