Automobile embedded knob switch endurance test device

A technology of knob switch and durability test, which is applied in the field of automobiles, can solve the problems of difficulty in meeting the requirements of the size of the knob operating force, low degree of automation, and low work efficiency, so as to improve the degree of intelligence and test accuracy, and improve the degree of intelligence , Improve the effect of test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

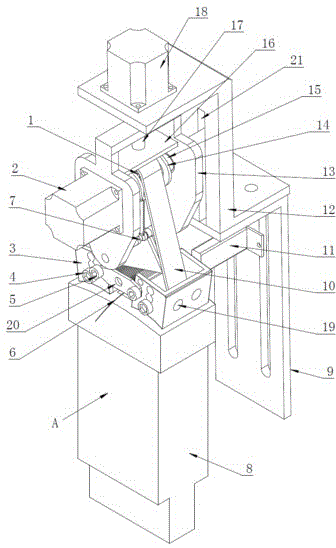

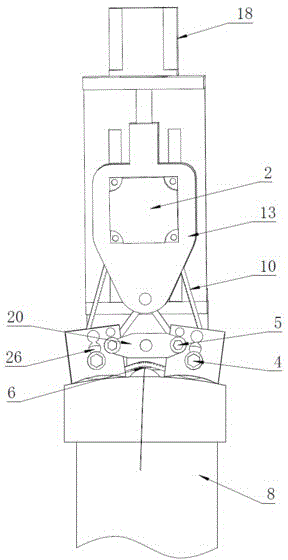

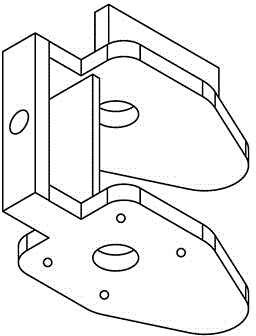

[0030] see Figure 1 to Figure 7 , the present invention mainly includes a driving gear 1, a test motor 2, a driven roller bracket 3, a strain gauge pressure sensor 6, an adaptive triangular bracket 7, a sensor bracket 9, a timing belt 10, a color sensor 11, an equipment bracket 12, an active Gear support 13, limit piece 14, leading screw limit plate 16, leading screw pair 17, pressing motor 18, fixed plate 20, vertical slide rail 21 and driven roller 26. The main components function as follows:

[0031] Compression motor 18: drives the screw pair 17 to rotate;

[0032] Lead screw pair 17: drive the driving gear bracket 13 to rise or fall through rotation;

[0033] Lead screw limiting plate 16: limit the rising height of the driving gear bracket 13, and prevent the lead screw from interfering with the synchronous belt;

[0034] Drive gear bracket 13: fix the drive gear 1 and the test motor 2, and its side has a dovetail slider matching the vertical slide rail 21 to ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com