Mask for calibration and method for calibration

A mask and shielding line technology, applied in the field of correction masks and corrections, can solve problems such as complicated operations and difficult actual measurement of angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

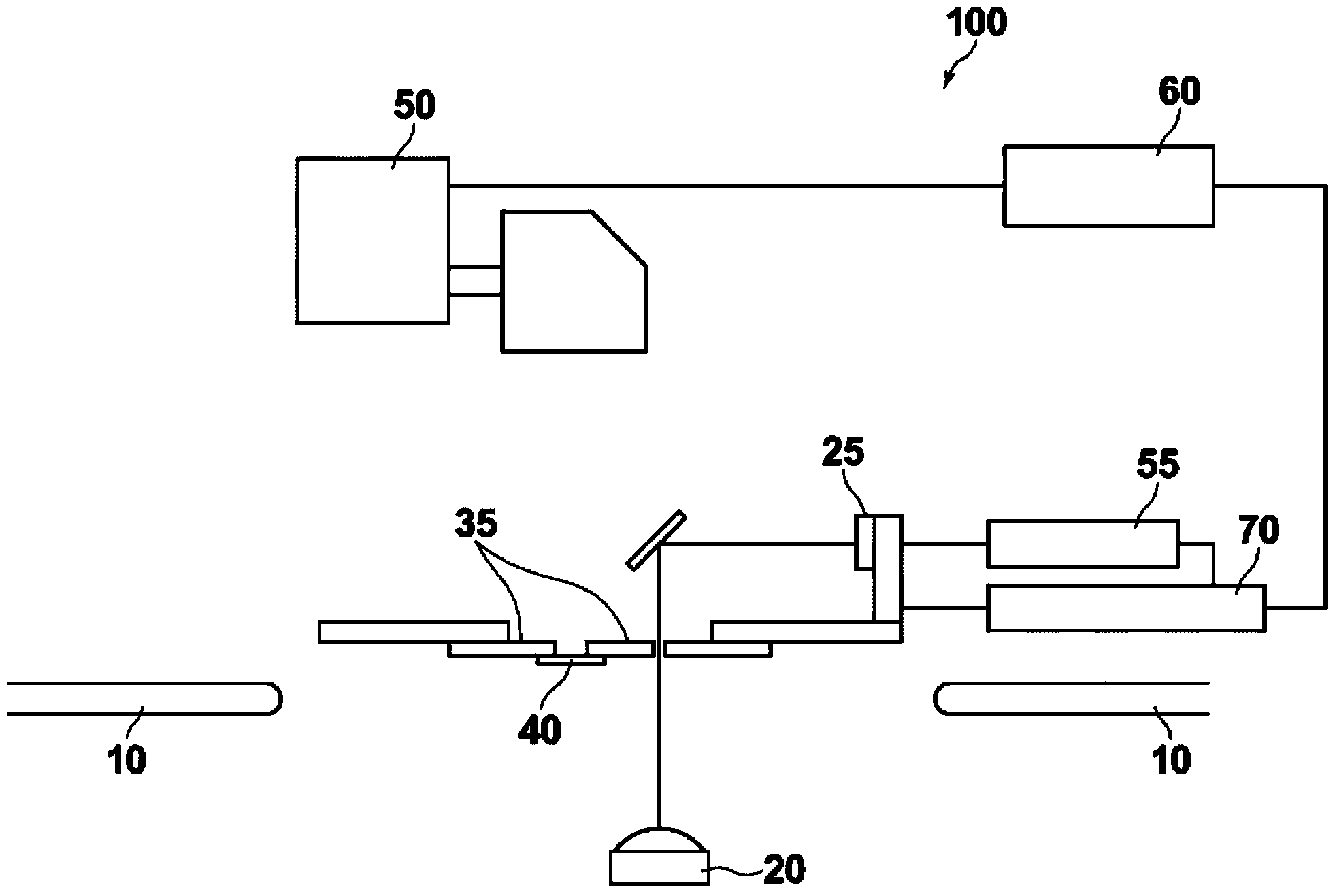

[0055] Refer below figure 1A calibration method for measuring the resolution of an image sensor for a calibration mask according to an embodiment of the present invention and an exposure device using the calibration mask.

