Refrigeration cycle device

一种制冷循环、制冷剂的技术,应用在制冷机、制冷组件、制冷和液化等方向,能够解决制冷循环装置大型化、循环结构复杂化等问题,达到搭载性提高、循环结构简化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

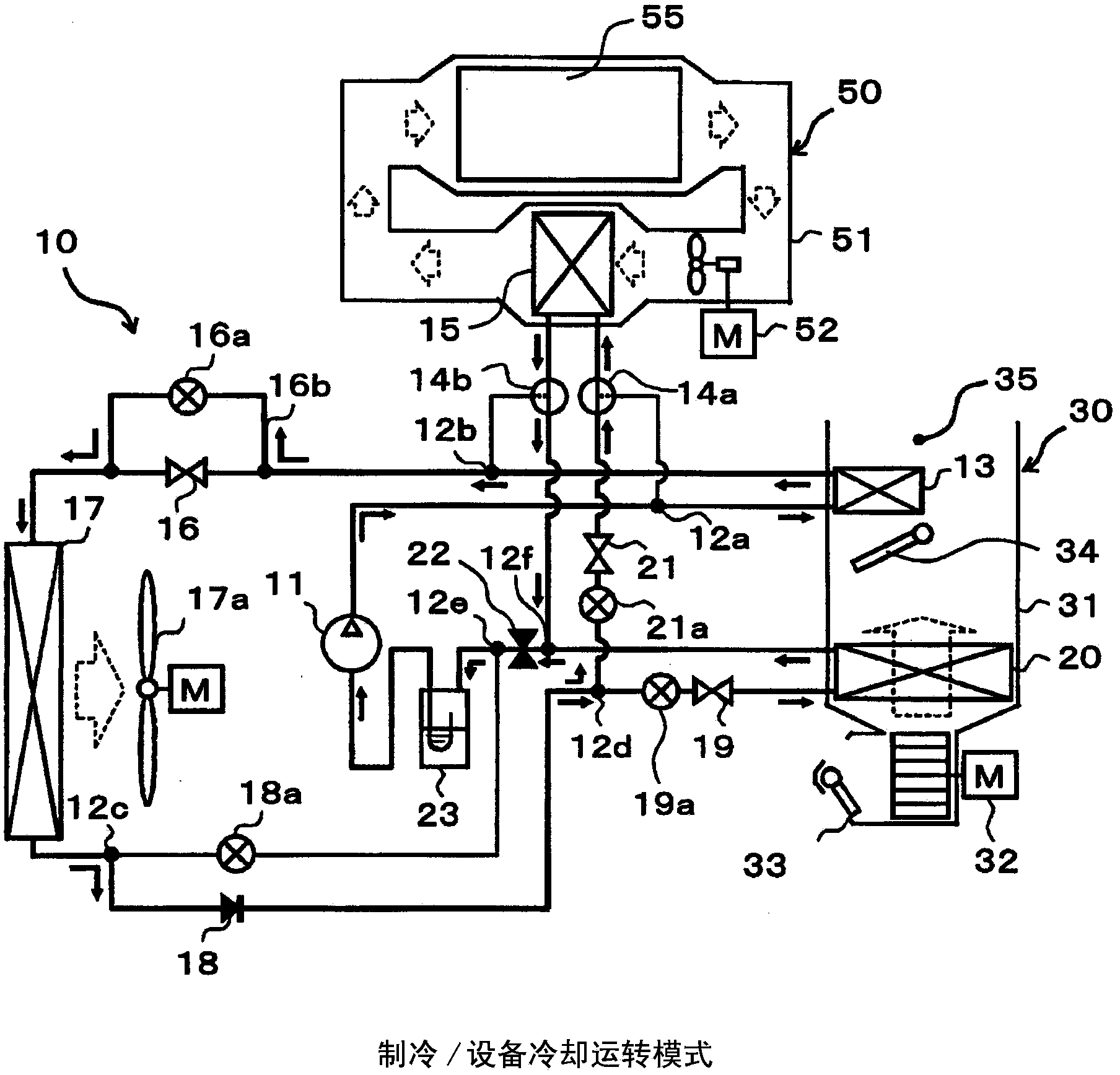

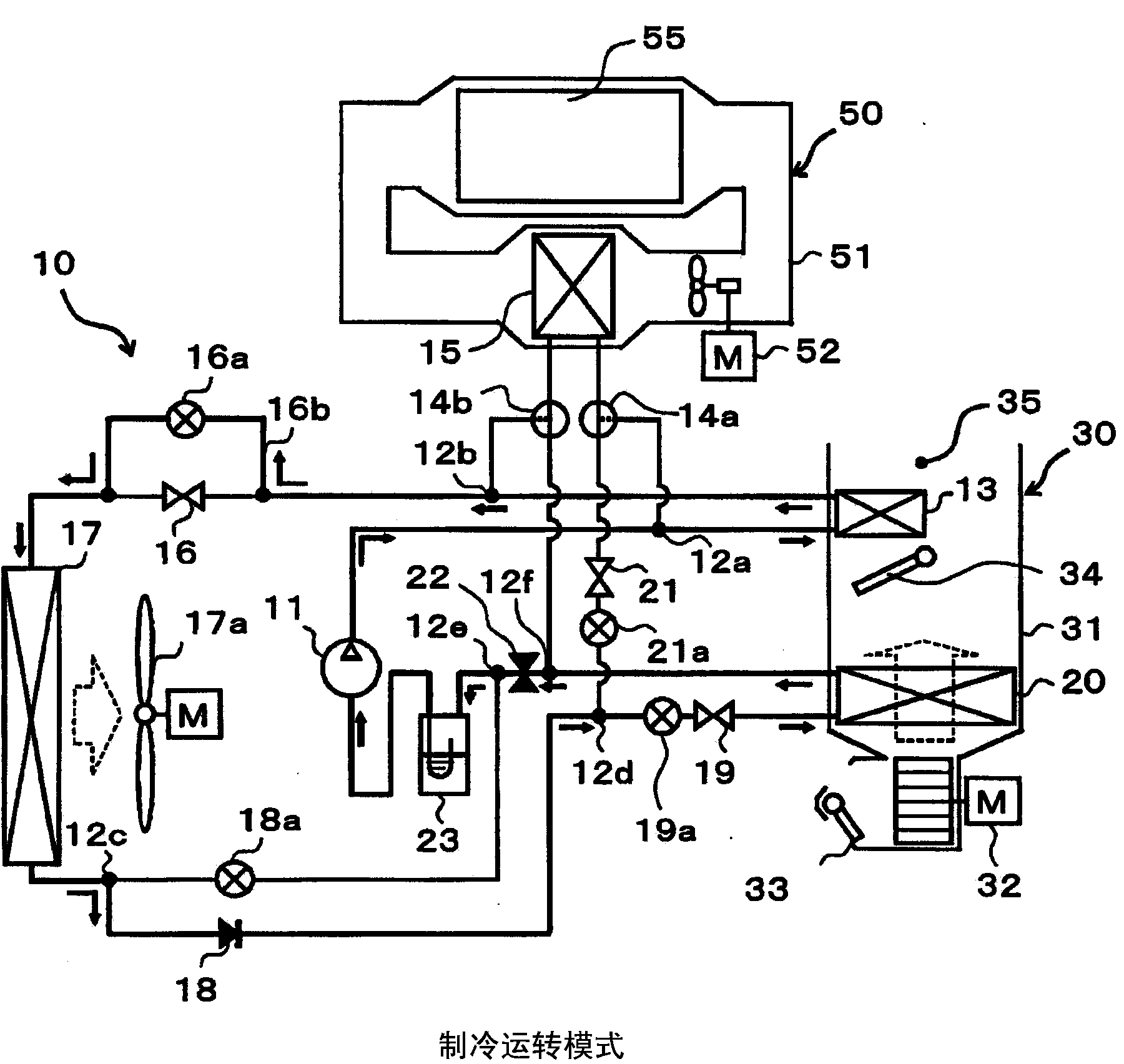

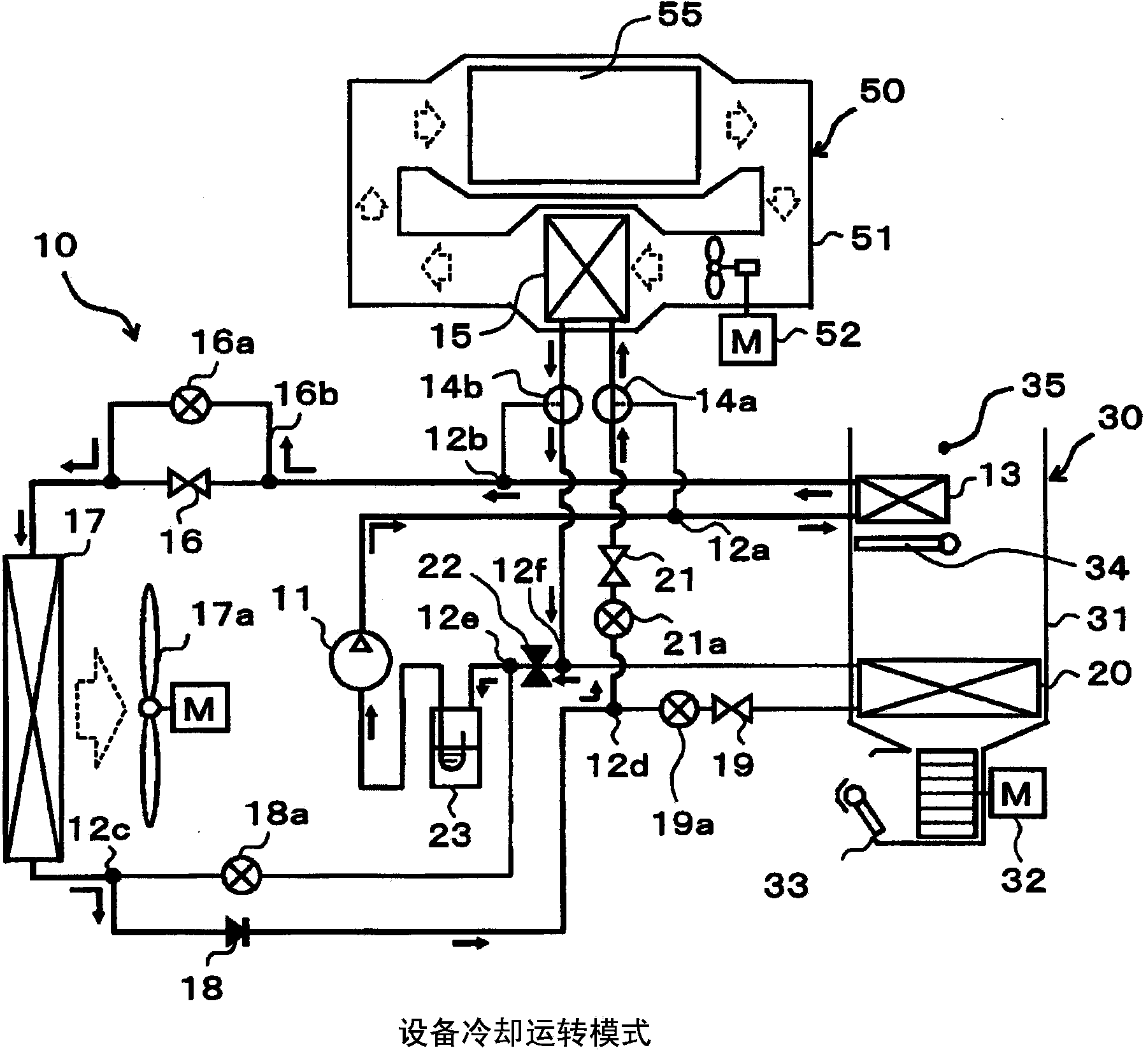

[0047] according to Figure 1 to Figure 7 , the first embodiment of the present invention will be described. In the present embodiment, the refrigeration cycle device 10 according to the present invention is applied to an electric vehicle in which a driving force for running the vehicle is obtained from a running electric motor. In addition, in the electric vehicle according to the present embodiment, the temperature of the secondary battery 55 (device) serving as a power storage device for performing air conditioning (cooling and heating) in the vehicle interior and storing electric power supplied to the electric motor for running is The refrigeration cycle device 10 is used for conditioning (heating and cooling).

