High-current switch

A high-current switch, electrical ground technology, applied in electrical switches, air switch parts, power devices inside switches, etc., can solve the problem of short switch life and achieve the effect of reliable closing or opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

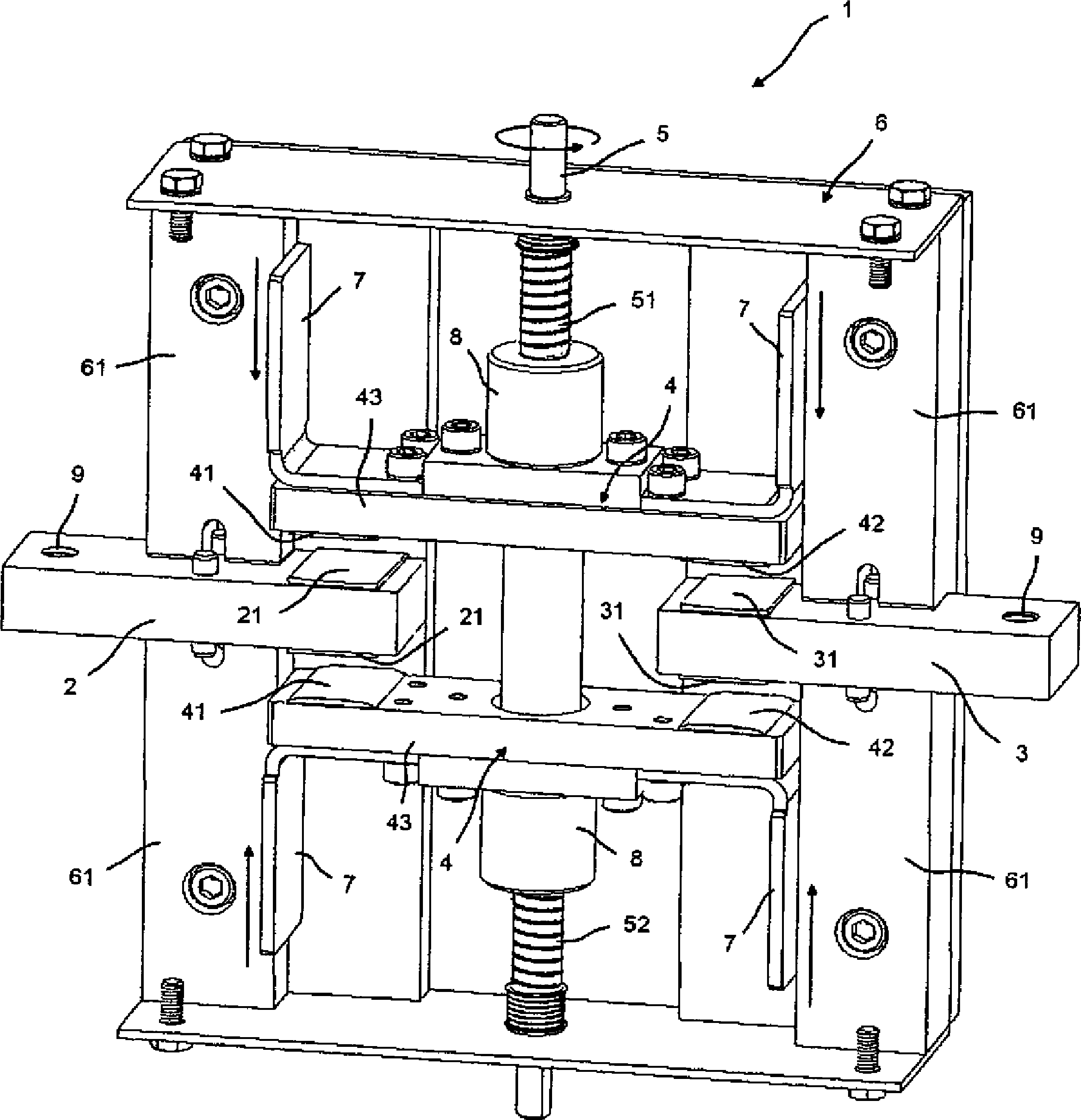

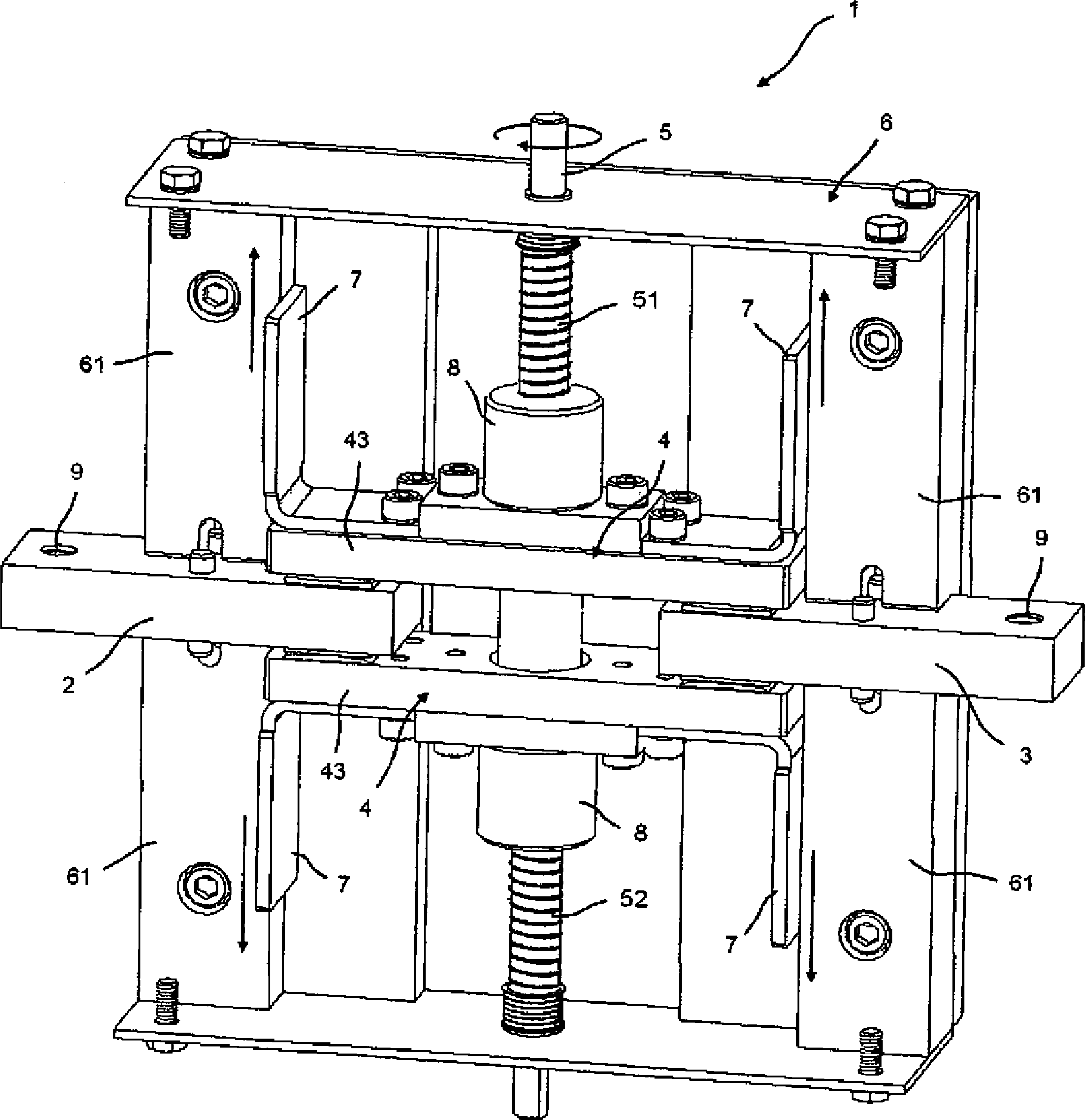

[0026] figure 1 and 2 Correspondingly in the closed position ( figure 1 ) and open position ( figure 2 ) shows an embodiment of a high current switch 1 according to the invention.

[0027] The housing 6 of the high-current switch 1 according to the invention is shown partly open, in order to allow observation of the internal structure of the switch.

[0028] The switch includes a first fixed contact 2 on the left and a second fixed contact 3 on the right. The two fixed contacts 2 and 3 are mounted at a distance from one another in the housing 6 of the switch 1 , wherein one end of the fixed contact 2 or 3 respectively protrudes from the housing 6 . Correspondingly, an electrical connection 9 is provided at this end, so that the switch 1 can be integrated into the circuit to be switched.

[0029] On switch 1 in the figure 1 In the closed position shown in , the two fixed contacts 2 and 3 are electrically connected to each other via two contact bridges 4 . Each of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com