Rectification acceleration disc structure of range hood

A technology of range hood and disc structure, which is applied in the direction of oil fume removal, application, and household stoves, etc. It can solve the problems of uncertain cross-sectional area of oil fume passage, unstable effect of negative pressure smoke collection of smoke guide plate, etc., and achieve good noise reduction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

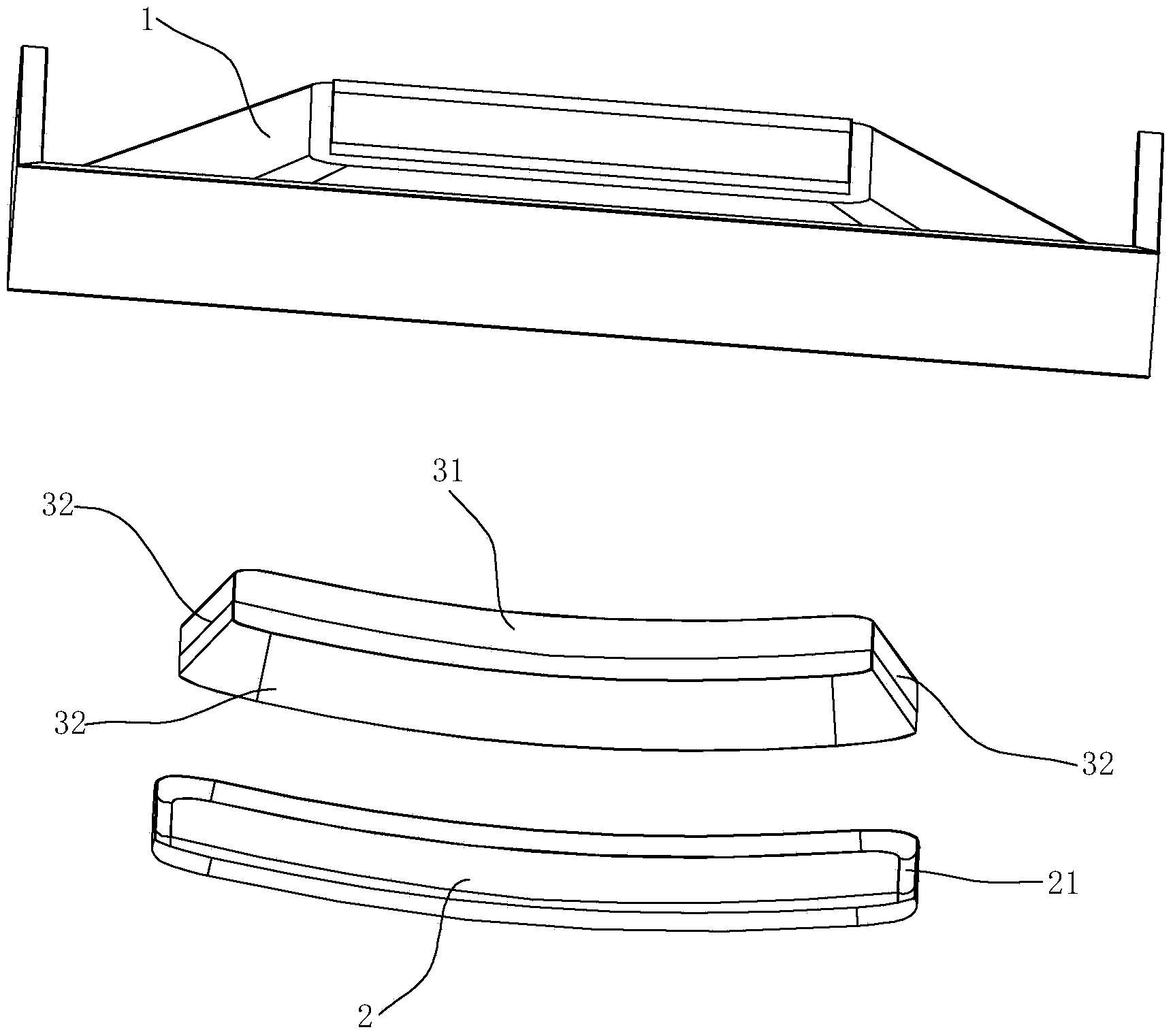

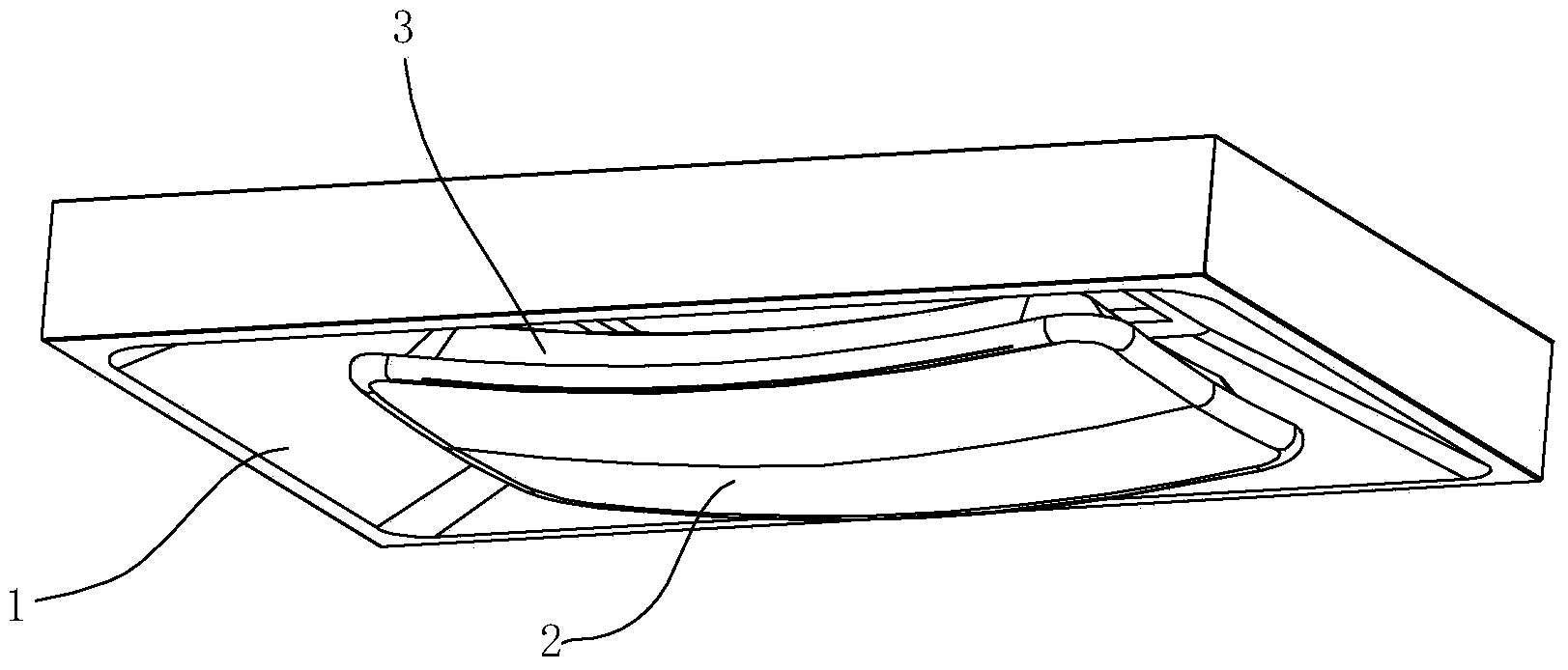

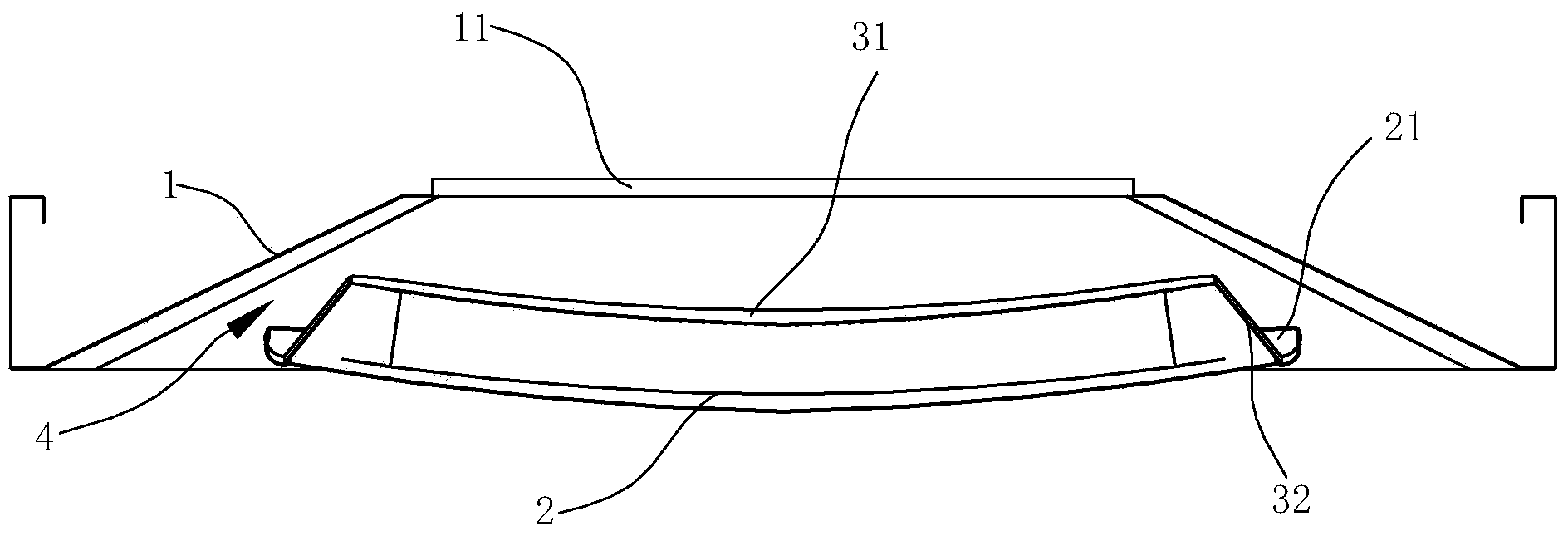

[0016] see Figure 1 ~ Figure 3 , a rectifying acceleration disk structure for a range hood, the range hood used includes a smoke collection hood 1, the smoke collection hood 1 is provided with an air inlet 11, facing the air inlet 11 and spaced from the smoke collection hood 1 There are rectifier plates 2.

[0017] The side of the rectifying plate 2 facing the smoke collecting hood 1 is provided with an acceleration disk 3 , and the acceleration disk 3 includes a bottom surface 31 and at least one side surface 32 located around the bottom surface 31 , in this embodiment, there are four sides. The acceleration plate 3 covers the rectifying plate 2 and can be fixed with the rectifying plate 2 by means of riveting or the like. Its bottom surface 31 is opposite to the smoke collecting hood 1 and has a certain gap to form a certain inlet distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com