Desaeration process of full desaeration system of chromatogram high-performance total analysis on-line monitoring device and desaeration system

A monitoring device and full analysis technology, applied in the field of degassing process and full degassing system, can solve the problems of complex structure, poor detection effect, dead oil in oil pipelines, etc., to achieve simple circulation structure, prolong service life, and avoid failures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below in conjunction with examples.

[0025] Best practice:

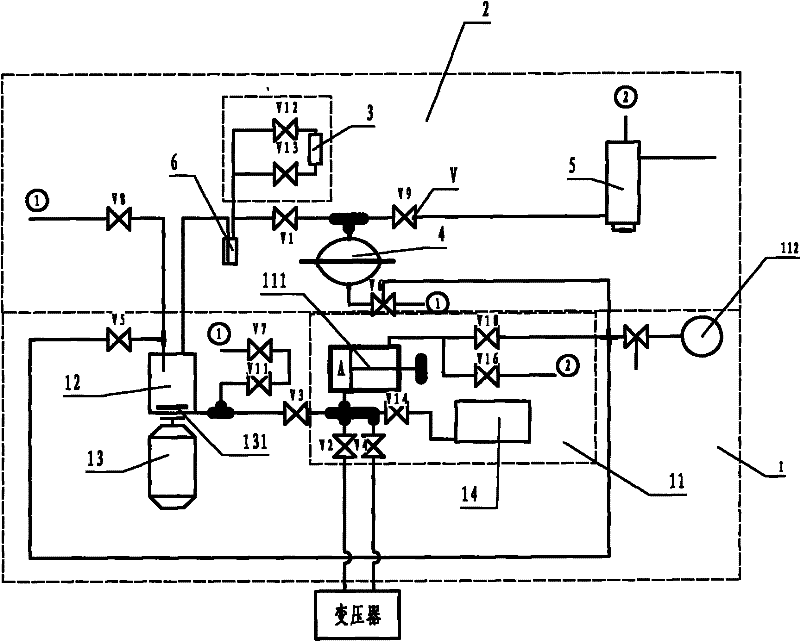

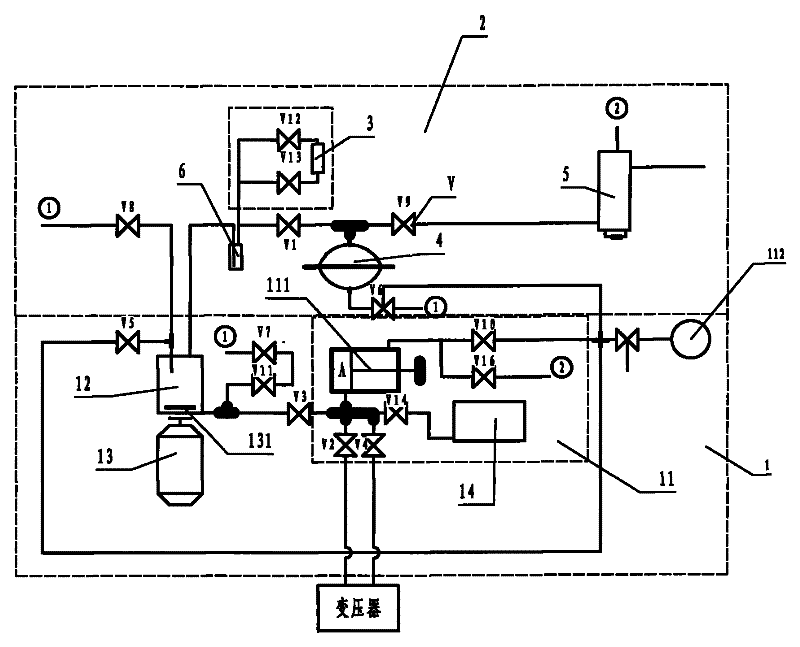

[0026] a kind of like figure 1 The full degassing system and degassing process of the chromatographic high-performance full-analysis online monitoring device for transformers shown. Including oil filter oil return system 1, online gas content detection system 2. The oil filtering and returning oil system includes an oil circuit circulation system 11, a degassing tank 12, an agitator 13, and an oil storage tank 14. The agitating member 131 of the agitator extends into the degassing tank, and the oil circuit The circulation system includes a cylinder 111 and a vacuum pump 112. The oil port of the cylinder is connected with the upper and lower oil outlets of the transformer through the oil pipeline. The vacuum pump is connected with the air port of the cylinder through the oil pipeline. It is also connected with the carrier gas system through the oil pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com