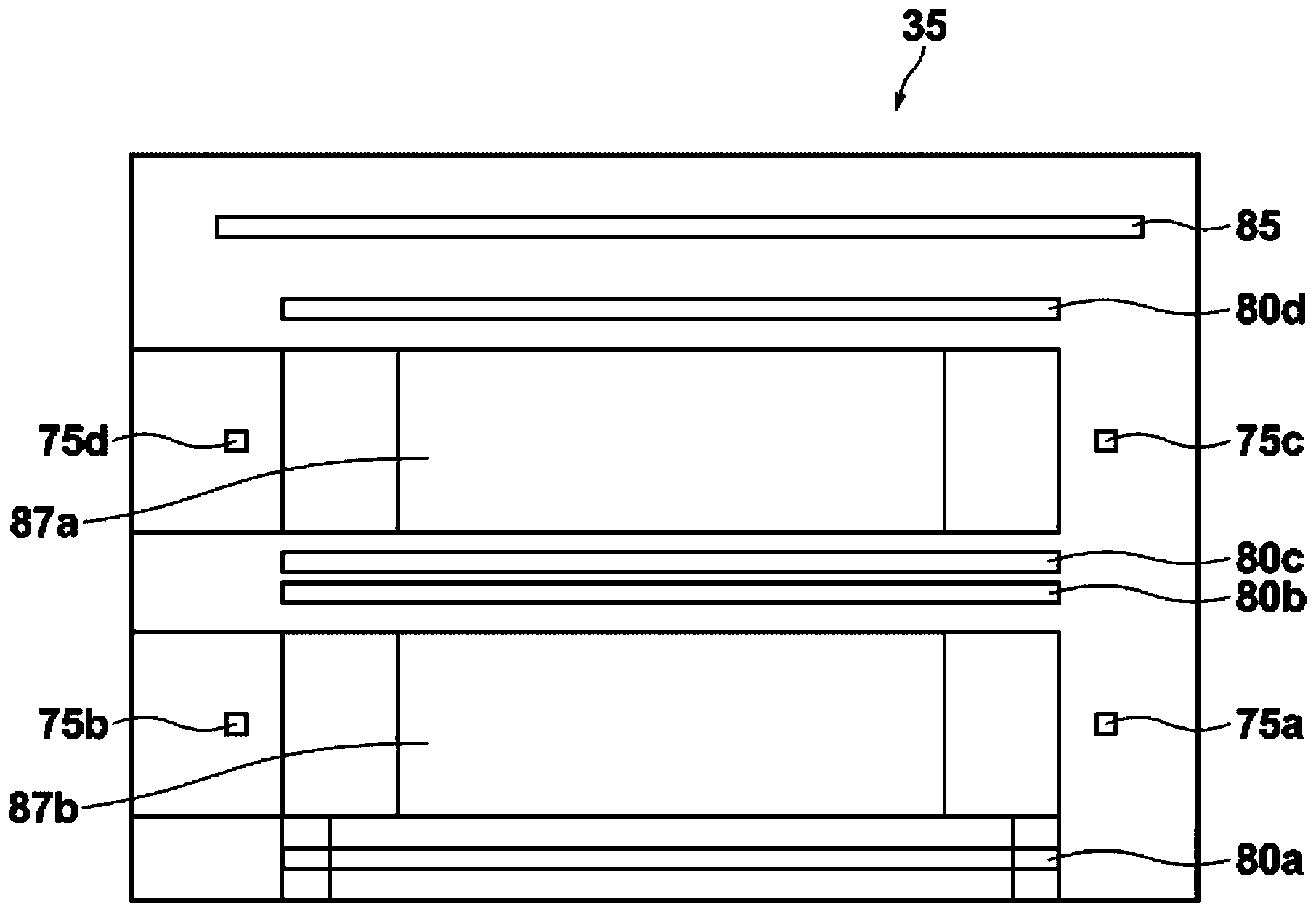

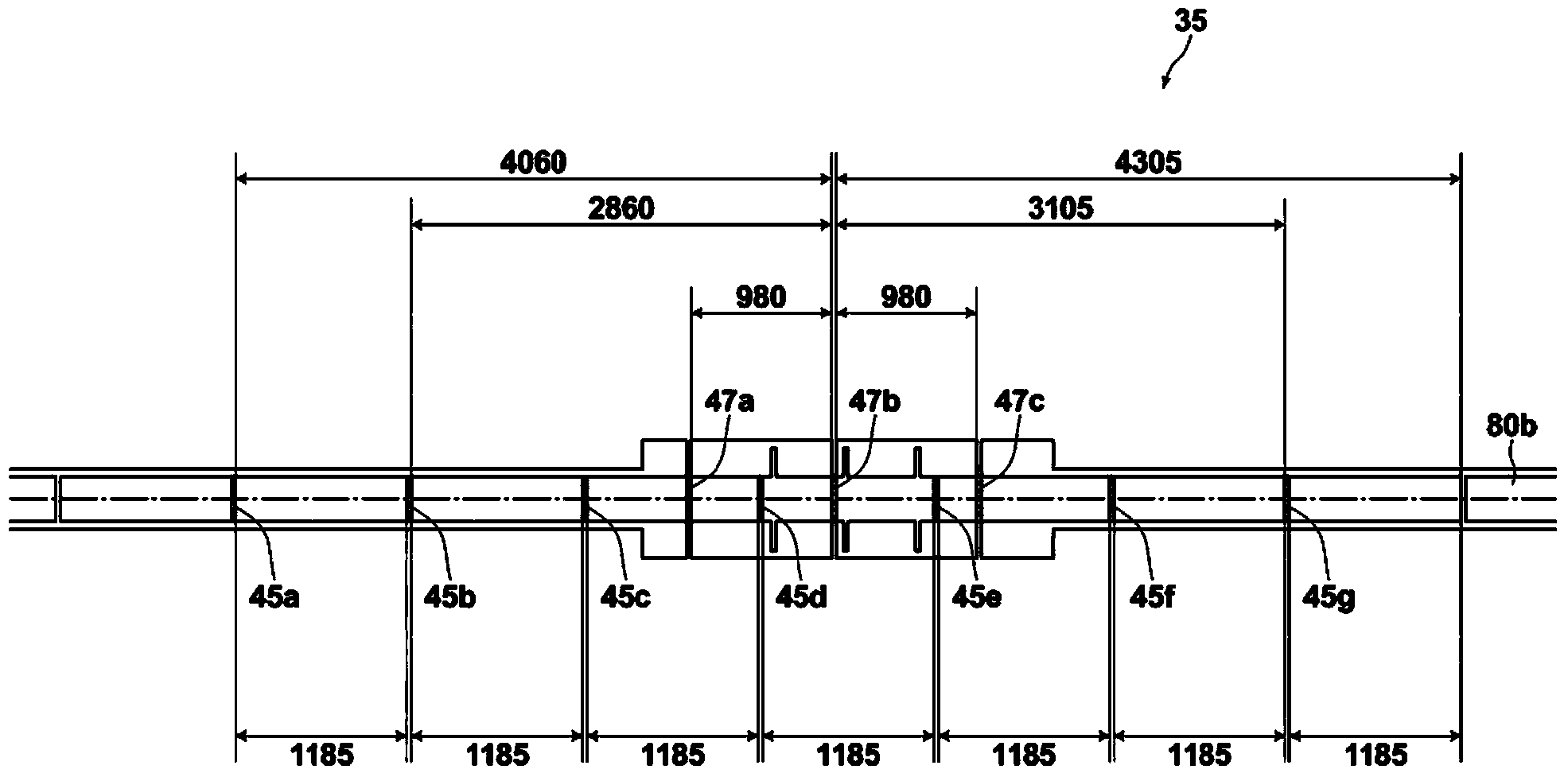

[0056] figure 2 It is a configuration diagram showing a correction mask portion 35 according to an embodiment of the present invention. The mask portion 35 has alignment marks 75a to 75d, image acquisition windows (line CCD observation windows) 80a to 80d, a mask ID 85, exposure windows 87a and 87b, and is arranged on the lower side of the image acquisition window 80 in a pasted manner as follows: Figure 4 The glass face 40 is shown. Such as Figure 5 As shown, the mask portion 35 is bonded to the glass portion 40 via an adhesive layer 49 . The glass surface portion 40 is located on the substrate side of the mask portion 35 and is made of a glass material adhered to the lower side near the image acquisition window 80 using an adhesive layer. The hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com