A method for measuring residual flexural capacity of wooden beams in ancient buildings

A measurement method and technology of ancient buildings, applied in the field of wood science and engineering, can solve problems such as destructive tests, actual density, elastic modulus and bearing capacity errors, and achieve fast test operation, simple test operation, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

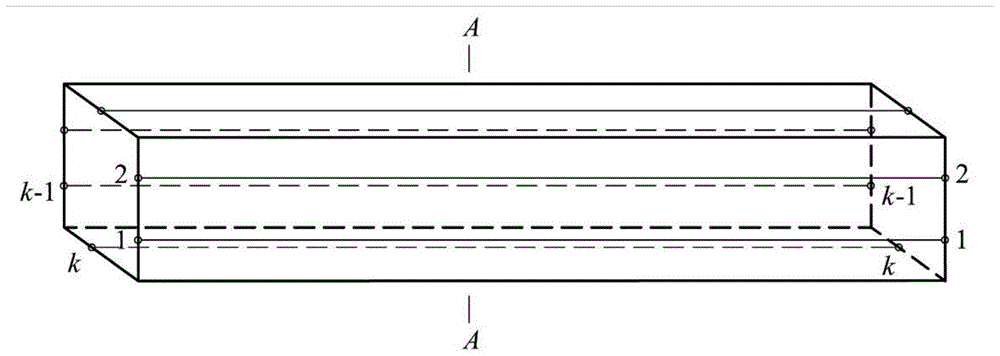

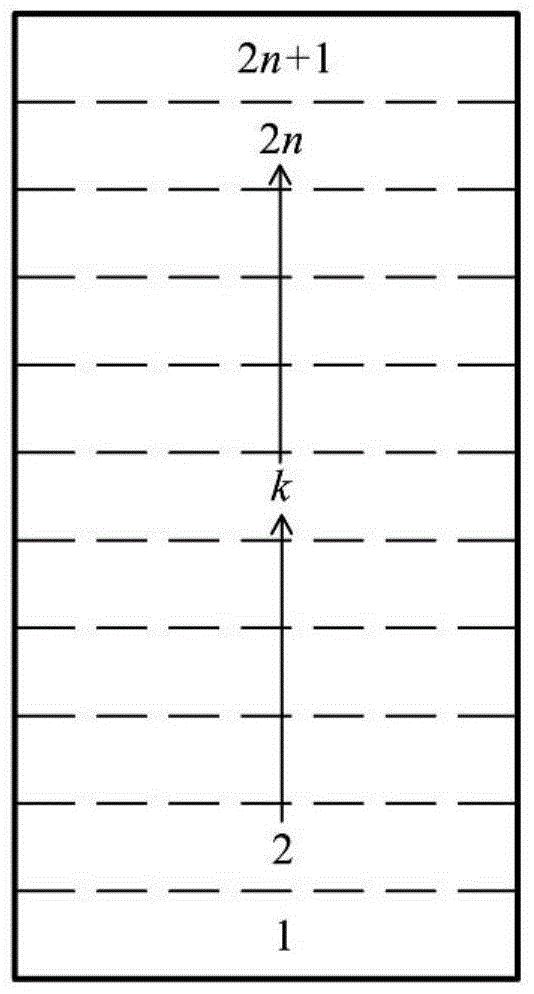

[0018] The remaining flexural bearing capacity measuring method of the ancient building wooden beam that the present invention proposes, comprises the following steps:

[0019] (1) Process the replaced damaged wooden components of the ancient buildings to be tested into standard small test pieces. The size of the standard small test piece is 20×20×300 mm. The physical and mechanical properties of the standard small test piece are tested to obtain the standard small test piece. The average value of micro-drilling resistance value F, stress wave propagation velocity v and bending strength f;

[0020] (2) Taking the average value of the above-mentioned micro-drilling resistance value and the propagation velocity of the stress wave as independent variables, carry out regression analysis on the above-mentioned bending strength, and obtain the fitting parameter values C and D: f=C+DFv 2 , in one embodiment of the present invention, fitting parameter values C=17.375, D=20.936: f=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com