A Dynamic Balancing Method for High Speed Rotor

A high-speed rotor and rotor technology, applied in static/dynamic balance testing, machine/structural component testing, measuring devices, etc., can solve problems such as low precision of unbalanced vibration extraction and high cost of dynamic balancing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

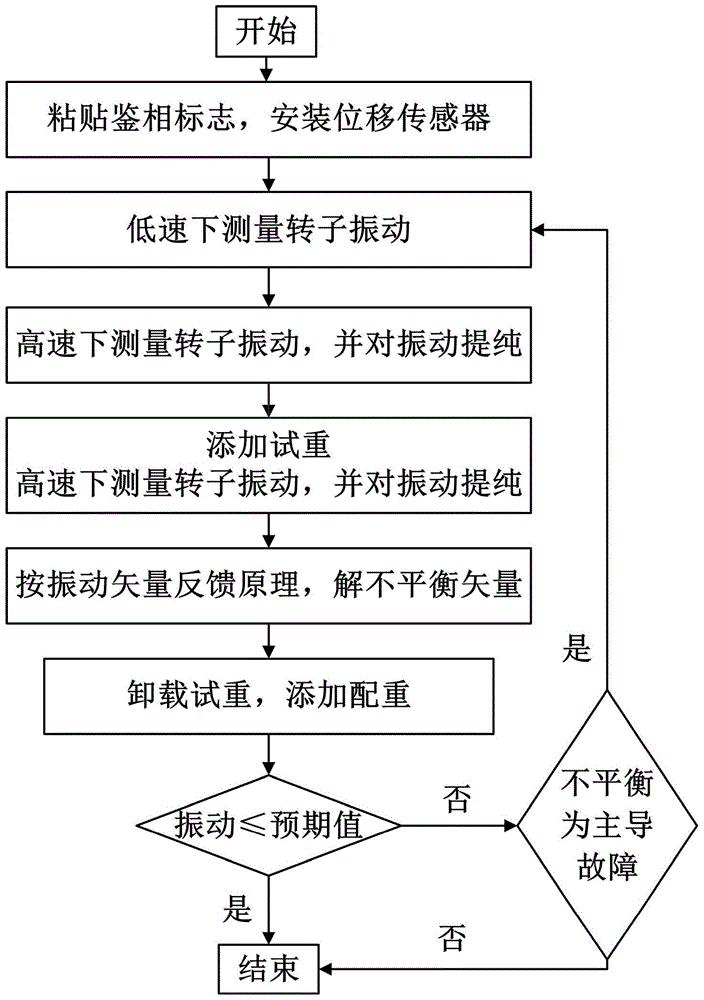

Method used

Image

Examples

Embodiment 1

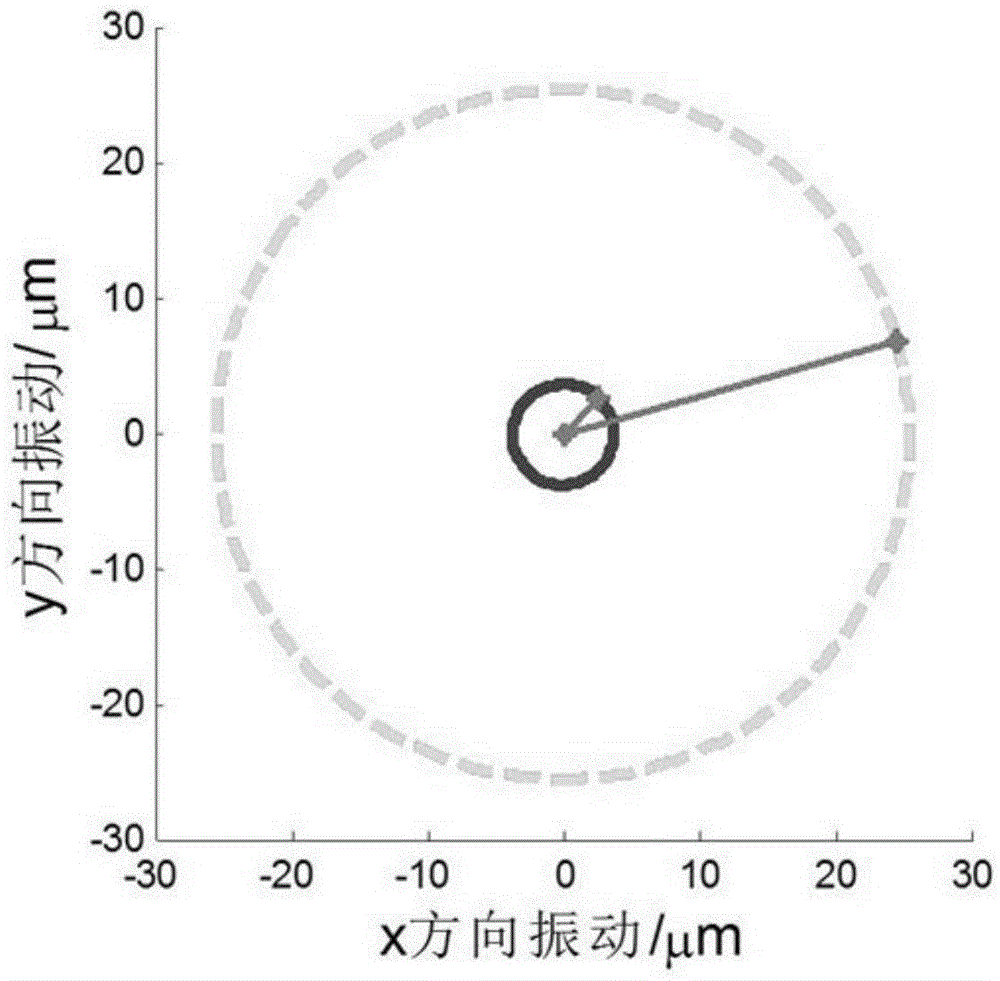

[0047] This embodiment mainly verifies the validity and accuracy of the present invention.

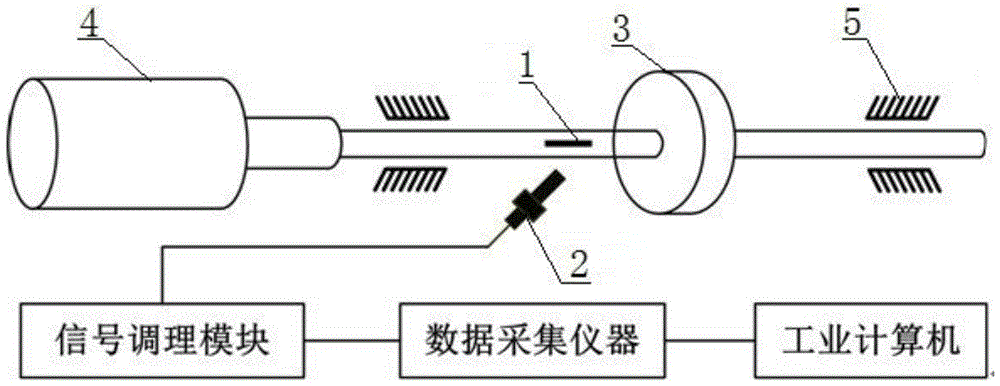

[0048] 1. Composition of dynamic balance experiment system

[0049] Such as figure 1 As shown, the unbalanced fault is simulated by the rotor experimental system to study the effectiveness of the dynamic balancing method of the present invention. The hardware part of the system mainly includes several major modules such as BentlyRK4 rotor test bench, eddy current displacement sensor 2, signal conditioning module, NI data acquisition module, and industrial computer. Among them, the rotor test bench is composed of three parts: the rotor connected to the motor 4, the bearing 5, and the mass disc 3. The eddy current displacement sensor 2 can test the radial vibration information of the rotor in real time, and the data acquisition module converts the analog signal representing the displacement information Convert it into a digital signal, and send it to an industrial computer for unbalanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com