[0048] More specifically, the refrigeration cycle device 10 functions to adjust the temperature of the indoor air blown to the vehicle interior, and also functions to adjust the temperature of the battery air blown to the secondary battery 55 . Features. In oth...

no. 2 approach

[0192] In this embodiment, the connection form of the 1st branch part 12a and the 1st three-way valve 14a is changed with respect to 1st Embodiment. Specifically, in this embodiment, as Figure 8 ~ Figure 14 The first three-way valve 14a is arranged on the refrigerant outlet side of the indoor condenser 13, and the first branch portion 12a connected to the first three-way valve 14a is arranged on the battery expansion valve 21 The refrigerant passage connecting the outlet side of the auxiliary heat exchanger 15 and the refrigerant inlet side of the auxiliary heat exchanger 15 .

[0193] Therefore, the first three-way valve 14a of this embodiment is used to switch the refrigerant flow path connecting the refrigerant outlet side of the indoor condenser 13 and the refrigerant inlet side of the first branch portion 12a, and to switch the refrigerant flow path connecting the indoor A refrigerant flow path that connects the refrigerant outlet side of the condenser 13 and one refrig...

no. 3 approach

[0228] In the first embodiment, an example of heating or cooling the battery supply air (gas) flowing in the air passage of the battery pack 50 as the second temperature adjustment object was described, but in the present embodiment, Such as Figure 15 As shown in the overall configuration diagram of , an example of heating or cooling the heating medium (liquid) flowing through the heating medium circuit 50a as the second temperature adjustment object will be described.

[0229] The heating medium circuit 50a is a circuit that circulates a heating medium (specifically, an aqueous ethylene glycol solution) that regulates the temperature of the secondary battery 55 . More specifically, the heating medium circuit 50a passes through the water pump 52a for pressure-feeding the heating medium, the heating medium passage formed inside or outside the secondary battery 55, and water for exchanging heat between the heating medium and the refrigerant. - The refrigerant heat exchanger 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com